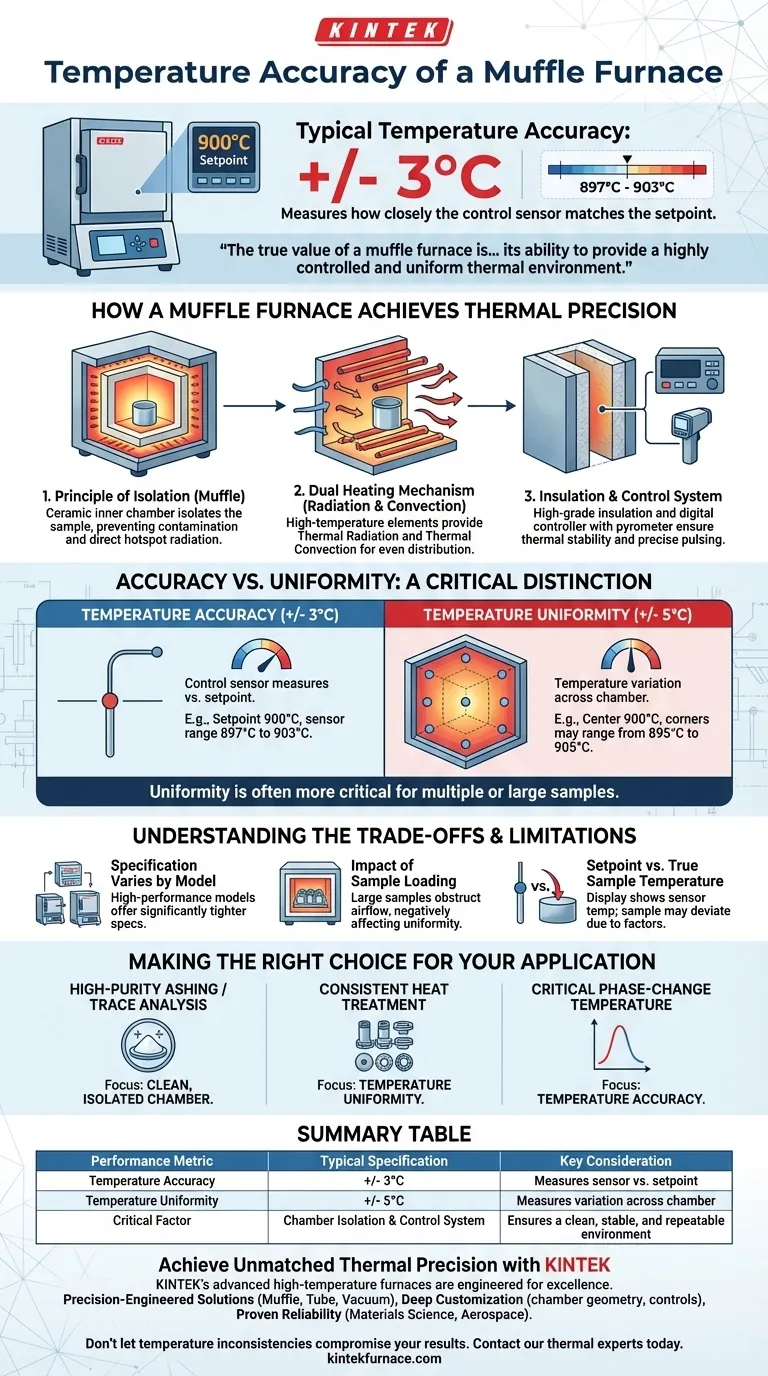

In a standard laboratory setting, a muffle furnace typically achieves a temperature accuracy of +/- 3°C. This figure represents how closely the measured temperature at the control sensor matches the desired setpoint. However, this number is only one part of the furnace's thermal performance, which is defined by its ability to create a clean, stable, and uniform heating environment.

The true value of a muffle furnace is not just its accuracy at a single point, but its ability to provide a highly controlled and uniform thermal environment. For precise work, understanding the distinction between temperature accuracy and temperature uniformity is more critical than focusing on a single specification.

How a Muffle Furnace Achieves Thermal Precision

The design of a muffle furnace is entirely focused on creating a controlled and isolated heating zone. This architecture is what allows for its high level of accuracy and repeatability.

The Principle of Isolation

The defining characteristic of a muffle furnace is the muffle itself—an inner chamber, often made of a ceramic material like siliminite, that isolates the sample.

This design separates the material being heated from the heating elements. It ensures there is no contamination from combustion byproducts (in fuel-fired models) or direct radiation hotspots from electric coils, creating a clean and stable environment.

The Dual Heating Mechanism

Modern electric muffle furnaces use high-temperature heating elements, such as nichrome or silicon carbide wires, that line the chamber walls.

These elements heat the chamber using two principles simultaneously: thermal radiation, which transfers heat directly to the sample, and thermal convection, which heats the air and circulates it to ensure even temperature distribution.

The Role of Insulation and Control

Thick layers of high-grade insulation surround the muffle, minimizing heat loss to the outside environment. This thermal stability is essential for the control system to work effectively.

A digital controller continuously monitors the chamber's temperature via a sensor (pyrometer) and pulses power to the heating elements to hold the temperature precisely at the user's setpoint.

Accuracy vs. Uniformity: A Critical Distinction

While often used interchangeably, accuracy and uniformity describe two different aspects of a furnace's performance. Understanding the difference is crucial for achieving reliable results.

Temperature Accuracy (+/- 3°C)

Temperature accuracy measures how close the temperature at the control sensor is to the setpoint on the digital display.

If you set your furnace to 900°C, an accuracy of +/- 3°C means the temperature at the sensor's location will be stable between 897°C and 903°C. This is a measure of the control system's reliability.

Temperature Uniformity (+/- 5°C)

Temperature uniformity describes the maximum temperature variation between different points inside the heating chamber.

A uniformity rating of +/- 5°C means that if the center is at 900°C, some corners might be as low as 895°C and other areas as high as 905°C. For processing larger samples or multiple items at once, uniformity is often the more important metric.

Understanding the Trade-offs and Limitations

While highly reliable, a muffle furnace's performance is subject to physical constraints and proper use.

Specification Varies by Model

The +/- 3°C figure is a common specification for general-purpose lab furnaces. High-performance models designed for materials science, aerospace, or advanced ceramics may offer significantly tighter accuracy and uniformity.

The Impact of Sample Loading

Placing a very large sample or a fully loaded tray of small items inside the chamber can obstruct airflow. This disruption to thermal convection can negatively impact temperature uniformity across the load.

Setpoint vs. True Sample Temperature

The controller's display shows the temperature at the sensor's location, not necessarily the exact temperature of your sample. Factors like sample density, placement within the chamber, and radiant heat "shadows" can cause minor deviations.

Making the Right Choice for Your Application

Use these guidelines to determine which thermal property is most important for your specific process.

- If your primary focus is high-purity ashing or trace metal analysis: The furnace's clean, isolated chamber is the most critical feature, preventing any contamination of your sample.

- If your primary focus is consistent heat treatment of multiple parts: Temperature uniformity is your most important metric to ensure every part experiences the same thermal conditions.

- If your primary focus is hitting a critical phase-change temperature: Temperature accuracy is paramount, and you should rely on a furnace with a high-quality digital controller.

By understanding how a muffle furnace works, you can leverage its unique design to achieve highly accurate, stable, and repeatable results in your work.

Summary Table:

| Performance Metric | Typical Specification | Key Consideration |

|---|---|---|

| Temperature Accuracy | +/- 3°C | Measures how closely the control sensor matches the setpoint. |

| Temperature Uniformity | +/- 5°C | Describes the temperature variation across the chamber. |

| Critical Factor | Chamber Isolation & Control System | Ensures a clean, stable, and repeatable thermal environment. |

Achieve Unmatched Thermal Precision with KINTEK

Does your research demand exact temperature control and superior uniformity? KINTEK's advanced high-temperature furnaces are engineered for excellence. Leveraging our exceptional in-house R&D and manufacturing, we provide:

- Precision-Engineered Solutions: Our Muffle Furnaces, Tube Furnaces, and Vacuum & Atmosphere Furnaces are designed for maximum accuracy and uniformity.

- Deep Customization: We tailor every aspect of the furnace—from chamber geometry to control systems—to meet your unique experimental requirements.

- Proven Reliability: Ideal for applications in materials science, aerospace, and advanced ceramics where thermal performance is critical.

Don't let temperature inconsistencies compromise your results. Contact our thermal experts today to discuss how a KINTEK furnace can be customized for your specific needs.

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites

- What key step does a Muffle Furnace perform in the determination of mineral content in Tenebrio molitor larvae?

- What is the core function of a muffle furnace in CuO nanoparticle synthesis? Achieve Precision Calcination

- How does the use of a 100-mesh sieve contribute to the performance consistency of magnetic chitosan carbon?