At its core, an induction furnace melts conductive materials like metal without using any flames or direct contact. It operates on the principle of electromagnetic induction, where a powerful, fluctuating magnetic field generated by an electrical coil induces strong internal currents within the metal itself. The metal's natural resistance to these currents generates intense heat, causing it to melt from the inside out.

The fundamental advantage of an induction furnace is its ability to turn the metal itself into the heat source. This contactless, precise, and rapid heating offers superior control and efficiency compared to traditional furnaces that heat material externally.

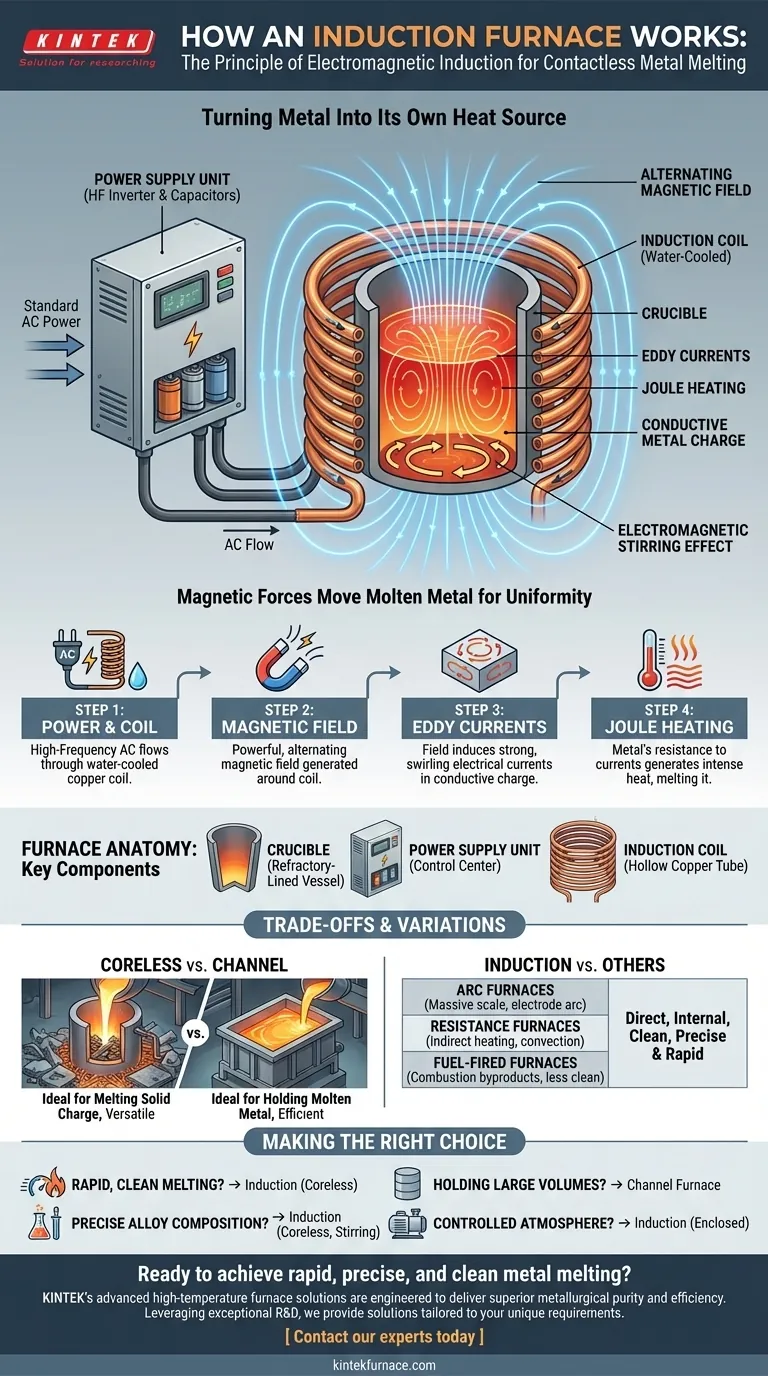

The Principle: Turning Metal Into Its Own Heater

Understanding how an induction furnace works is about understanding a controlled, high-powered application of electromagnetic physics. The process is clean, contained, and remarkably fast.

The Role of the Induction Coil

The process begins with the induction coil, which is typically a hollow copper tube. A powerful, high-frequency alternating current (AC) is passed through this coil. To prevent the coil itself from overheating, it is actively cooled with circulating water.

Generating the Magnetic Field

As the AC flows through the coil, it generates a strong and rapidly alternating magnetic field in the space within and around the coil. The frequency of this current can range from 500 to 2000 Hz or higher, dictating the characteristics of the magnetic field.

Inducing Eddy Currents

When a conductive material, known as the charge, is placed inside the crucible within the coil, it is penetrated by this magnetic field. The fluctuating field induces powerful, swirling electrical currents within the charge. These are known as eddy currents.

The Power of Resistance (Joule Heating)

The charge material has inherent electrical resistance. As the strong eddy currents flow against this resistance, they generate tremendous friction and heat. This effect, known as Joule heating, is what raises the temperature of the charge to its melting point and beyond.

Think of it as a transformer: the furnace's coil is the primary winding, and the metal charge acts as a single-turn secondary winding that is short-circuited on itself.

Anatomy of a Coreless Induction Furnace

The coreless design is the most common type of induction furnace, valued for its versatility in melting everything from iron and steel to copper and aluminum alloys.

The Crucible

This is the refractory-lined vessel that holds the charge. It must be made from a material that can withstand extreme temperatures and is non-conductive, ensuring the magnetic field passes through it to act directly on the metal inside.

The Power Supply Unit

This is the control center of the furnace. It takes standard utility power and converts it into the high-frequency, high-current power required by the coil. It consists of transformers, a high-frequency inverter, and a bank of capacitors to optimize the electrical circuit.

The Electromagnetic Stirring Effect

A significant secondary benefit of the induction process is a natural stirring action. The same magnetic forces that induce eddy currents also create forces that move the molten metal. This constant circulation ensures a uniform temperature and helps evenly mix alloying elements, resulting in a higher quality, homogenous final product.

Understanding the Trade-offs and Variations

While powerful, induction heating isn't a universal solution. Understanding its different forms and limitations is key to using it effectively.

Coreless vs. Channel Furnaces

A coreless furnace, as described above, is ideal for melting solid charge material and for applications requiring frequent changes in alloys.

A channel furnace operates more like a true transformer, with an iron core linking the primary coil to a closed loop or "channel" of molten metal. These furnaces are extremely efficient at holding large volumes of metal at a constant temperature but are not well-suited for melting from a cold state. They are typically used as holding furnaces in large foundries.

Induction vs. Other Heating Methods

- Arc Furnaces use a high-power electric arc between electrodes to melt the charge. They are used for massive-scale production (e.g., steel mini-mills) and generate heat differently.

- Resistance Furnaces (like a box or tube furnace) use heating elements to heat a chamber, which then transfers heat to the material via convection and radiation. This is an indirect and often slower process compared to the direct internal heating of induction.

- Fuel-Fired Furnaces use the combustion of gas or oil. This introduces combustion byproducts, offering less chemical purity than the clean melt of an induction furnace.

Key Limitation: Conductive Materials

The primary principle of induction heating relies on the charge material being electrically conductive. It cannot directly heat non-conductive materials like ceramics. To overcome this, a conductive crucible (e.g., graphite) can be used, which heats up via induction and then transfers its heat to the non-conductive material inside.

Making the Right Choice for Your Goal

Selecting a furnace technology depends entirely on the metallurgical objective.

- If your primary focus is rapid, clean, and controlled melting: An induction furnace is ideal due to its fast heating cycles and minimal contamination.

- If your primary focus is achieving a precise alloy composition: The natural stirring action of a coreless induction furnace ensures excellent metallurgical homogeneity.

- If your primary focus is holding large volumes of molten metal efficiently: A channel-type induction furnace offers superior energy efficiency for maintaining temperature over long periods.

- If you need to melt in a controlled atmosphere or vacuum: The compact and enclosed nature of an induction furnace makes it easily adaptable for these specialized applications.

Ultimately, choosing an induction furnace is a decision for precision, speed, and metallurgical purity in your melting operations.

Summary Table:

| Key Component / Process | Function |

|---|---|

| Induction Coil | Carries high-frequency AC to generate a powerful, alternating magnetic field. |

| Magnetic Field | Penetrates the conductive metal charge placed inside the crucible. |

| Eddy Currents | Induced swirling electrical currents within the metal charge. |

| Joule Heating | Heat generated from the metal's resistance to eddy currents, melting it from the inside out. |

| Electromagnetic Stirring | A natural side effect that ensures uniform temperature and alloy mixing in the molten metal. |

Ready to achieve rapid, precise, and clean metal melting?

KINTEK's advanced high-temperature furnace solutions, including our customizable induction furnace systems, are engineered to deliver superior metallurgical purity and efficiency. Leveraging our exceptional R&D and in-house manufacturing capabilities, we provide solutions tailored to your unique operational requirements, whether you're melting ferrous or non-ferrous alloys.

Contact our experts today to discuss how our technology can enhance your melting process with precise control, rapid heating cycles, and minimal contamination.

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is vacuum induction melting technology and why is it important? Achieve High-Purity Metals for Critical Applications

- How does the Vacuum Induction Melting (VIM) process work? Achieve Superior Metal Purity and Control

- How has vacuum smelting impacted the development of superalloys? Unlock Higher Strength and Purity

- What are some common applications of vacuum induction melting and casting (VIM&C)? Essential for Aerospace, Medical, and Nuclear Industries

- What are the core functions of the High Vacuum Induction Melting (VIM) furnace? Optimize DD5 Superalloy Purification