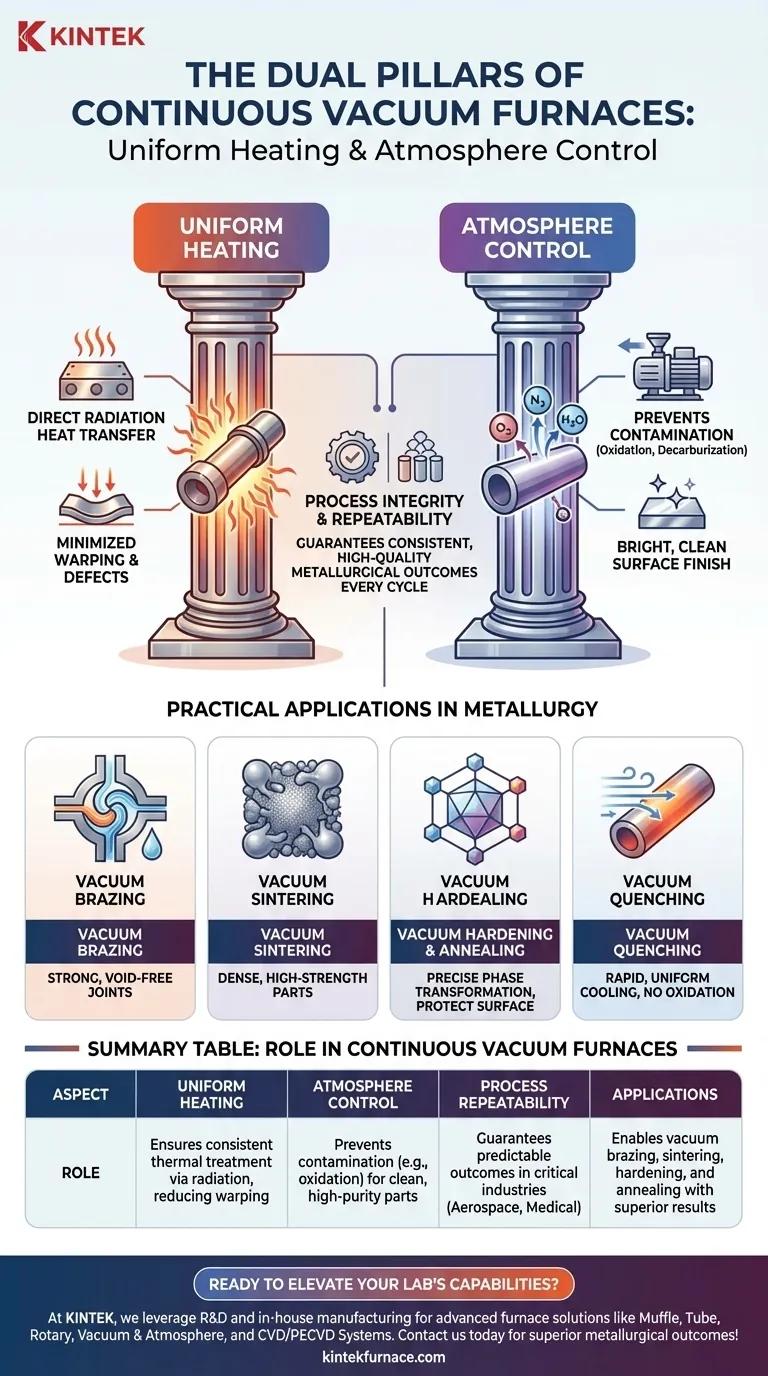

At their core, uniform heating and atmosphere control are the twin pillars of process integrity in continuous vacuum furnaces. They work in tandem to guarantee repeatable, high-quality metallurgical outcomes by ensuring every part of a component experiences the exact same thermal cycle in an environment free of reactive contaminants like oxygen.

The fundamental challenge in high-performance material treatment is not just reaching a target temperature, but ensuring every surface and internal section of the material experiences the exact same conditions. Uniform heating and atmosphere control are the mechanisms that transform a simple oven into a precision instrument for engineering specific, predictable material properties.

The Core Functions: Why Control Matters

In any thermal process, consistency is the goal. A vacuum furnace uses these two principles to eliminate the variables that lead to defects and inconsistent quality in finished parts.

Achieving True Thermal Uniformity

In a conventional furnace, heat is primarily transferred via convection (moving air). This can lead to hot and cold spots, causing uneven treatment.

A vacuum environment fundamentally changes heat transfer. By removing most of the air, heat is transferred primarily through radiation, which travels in straight lines from the heating elements to the parts. This allows for a much more direct and uniform heating profile, minimizing the risk of warping or inconsistent metallurgical transformations.

Mastering the Atmosphere: Preventing Contamination

The "atmosphere control" in a vacuum furnace is the vacuum itself. By pumping out the air, we remove reactive gases like oxygen, nitrogen, and water vapor.

This is critical because at high temperatures, these gases aggressively react with metal surfaces. A vacuum prevents harmful reactions like oxidation (rusting), decarburization (loss of surface hardness), and the formation of other undesirable surface layers. The result is a bright, clean part that requires no post-process cleaning.

Ensuring Process Repeatability

When every component in a batch—and every subsequent batch—is subjected to the identical thermal profile and the identical pure atmosphere, the results become highly predictable. This level of control is essential for industries like aerospace, medical, and automotive, where material failure is not an option and strict quality assurance standards must be met.

Practical Applications in Metallurgy

The combination of uniform heat and a pure environment enables several high-precision processes that are difficult or impossible to achieve otherwise.

Vacuum Brazing and Sintering

Brazing joins two pieces of metal using a filler metal. In a vacuum, the absence of oxides on the base metals allows the filler metal to flow cleanly and create an exceptionally strong, pure, and void-free joint.

Sintering fuses metal powders into a solid part. The vacuum prevents oxidation on the individual powder grains, allowing for direct metal-to-metal diffusion and bonding, which results in a dense, high-strength final component.

Vacuum Hardening and Annealing

Processes like hardening and annealing rely on heating metals to precise temperatures to alter their crystalline structure. Uniform heating ensures the entire part undergoes the desired phase transformation correctly. The vacuum protects the part's surface integrity during these long, high-temperature cycles.

Vacuum Quenching

After heating, parts are often cooled rapidly (quenched) to lock in hardness. In a vacuum furnace, this is typically done by back-filling the chamber with a high-pressure inert gas like argon or nitrogen. This provides rapid, uniform cooling without the thermal shock and oxidation associated with liquid quenching.

Understanding the Trade-offs: Vacuum vs. Atmosphere Furnaces

While powerful, a continuous vacuum furnace is not the universal solution for all heat-treating needs. Understanding its trade-offs compared to a traditional atmosphere furnace (which uses controlled gas mixtures instead of a vacuum) is key.

Process Purity vs. Throughput

Pulling a deep vacuum takes time. This "pump-down" cycle means that for simple, non-reactive materials, a continuous-belt atmosphere furnace can often achieve higher throughput. The trade-off is a vastly superior surface finish and material purity from the vacuum process.

Cost and Complexity

Vacuum furnaces are inherently more complex and expensive to build and maintain. They require robust vacuum pumps, precise seals, and sophisticated control systems. The investment is justified when processing high-value, reactive, or performance-critical materials that would be compromised in a less-controlled environment.

Environmental and Safety Advantages

Continuous vacuum furnaces are exceptionally clean. They produce no products of combustion and eliminate the need to store and handle some of the more hazardous or flammable gas mixtures used in atmosphere furnaces, improving workplace safety and environmental compliance.

Making the Right Choice for Your Goal

The decision to use a vacuum process depends entirely on the material being treated and the desired final outcome.

- If your primary focus is high-volume, low-cost treatment of non-reactive steels: A traditional atmosphere furnace is often more cost-effective and efficient.

- If your primary focus is joining complex assemblies or processing reactive materials like titanium: The purity of a continuous vacuum furnace is non-negotiable to prevent component failure.

- If your primary focus is achieving maximum hardness with a bright, clean surface finish: Vacuum hardening followed by gas quenching provides superior results by eliminating all surface oxidation.

- If your primary focus is producing dense, high-purity parts from metal powders: Vacuum sintering is essential for preventing contamination and ensuring strong, reliable particle bonding.

Ultimately, mastering uniform heating and atmosphere control allows you to move from simply heating metal to precisely engineering its final form and function.

Summary Table:

| Aspect | Role in Continuous Vacuum Furnaces |

|---|---|

| Uniform Heating | Ensures consistent thermal treatment via radiation, reducing warping and defects |

| Atmosphere Control | Prevents contamination (e.g., oxidation, decarburization) for clean, high-purity parts |

| Process Repeatability | Guarantees predictable outcomes in critical industries like aerospace and medical |

| Applications | Enables vacuum brazing, sintering, hardening, and annealing with superior results |

Ready to elevate your lab's capabilities with precision high-temperature solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. Our deep customization ensures they meet your unique experimental needs for uniform heating and atmosphere control. Contact us today to discuss how we can help you achieve superior metallurgical outcomes!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- What is the heat treatment in a vacuum furnace? Achieve Superior Metallurgical Properties

- Why use a vacuum furnace? Achieve Unparalleled Material Purity and Process Control

- How does a vacuum furnace prevent heat transfer and contamination? Achieve Ultimate Material Purity

- What does a vacuum furnace do? Achieve Superior Material Processing in a Pure Environment

- What is the process of vacuum heat treatment? Achieve Superior Metallurgical Properties