At its core, an electric rotary kiln is a highly versatile thermal processing tool capable of handling a vast array of materials. These kilns are engineered to process everything from fine powders and granules to larger, inconsistent feedstocks, making them suitable for producing advanced materials like catalysts and battery components, refining minerals and metals, and recycling various waste streams.

The key to understanding a rotary kiln's capability is not just the material's chemical name, but its physical form and the precise thermal treatment it requires. Electric kilns excel where uniform heating, strict temperature control, and a clean processing environment are critical to the final product's quality.

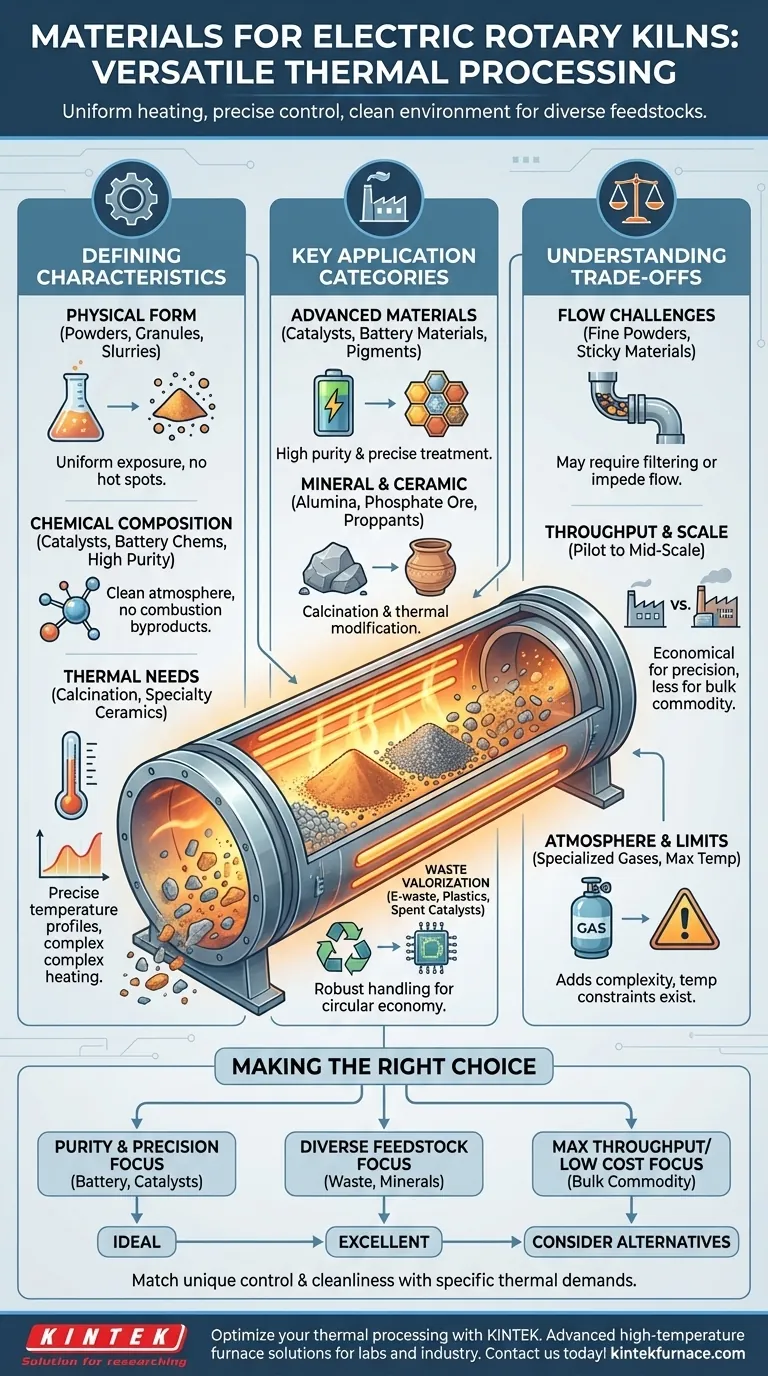

The Defining Characteristics of Suitable Materials

An electric rotary kiln's suitability for a material is defined by its physical properties, chemical nature, and the specific heat treatment required. The kiln's design leverages a gentle tumbling action within a controlled-temperature tube.

Physical Form: Powders, Granules, and Suspensions

The rotating drum is exceptionally effective at processing solid materials. The continuous tumbling ensures every particle is uniformly exposed to the heat source, preventing hot spots and ensuring a consistent reaction or phase change.

This makes them ideal for powders, granulates, slurries, and even certain green bodies (unfired ceramic or metal parts). The design inherently handles materials with varying particle sizes and moisture levels.

Chemical and Mineralogical Composition

Electric rotary kilns are used across a wide spectrum of chemical families due to their controlled, non-contaminating heating method. Since there are no combustion byproducts, the process atmosphere remains clean, which is essential for high-purity applications.

This includes materials like catalysts, lithium battery chemicals (e.g., lithium iron phosphate), pigments, various metal oxides (alumina, bauxite), and precious metals.

Specific Thermal Processing Needs

Electric heating elements provide unparalleled precision in temperature control. This allows for complex heating profiles, including specific ramp-up rates, holding times (residence times), and cooling profiles.

This precision is critical for processes like calcination, where a material's chemical structure is changed through heat, or for creating specialty ceramics and alloys with specific crystalline structures.

Key Application Categories and Examples

Based on these characteristics, materials processed in electric rotary kilns fall into several major industrial categories.

Advanced Materials & Specialty Chemicals

This is where electric kilns shine. The need for high purity and precise thermal treatment makes them the preferred choice for producing high-value materials.

Examples include:

- Catalysts and Catalyst Supports

- Battery Materials (both for production and recycling)

- Adsorbents and Polishing Agents

- Specialty Pigments

Mineral and Ceramic Processing

Electric kilns are widely used for the calcination and thermal modification of minerals and the creation of ceramic products.

Examples include:

- Alumina and Bauxite

- Phosphate Ore

- Beta Spodumene and other lithium-bearing minerals

- Ceramic Precursors and Proppants

Waste Valorization and Recycling

The kiln's robustness and ability to handle heterogeneous feedstock make it a powerful tool for the circular economy.

Examples include:

- Electronic Waste (E-waste) for metal recovery

- Plastic Waste for pyrolysis

- Waste Lime Sludge for recalcination

- Spent Catalysts for regeneration or metal recovery

Understanding the Trade-offs

While highly versatile, electric rotary kilns are not a universal solution. Understanding their limitations is key to making a sound technical decision.

Material Flow Challenges

Extremely fine powders may become entrained in the process gas, requiring downstream filtering. Conversely, materials that are very sticky or tend to agglomerate at process temperatures can build up on the kiln walls, impeding flow and heat transfer.

Throughput and Economic Scale

Electric kilns can be designed for capacities ranging from small pilot-scale batches to over 20 tons per hour. However, for extremely high-volume, low-margin bulk materials (like cement), the lower operational cost of a large, direct-fired kiln is often more economical.

Atmosphere and Temperature Limits

The primary advantage of an electric kiln is its clean, controlled atmosphere. However, achieving and maintaining specialized atmospheres (e.g., pure hydrogen, inert nitrogen) adds complexity and cost. The maximum temperature is also a design constraint determined by the heating elements and shell materials, which can be a limiting factor compared to some fuel-fired systems.

Making the Right Choice for Your Material

Selecting the right thermal processing technology requires aligning the equipment's strengths with your primary objective.

- If your primary focus is material purity and precision: An electric rotary kiln is ideal for battery materials, catalysts, and specialty chemicals where a contamination-free, precisely controlled heating profile is non-negotiable.

- If your primary focus is processing diverse or inconsistent feedstock: The kiln's ability to handle varying sizes, moisture levels, and compositions makes it excellent for waste recycling and raw mineral processing.

- If your primary focus is maximum throughput at the lowest cost: You must weigh the operational control of an electric kiln against the scale and fuel economics of a direct-fired system, especially for commodity materials.

Ultimately, the decision rests on matching the unique control and cleanliness of an electric kiln with the specific thermal demands of your material.

Summary Table:

| Material Type | Examples | Key Applications |

|---|---|---|

| Powders & Granules | Catalysts, Battery Materials | Advanced Materials, Specialty Chemicals |

| Minerals & Ceramics | Alumina, Phosphate Ore | Calcination, Ceramic Processing |

| Waste Streams | E-waste, Plastic Waste | Recycling, Valorization |

| Specialty Forms | Slurries, Green Bodies | Uniform Heating, High Purity Processes |

Ready to optimize your thermal processing with precision and reliability? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for laboratories and industrial applications. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental needs—whether you're working with catalysts, battery materials, minerals, or waste streams. Contact us today to discuss how our solutions can enhance your material processing efficiency and purity!

Visual Guide

Related Products

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What advantages do electrically heated rotary kilns offer in temperature control? Achieve Precision and Uniformity for Superior Results

- What are some drying applications of electromagnetic rotary kilns? Discover Efficient, Precise Drying Solutions

- What are the uses of rotary kilns in the building materials industry besides cement clinker? Key Applications Explained

- Why is a Rotary Kiln specifically suitable for treating high-carbon FMDS? Turn Waste Carbon into a Resource

- How is bed depth controlled in a rotary kiln and why is it important? Optimize Heat Transfer and Efficiency