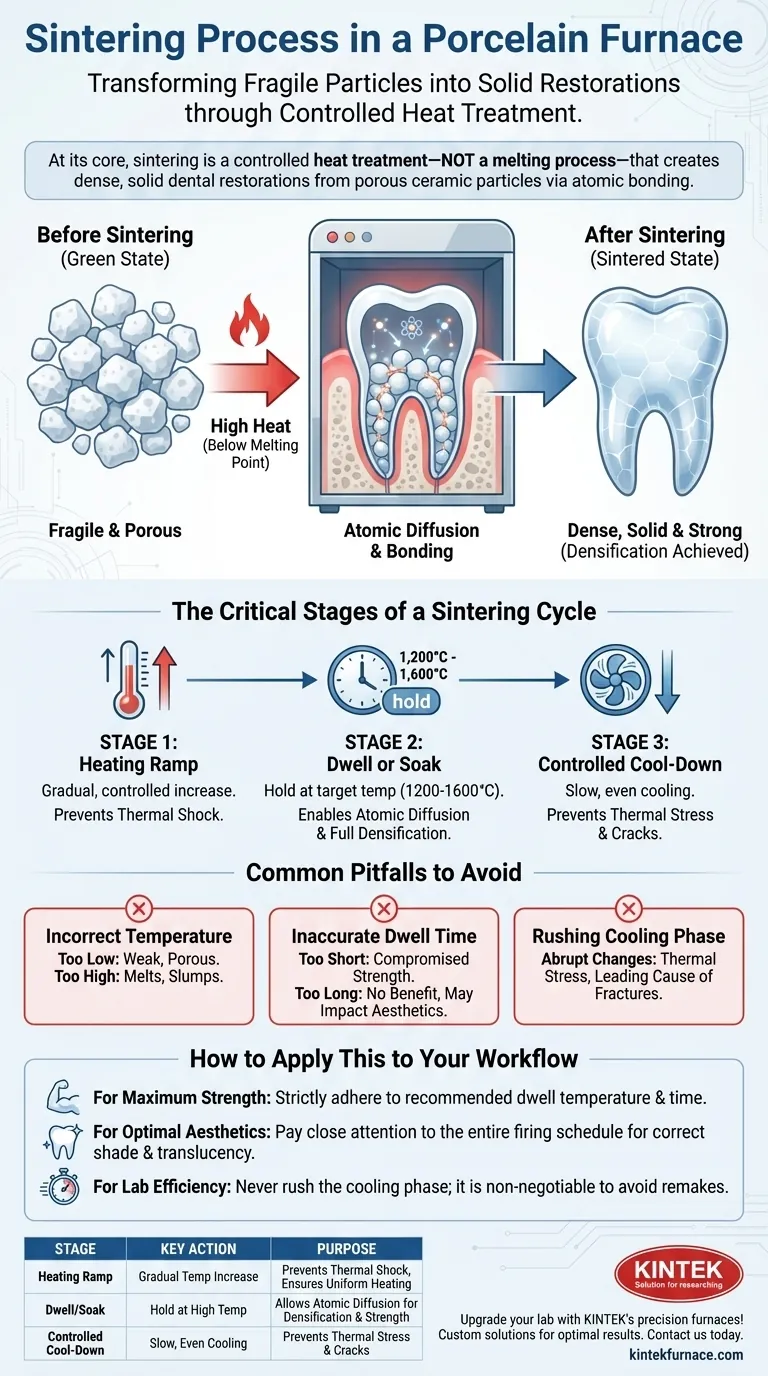

At its core, sintering is a controlled heat treatment process within a porcelain furnace that transforms fragile, porous ceramic particles into a dense, solid, and strong dental restoration. It works by heating the material to a very high temperature—just below its melting point—which causes the individual particles to fuse together, eliminating the voids between them and creating a solid mass.

Sintering is not a melting process. It is a more subtle act of atomic bonding that uses high heat to force solid particles to merge, achieving the final strength, density, and aesthetic properties required for a successful dental prosthetic.

The Goal: From a Fragile State to a Solid Restoration

Sintering is the critical transition that gives a dental ceramic its final, functional characteristics. The process is entirely dependent on precise thermal management.

The Principle of Particle Bonding

Before sintering, a milled or pressed restoration (often called its "green state") is composed of ceramic particles loosely held together. It is chalky and extremely fragile.

During sintering, the intense heat energizes the atoms within these particles. This energy allows atoms to migrate across the boundaries where particles touch, effectively building bridges between them. This process, known as atomic diffusion, merges the particles into a unified, polycrystalline structure without ever becoming liquid.

Achieving Full Densification

The primary objective of sintering is densification. As the particles fuse together, the microscopic pores and voids between them are gradually eliminated.

This reduction in porosity is what gives the final restoration its strength, durability, and translucency. A poorly sintered piece will remain porous, making it weak, prone to fracture, and aesthetically inferior.

The Critical Stages of a Sintering Cycle

A successful sintering cycle is a carefully programmed sequence of heating and cooling. Modern porcelain furnaces manage these stages with extreme precision.

Stage 1: The Heating Ramp

The furnace temperature is increased gradually and steadily. A controlled ramp rate is crucial to ensure the entire restoration heats uniformly, preventing thermal shock that could cause cracks before the actual sintering even begins.

Stage 2: The Dwell or Soak

Once the target temperature is reached—often between 1,200°C and 1,600°C (2,200°F to 2,900°F) depending on the material—it is held constant for a specific period. This "dwell time" is when the majority of atomic diffusion and densification occurs.

Stage 3: The Controlled Cool-Down

This is arguably as critical as the heating stage. The restoration must be cooled slowly and evenly to prevent the build-up of internal thermal stress. Cooling too rapidly will cause the exterior to shrink faster than the interior, leading to cracks or complete fracture.

Common Pitfalls to Avoid

The success of a restoration is entirely dependent on the accuracy of the sintering cycle. Deviations from the manufacturer's prescribed parameters are a primary source of failure.

Incorrect Temperature Settings

If the dwell temperature is too low, sintering will be incomplete, resulting in a weak and porous restoration. If the temperature is too high, the material can begin to melt, causing it to slump, lose anatomical detail, or become glassy and brittle.

Inaccurate Dwell Times

A dwell time that is too short will not allow for full densification, compromising the material's strength. Conversely, an excessively long dwell time typically offers no additional benefit and can sometimes negatively impact the material's aesthetic properties.

Rushing the Cooling Phase

The temptation to remove a restoration from the furnace early to save time is a significant risk. Abrupt changes in temperature during the cooling phase are the leading cause of post-sintering fractures.

How to Apply This to Your Workflow

Understanding these principles allows you to troubleshoot issues and ensure consistent, high-quality outcomes from your porcelain furnace.

- If your primary focus is maximum strength and durability: Strictly adhere to the manufacturer's recommended dwell temperature and time to guarantee complete densification.

- If your primary focus is optimal aesthetics: Pay close attention to the firing schedule, as the final translucency and shade are directly linked to a correct and complete sintering cycle.

- If your primary focus is lab efficiency: Recognize that the cooling phase is non-negotiable and cannot be rushed without significantly increasing the risk of remakes.

Mastering the principles of sintering transforms the porcelain furnace from a simple oven into a precision instrument for creating predictable, high-quality restorations.

Summary Table:

| Stage | Key Action | Purpose |

|---|---|---|

| Heating Ramp | Gradual temperature increase | Prevents thermal shock and ensures uniform heating |

| Dwell/Soak | Hold at high temperature (1200-1600°C) | Allows atomic diffusion for densification and strength |

| Controlled Cool-Down | Slow, even cooling | Prevents thermal stress and cracks in the restoration |

Upgrade your dental lab with KINTEK's precision high-temperature furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide advanced solutions like Muffle, Tube, and Vacuum Furnaces, tailored to your unique sintering needs. Our deep customization ensures optimal strength, aesthetics, and efficiency for your restorations. Contact us today to discuss how we can enhance your workflow and deliver reliable results!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations

- What are the recommended maintenance practices for dental furnaces? Ensure Precision and Longevity for Your Lab

- What aspects of a dental restoration are directly impacted by the choice of a dental sintering furnace? Ensure Fit, Strength & Longevity

- What is the working principle of a dental furnace? Mastering Precision Sintering & Firing for Crowns

- How often should dental furnaces be calibrated? Ensure Precision for Perfect Restorations