At its core, a silicon carbide heating rod works by converting electrical energy into thermal energy. When an electric current is passed through the rod, the material's high natural resistance causes it to heat up intensely. This principle, known as resistance heating, allows silicon carbide elements to reliably achieve extremely high operational temperatures up to 1450°C (2642°F).

The key to the silicon carbide heating rod is not just that it gets hot. Its true value lies in a unique combination of extreme temperature tolerance, exceptional chemical stability, and structural integrity, making it a superior choice for demanding industrial heating applications where other materials would quickly degrade or fail.

The Fundamental Principle: Resistance Heating

A silicon carbide (SiC) rod operates on one of the most direct principles of physics: converting electricity into heat. However, the specific properties of the material are what make it so effective.

From Electricity to Heat

The fundamental process is Joule heating. When an electric current flows through any material with resistance, a portion of the electrical energy is converted into heat. The high resistivity of silicon carbide makes this energy conversion incredibly efficient.

The Role of Material Purity

These heating elements are not made from simple SiC powder. They are typically formed from high-purity, recrystallized silicon carbide, which is extruded into a rod or tube shape.

This mixture is then fired at temperatures exceeding 2500°C (4530°F). This extreme process creates strong, uniform bonds between the SiC grains, resulting in a dense, highly stable element with consistent electrical properties.

A Self-Regulating Characteristic

A key operational feature is that the resistivity of silicon carbide changes with temperature. As the rod heats up, its resistance profile shifts. This behavior helps the element automatically adjust its power draw, contributing to a more stable and consistent heating effect once the target temperature is reached.

Why Silicon Carbide is the Material of Choice

Many materials have electrical resistance, but few can perform under the conditions that silicon carbide excels in. Its selection is based on a collection of superior properties.

Extreme Temperature Tolerance

The single most important characteristic of a SiC element is its ability to operate continuously at very high temperatures. With a maximum operating temperature of 1450°C, it is perfectly suited for furnaces and kilns used in glass manufacturing, ceramics firing, and metal heat treating.

Exceptional Chemical Durability

SiC exhibits strong anti-oxidation properties and resistance to acids. This chemical stability means it does not easily corrode or degrade, even in harsh industrial atmospheres. This directly translates to a longer and more predictable service life compared to many metallic heating elements.

High Thermal Conductivity

Despite being a ceramic, silicon carbide has good thermal conductivity. This property ensures that the heat generated within the rod is transferred efficiently and uniformly to the surrounding environment, enabling rapid heating cycles and maintaining stable temperatures within a furnace.

Understanding the Practical Implications

While SiC is a robust material, understanding its real-world behavior is critical for proper implementation and longevity.

Gradual Aging

Over its service life, a silicon carbide element will slowly increase in electrical resistance. This is a natural aging process caused by oxidation. To compensate and maintain constant power output (and thus heat), the voltage supplied to the element must be gradually increased over time. This is a primary consideration for the power supply and control system.

Mechanical Brittleness

Like most ceramics, SiC elements are hard but brittle. They are susceptible to damage from mechanical shock or impact. Careful handling is absolutely essential during installation, maintenance, and operation to prevent fractures.

Atmospheric Sensitivity

While highly resistant, the lifespan of a SiC element can be affected by certain atmospheres. The presence of water vapor, alkali, or certain metals at high temperatures can accelerate the aging process. Operating in a clean, controlled atmosphere will maximize the element's service life.

Making the Right Choice for Your Application

Selecting a SiC heating element is an engineering decision based on your specific process requirements.

- If your primary focus is reaching extreme temperatures (above 1200°C): SiC is one of the most reliable and effective choices due to its high operational limit and stability.

- If your primary focus is process consistency in a harsh environment: The chemical inertness and predictable aging of SiC provide consistent thermal performance where metallic elements would corrode.

- If your primary focus is long-term value and reduced downtime: The long service life of SiC, when properly managed with a variable voltage supply, often results in a lower total cost of ownership.

By understanding these principles, you can confidently leverage silicon carbide's unique properties for robust and efficient high-temperature processes.

Summary Table:

| Aspect | Details |

|---|---|

| Working Principle | Converts electrical energy to heat via resistance (Joule heating) |

| Max Temperature | Up to 1450°C (2642°F) |

| Key Properties | High temperature tolerance, chemical durability, thermal conductivity |

| Applications | Glass, ceramics, metal heat treating in industrial furnaces |

| Lifespan Considerations | Gradual resistance increase with age; requires voltage adjustment |

Optimize your high-temperature processes with KINTEK's advanced solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable silicon carbide heating elements and custom furnace systems like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capability ensures precise fit for your unique experimental needs, enhancing efficiency and durability. Contact us today to discuss how we can elevate your industrial heating applications!

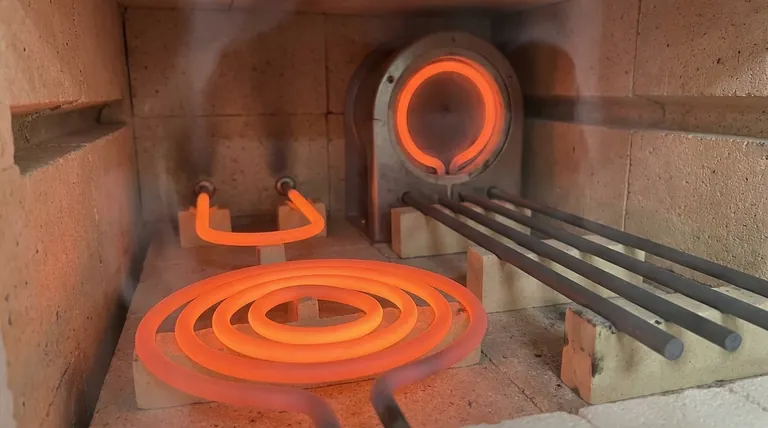

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- What makes SIC heating elements superior for high-temperature applications? Unlock Efficiency and Durability

- What makes silicon carbide heating elements resistant to chemical corrosion? Discover the Protective Oxide Layer

- What are the properties and applications of silicon carbide (SiC)? Unlock High-Temperature Performance

- Why is silicon carbide resistant to chemical reactions in industrial furnaces? Unlock Durable High-Temp Solutions

- What are the advantages of using high purity green silicon carbide powder in heating elements? Boost Efficiency and Lifespan