At its core, the RF power supply is the engine of the Plasma-Enhanced Chemical Vapor Deposition (PECVD) process. It provides the high-frequency electrical energy required to transform inert precursor gases into a reactive plasma, which is the fundamental state needed to deposit a thin film onto a substrate. Without the RF power supply, no plasma is generated, and no deposition occurs.

The true role of the RF power supply extends far beyond simply turning the system "on." It is the primary control lever for manipulating the plasma's characteristics, which directly dictates the final properties of the deposited thin film, including its deposition rate, density, stress, and uniformity.

The Fundamental Role: From Gas to Plasma

To understand its importance, we must first visualize how the RF power supply initiates the deposition process. It's a three-step sequence of energy transfer.

Generating the Electric Field

A PECVD chamber contains at least two electrodes. The RF power supply creates a rapidly oscillating electric field between these electrodes. The substrate, on which the film will be grown, is placed on one of these electrodes.

Igniting the Plasma

As precursor gases flow into the chamber, this intense electric field energizes free electrons within the gas. These energized electrons collide with the neutral gas molecules, transferring energy and knocking off other electrons in an avalanche effect.

Creating Reactive Species

This cascade of collisions breaks down the stable gas molecules into a mix of ions (charged atoms) and highly reactive free radicals (neutral fragments). This energized gas mixture is the plasma, and it contains the chemical building blocks that will ultimately form the thin film on the substrate surface.

The Critical Distinction: High vs. Low Frequency

The frequency of the RF power is not a minor detail; it fundamentally changes the nature of the plasma and is a critical parameter for process control. Most advanced PECVD systems use a dual-frequency approach.

High Frequency (HF): For Deposition Rate

Standard HF power supplies operate at 13.56 MHz. At this high frequency, the lightweight electrons can easily follow the oscillating electric field, leading to numerous collisions and efficient creation of free radicals. Heavier ions cannot keep up.

This high concentration of free radicals results in a higher deposition rate. However, it also has a strong influence on the intrinsic stress of the film.

Low Frequency (LF): For Film Density and Coverage

LF power supplies operate at much lower frequencies (typically < 500 kHz). At these slower oscillations, the heavier positive ions have enough time to accelerate and gain significant energy before the field reverses.

This results in high-energy ion bombardment of the substrate surface. This bombardment creates denser, more compact films and can improve step coverage—the ability to coat the sidewalls of trenches and complex surface features.

Understanding the Trade-offs

Simply increasing power or choosing a frequency is not a solution. The RF power supply's settings involve a series of critical trade-offs that every process engineer must manage.

Power vs. Deposition Rate

Increasing RF power generally increases the concentration of reactive species in the plasma, leading to a faster deposition rate. This improves throughput.

However, after a certain point, the precursor gas becomes fully dissociated. Any further increase in power yields no increase in deposition rate—this is the saturation point. Pushing power beyond this point only adds energy, potentially damaging the substrate or the film.

Power vs. Film Quality

Higher power leads to higher ion bombardment energy. A moderate level of bombardment is beneficial, creating denser and more robust films.

Excessive bombardment, however, can introduce defects, increase compressive stress to undesirable levels, or even sputter (physically knock away) the film you are trying to deposit.

Frequency vs. Film Properties

Using only HF power can result in fast deposition but may produce films that are less dense or have high tensile stress. Using only LF power can create very dense films but may also induce damage and typically results in a slower deposition rate. This is why many modern recipes blend HF and LF power to balance these effects.

Matching the RF Strategy to Your Film Goal

Your choice of RF parameters should be driven entirely by the desired outcome for your thin film. There is no single "best" setting; there is only the best setting for your specific application.

- If your primary focus is maximizing deposition rate: Use high RF power at a high frequency (HF), but operate just below the saturation point to remain efficient and avoid damage.

- If your primary focus is achieving a dense, high-quality film: Incorporate low frequency (LF) power to increase ion bombardment energy, which compacts the growing film.

- If your primary focus is managing film stress: Carefully tune the ratio of HF to LF power, as HF primarily influences stress while LF can be used to modify film density.

- If your primary focus is coating complex topographies (step coverage): Emphasize LF power to increase the directionality of ion bombardment, which helps drive depositing species onto feature sidewalls.

Ultimately, mastering the RF power supply is the key to transforming PECVD from a simple coating process into a precise materials engineering tool.

Summary Table:

| Parameter | Effect on PECVD Process |

|---|---|

| RF Power | Controls deposition rate and film quality; higher power increases rate but may cause damage beyond saturation |

| High Frequency (HF) | Enhances deposition rate and influences film stress; operates at 13.56 MHz for efficient free radical generation |

| Low Frequency (LF) | Improves film density and step coverage; operates below 500 kHz for high-energy ion bombardment |

| Dual-Frequency | Balances HF and LF to optimize film properties like stress, density, and uniformity |

Unlock the full potential of your PECVD processes with KINTEK's advanced solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace systems, including CVD/PECVD Systems, Muffle, Tube, Rotary Furnaces, and Vacuum & Atmosphere Furnaces. Our strong deep customization capability ensures precise alignment with your unique experimental needs, helping you achieve superior thin film deposition with optimized RF power control. Contact us today to discuss how we can enhance your lab's efficiency and results!

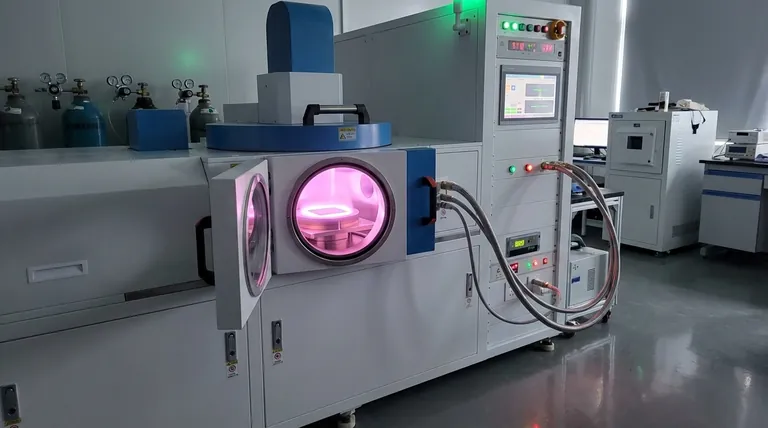

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Spark Plasma Sintering SPS Furnace

People Also Ask

- What is plasma enhanced chemical vapor deposition application? Enable High-Performance Thin Films at Lower Temperatures

- How does plasma vapor deposition work? A Low-Temperature Solution for Advanced Coatings

- How does plasma enhanced CVD work? Achieve Low-Temperature, High-Quality Thin Film Deposition

- Is PECVD directional? Understanding Its Non-Line-of-Sight Advantage for Complex Coatings

- What is the second benefit of deposition within a discharge in PECVD? Enhance Film Quality with Ion Bombardment