In short, tube plugs and thermal fixtures are essential accessories used in vertical tube furnaces to precisely control the thermal environment. Their primary roles are to improve temperature uniformity by minimizing heat loss and to enhance the furnace's versatility by allowing it to accommodate a wider variety of tube sizes and sample configurations.

These components address the fundamental challenge of open-tube heating: heat escaping from the ends. By managing this heat loss, plugs and fixtures transform a standard furnace into a more precise instrument, ensuring the thermal conditions your process requires are stable, uniform, and repeatable.

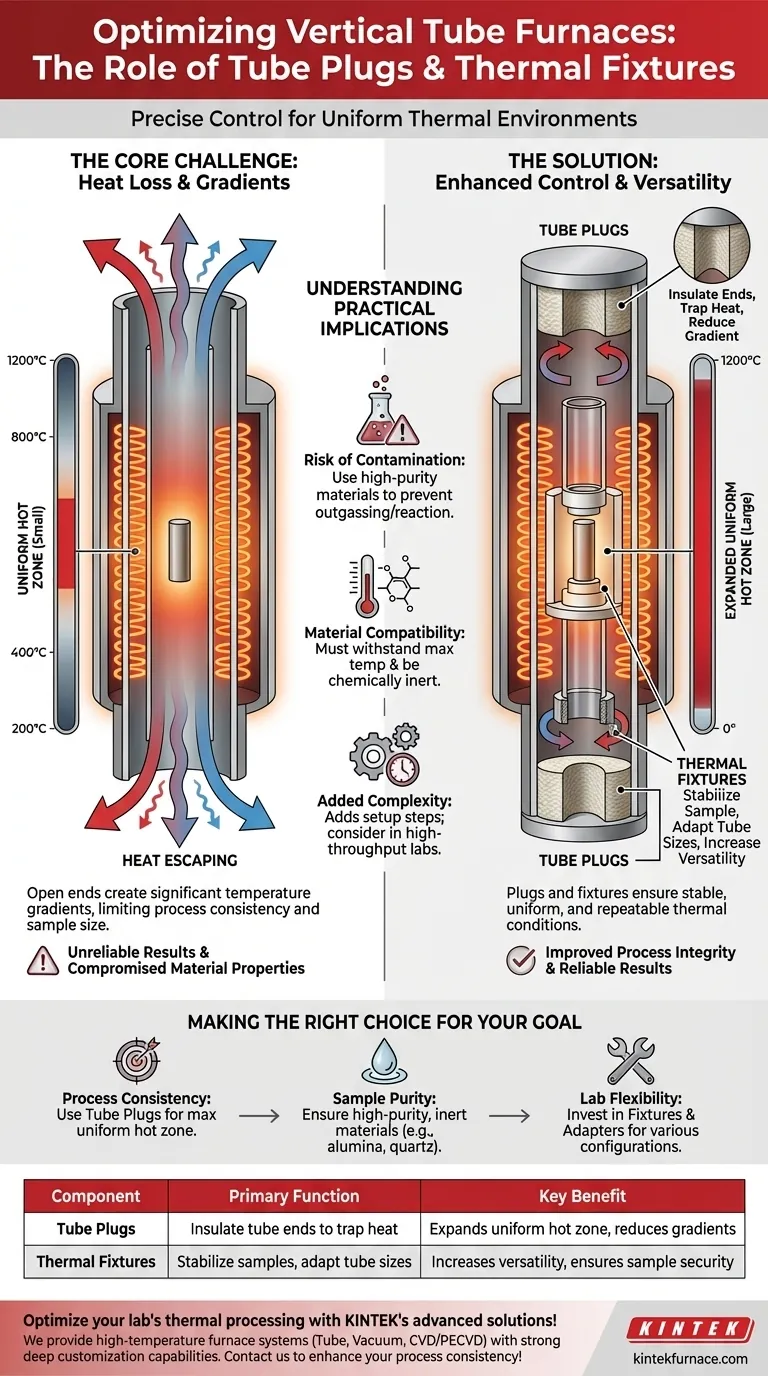

The Core Challenge: Heat Loss and Gradients

A vertical tube furnace works by surrounding a central tube with heating elements. While this design is efficient, the open nature of the tube creates an inherent problem.

Understanding Temperature Gradients

Heat naturally escapes from the ends of the tube, a phenomenon that creates a temperature gradient. This means the center of the tube will be at your target temperature, but the temperature will drop off significantly toward the top and bottom openings.

This gradient results in a very small "uniform hot zone," limiting the area where a sample can be heated consistently.

The Impact on Process Integrity

For many applications in materials science, chemistry, and manufacturing, this inconsistency is unacceptable.

Processes like crystal growth, annealing, or catalytic reactions demand precise and uniform thermal conditions. If different parts of your sample are exposed to different temperatures, the results can be unreliable, and the final material properties may be compromised.

How Plugs and Fixtures Provide Control

Tube plugs and thermal fixtures are the tools used to counteract these natural thermal inefficiencies and regain control over the heating environment.

Tube Plugs: Insulating the Ends

Tube plugs are essentially high-temperature insulators, often made of ceramic fiber or refractory materials, that are inserted into the ends of the work tube.

Their function is simple but critical: they trap heat inside the tube. By blocking the primary path of heat loss, they dramatically reduce the temperature gradient and significantly expand the length of the uniform hot zone.

Thermal Fixtures: Stabilizing and Adapting

Thermal fixtures is a broader category that includes components like sample holders, spacers, or adapters.

These fixtures serve two main purposes. First, they ensure your sample is securely positioned in the most stable part of the hot zone. Second, they can act as adapters, allowing a large-diameter furnace to be used with smaller-diameter work tubes, which enhances the versatility and cost-effectiveness of your equipment.

Understanding the Practical Implications

While essential, integrating these components requires careful consideration to avoid introducing new problems.

Risk of Contamination

Any object placed inside the furnace tube is a potential source of contamination. Plugs and fixtures must be made from high-purity materials that will not outgas or react with your sample or process atmosphere at high temperatures.

Material Compatibility

The materials used for plugs and fixtures must be able to withstand the maximum process temperature without degrading. They must also be chemically inert to any reactive gases or materials used in your experiment.

Added Complexity

Using these accessories adds steps to your process setup and breakdown. While usually a minor inconvenience, it is a factor to consider in high-throughput environments.

Making the Right Choice for Your Goal

Properly selecting and implementing these components is key to optimizing your furnace for目标 performance.

- If your primary focus is process consistency: Always use tube plugs to minimize temperature gradients and create the largest possible uniform hot zone for your sample.

- If your primary focus is sample purity: Ensure your plugs and fixtures are made from high-purity, chemically inert materials like alumina or quartz, and are properly cleaned before use.

- If your primary focus is lab flexibility: Invest in a set of thermal fixtures and adapter rings that can configure your furnace for various tube and sample sizes, maximizing the utility of your equipment.

Ultimately, mastering the use of these accessories is what elevates a vertical tube furnace from a simple heater to a precision thermal processing tool.

Summary Table:

| Component | Primary Function | Key Benefit |

|---|---|---|

| Tube Plugs | Insulate tube ends to trap heat | Expands uniform hot zone and reduces temperature gradients |

| Thermal Fixtures | Stabilize samples and adapt tube sizes | Increases furnace versatility and ensures sample security |

Optimize your lab's thermal processing with KINTEK's advanced solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace systems, including Tube Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs. Contact us today to discuss how our tailored furnace accessories can enhance your process consistency and efficiency!

Visual Guide

Related Products

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What industrial and research applications are tube furnaces used for? Unlock Precise Thermal Processing Solutions

- What is the working principle of a vacuum tube furnace? Master Precise High-Temperature Processing

- What is the primary function of a vacuum-sealed quartz tube in MnBi2Te4 growth? Ensure High-Purity Crystal Synthesis

- Why is a high-precision vacuum tube furnace essential for CVD graphene? Master Growth Control & Purity

- What materials are used for the tubes in a High Temperature Tube Furnace? Choose the Right Tube for Your Lab