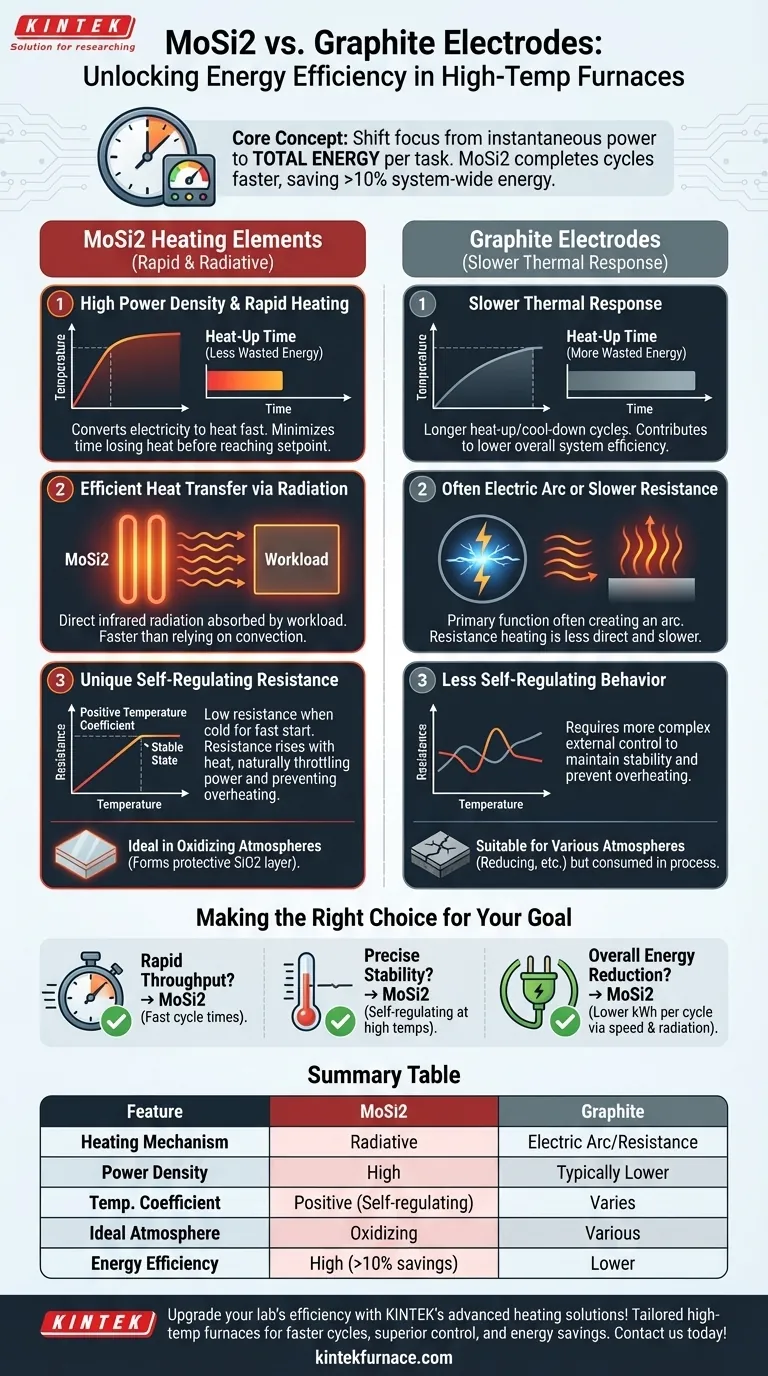

At its core, the energy efficiency of Molybdenum Disilicide (MoSi2) heating elements over graphite electrodes stems from their ability to heat up extremely quickly and transfer that heat directly to the workload via radiation. This rapid performance minimizes wasted energy during heat-up cycles, resulting in lower overall power consumption for a completed process.

The key to understanding MoSi2's efficiency is to shift focus from instantaneous power draw to total energy consumed per task. Its high power density and radiative properties enable it to complete heating cycles faster, leading to system-wide energy savings of over 10% compared to alternatives.

The Principles of MoSi2 Heating Efficiency

To truly grasp the advantage, we must look beyond a single material property and examine how the element functions within a complete heating system. The efficiency is a result of multiple synergistic factors.

High Power Density and Rapid Heating

MoSi2 elements can handle very high electrical loads, a characteristic known as high power density.

This allows them to convert electricity into heat at an exceptional rate, raising the furnace temperature to the desired setpoint much faster than many alternatives.

Reducing the time-to-temperature directly cuts down on the period during which the furnace is losing heat to the surroundings without performing its primary function. This reduction in "wasted time" is a primary source of energy savings.

Efficient Heat Transfer via Radiation

At their high operating temperatures, MoSi2 elements glow intensely. The majority of their energy is transferred as infrared radiation.

Radiant heat travels in a straight line and is absorbed directly by the materials inside the furnace. This method is far more direct and efficient for heating the workload compared to relying solely on slower, less-targeted convection currents.

Unique Electrical Resistance Behavior

Unlike many materials, MoSi2 has a strong positive temperature coefficient. This means its electrical resistance increases significantly as it gets hotter.

This behavior is inherently self-regulating. When cold, the element has low resistance, allowing it to draw high power for rapid initial heating. As it approaches its target temperature, the rising resistance naturally throttles the power draw, leading to a stable state with minimal need for complex external control. This prevents overheating and stabilizes energy consumption.

Understanding the Trade-offs and Context

No single technology is universally superior. The choice between MoSi2 and graphite depends entirely on the application, atmosphere, and operational goals.

MoSi2's Ideal Operating Environment

MoSi2 elements excel in air or oxidizing atmospheres. At high temperatures, they form a protective, self-healing layer of quartz glass (SiO2) on their surface, which prevents further oxidation and ensures a long service life.

However, they are not suitable for all environments. Reducing atmospheres can damage this protective layer, and the material itself is brittle at room temperature, requiring careful handling during installation.

Graphite's Role and Limitations

Graphite electrodes are staples in applications like electric arc furnaces for steelmaking, where they are consumed as part of the process. Their primary function is often to create an electric arc, a fundamentally different heating mechanism than the resistance heating of MoSi2.

In resistance heating applications, graphite can be effective but typically has a slower thermal response. This means longer heat-up and cool-down cycles, which contributes to lower overall system efficiency compared to the rapid cycling enabled by MoSi2.

Making the Right Choice for Your Goal

Selecting the correct heating element requires aligning the technology's strengths with your primary operational objective.

- If your primary focus is rapid throughput: MoSi2 is the superior choice due to its high power density, which drastically shortens process cycle times.

- If your primary focus is precise temperature stability: MoSi2's self-regulating resistance provides excellent thermal stability at high temperatures with simplified power control.

- If your primary focus is overall energy reduction: MoSi2's ability to shorten heat-up phases and transfer energy efficiently via radiation results in lower kilowatt-hour consumption per cycle.

By understanding these core principles, you can select a heating technology based not on a single specification, but on its total impact on your operational efficiency.

Summary Table:

| Feature | MoSi2 Heating Elements | Graphite Electrodes |

|---|---|---|

| Heating Mechanism | Radiative heat transfer | Often electric arc or slower resistance heating |

| Power Density | High, enabling rapid heat-up | Typically lower, leading to slower cycles |

| Temperature Coefficient | Positive (self-regulating) | Varies, less self-regulating |

| Ideal Atmosphere | Oxidizing (e.g., air) | Suitable for various, including reducing |

| Energy Efficiency | High, with over 10% savings in total energy per cycle | Lower due to longer heat-up times |

| Key Applications | High-temperature furnaces for rapid throughput and stability | Electric arc furnaces, steelmaking |

Upgrade your laboratory's efficiency with KINTEK's advanced heating solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored high-temperature furnace systems, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure precise alignment with your unique experimental needs, helping you achieve faster heating cycles, superior temperature control, and significant energy savings. Contact us today to discuss how our MoSi2-based solutions can optimize your processes and reduce operational costs!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- Why are silicon carbide heating elements essential in high-temperature industries? Unlock Reliable, Extreme Heat Solutions

- Why is silicon carbide resistant to chemical reactions in industrial furnaces? Unlock Durable High-Temp Solutions

- What is the maximum temperature silicon carbide heating elements can withstand? Key Factors for Longevity and Performance

- What makes SIC heating elements superior for high-temperature applications? Unlock Efficiency and Durability

- Why are SIC heating elements resistant to chemical corrosion? Discover the Self-Protecting Mechanism