Muffle furnaces are a cornerstone of effective heat treatment due to their unique ability to deliver precise temperature control, uniform heating, and a chemically isolated atmosphere. This combination is essential for controllably altering the physical properties of materials like metals and alloys, which is the entire purpose of processes such as annealing, hardening, and tempering.

The defining feature of a muffle furnace is its internal chamber—the ‘muffle’—which separates the material being treated from the heating elements. This physical separation is the key to preventing contamination and achieving the precise, uniform thermal conditions required to predictably alter a material's microstructure.

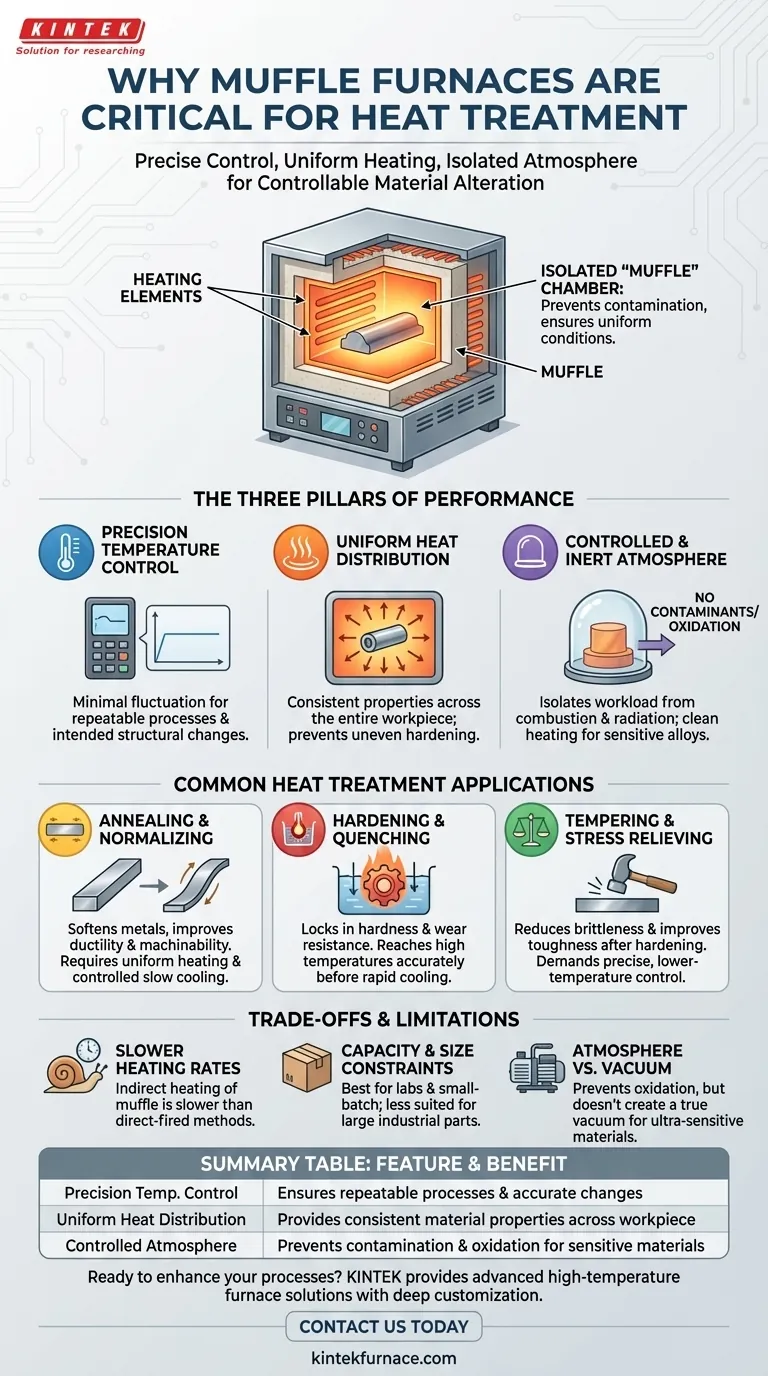

The Three Pillars of Muffle Furnace Performance

The suitability of a muffle furnace for heat treatment is not based on a single feature, but on the interplay of three critical capabilities.

Pillar 1: Precision Temperature Control

Achieving a specific material property, like hardness or ductility, depends on reaching and holding an exact temperature for a set duration.

A muffle furnace's electronic controller and insulated chamber allow for minimal temperature fluctuation. This precision ensures that processes are repeatable and that the material undergoes the intended structural change.

Pillar 2: Uniform Heat Distribution

If a part is heated unevenly, its properties will be inconsistent. One section might be hard and brittle while another remains soft.

The muffle, typically made of a refractory ceramic, heats up and radiates energy evenly onto the workpiece from all sides. This ensures the entire component reaches the target temperature simultaneously, resulting in uniform material properties.

Pillar 3: Controlled and Inert Atmosphere

The "muffle" itself is a sealed inner chamber that isolates the workload from the furnace's heating elements.

This separation prevents contamination from combustion byproducts or direct element radiation, which can cause undesirable surface reactions like oxidation. For many sensitive alloys, this clean heating environment is non-negotiable.

Common Heat Treatment Applications

Different thermal processes leverage these capabilities to achieve specific outcomes.

Annealing and Normalizing

These processes are used to soften metals, improve their ductility, and relieve internal stresses, making them easier to machine or form.

Success requires uniform heating and a very controlled, often slow, cooling rate, which the insulated chamber of a muffle furnace facilitates perfectly.

Hardening and Quenching

Hardening involves heating a metal above a critical temperature and then rapidly cooling it (quenching) to lock in a hard, wear-resistant crystalline structure.

A muffle furnace provides the ability to reach these high temperatures accurately without damaging the material's surface, preparing it for a successful quench.

Tempering and Stress Relieving

After hardening, a metal is often too brittle for practical use. Tempering is a subsequent, lower-temperature heat treatment that reduces this brittleness and improves toughness.

This process demands the precise temperature control that muffle furnaces are known for, as even small deviations can ruin the balance between hardness and toughness.

Understanding the Trade-offs and Limitations

While highly effective, muffle furnaces are not the universal solution for all thermal processing.

Slower Heating Rates

The muffle itself must be heated before it can radiate energy to the workload. This indirect heating method is generally slower than that of direct-fired or induction furnaces.

Capacity and Size Constraints

Muffle furnaces are most common in laboratories and for small-batch production. Their design is less suited for processing very large or irregularly shaped industrial components.

Atmosphere vs. Vacuum

While a muffle provides a clean, controlled atmosphere and prevents oxidation from ambient air, it does not create a true vacuum. For the most sensitive materials that require a complete absence of atmospheric gases, a dedicated vacuum furnace is the superior choice.

Making the Right Choice for Your Goal

Your specific objective determines which furnace feature is most critical.

- If your primary focus is improving ductility and machinability: Annealing is your process, requiring the uniform heat and slow, controlled cooling that a well-insulated muffle furnace provides.

- If your primary focus is maximizing hardness and wear resistance: A hardening and tempering cycle is necessary, leveraging the furnace's ability to achieve and hold precise high and subsequent lower temperatures.

- If your primary focus is preventing surface oxidation or contamination: The muffle's isolated chamber is the critical feature, making it superior to direct-fired alternatives for sensitive materials.

Ultimately, the muffle furnace excels by providing a stable, clean, and predictable thermal environment, empowering you to reliably engineer the desired properties into your materials.

Summary Table:

| Feature | Benefit for Heat Treatment |

|---|---|

| Precision Temperature Control | Ensures repeatable processes and accurate material property changes |

| Uniform Heat Distribution | Provides consistent material properties across the entire workpiece |

| Controlled Atmosphere | Prevents contamination and oxidation for sensitive materials |

Ready to enhance your heat treatment processes with reliable, high-performance furnaces? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Contact us today to discuss how we can tailor a solution for your specific needs!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure