In academic and scientific research, porcelain furnaces and their modern equivalents are significant because they provide the precisely controlled, high-temperature environments necessary for creating and testing new materials. They are the instruments that allow researchers to manipulate matter at a fundamental level, turning theoretical concepts into tangible substances with novel properties. This capability is the bedrock of modern materials science.

The true significance of these furnaces is not the equipment itself, but their function as a crucible for innovation. They enable the precise thermal processing required to synthesize new materials, understand their fundamental behaviors, and ultimately drive advancements across nearly every field of technology.

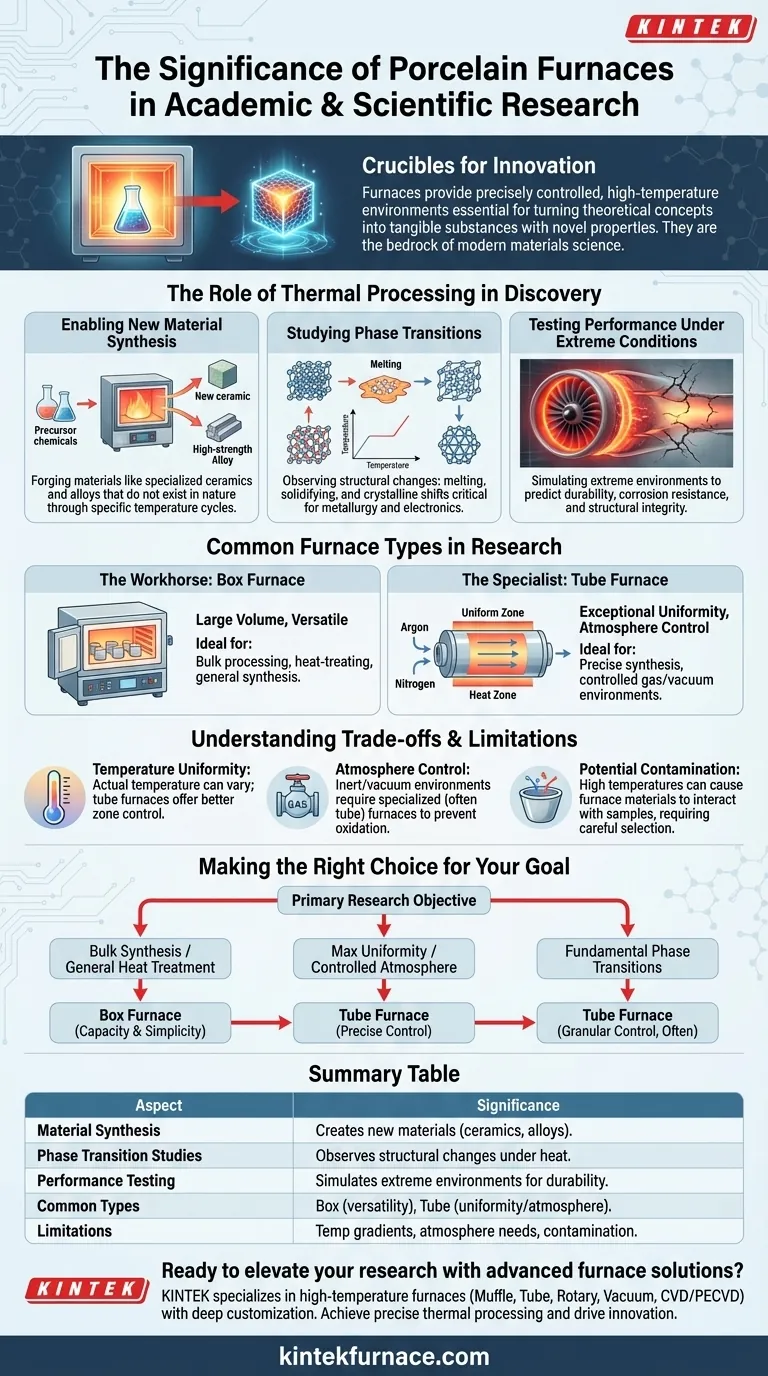

The Role of Thermal Processing in Discovery

The ability to precisely apply and control heat is fundamental to materials science. A furnace is not just an oven; it is a carefully calibrated instrument for directing the formation and transformation of matter.

Enabling New Material Synthesis

Many advanced materials, from specialized ceramics to high-strength alloys, do not exist in nature. They must be synthesized by subjecting precursor chemicals to specific temperature cycles. Furnaces provide the repeatable, high-temperature conditions needed to forge these new materials.

Studying Phase Transitions

Heating and cooling cause materials to change their internal structure, a phenomenon known as a phase transition. Researchers use furnaces to carefully observe these changes, understanding exactly when and how a material might melt, solidify, or shift from one crystalline form to another. This knowledge is critical for applications from metallurgy to electronics.

Testing Performance Under Extreme Conditions

To be useful in the real world, materials must be reliable. Furnaces are used to simulate extreme operating environments, testing a material's durability, resistance to corrosion, and structural integrity at high temperatures. This helps predict and improve material performance in applications like jet engines or power plants.

Common Furnace Types in Research

While "porcelain furnace" is a common term, modern research labs typically use specific types of high-temperature furnaces, most often box and tube furnaces. Both utilize advanced ceramic components (like porcelain or alumina) for insulation and containment.

The Workhorse: The Box Furnace

A box furnace is characterized by a rectangular chamber, providing a relatively large volume for heating. This design is highly versatile, making it ideal for processing multiple samples at once, heat-treating larger components, or conducting general-purpose synthesis.

The Specialist: The Tube Furnace

A tube furnace features a cylindrical chamber, typically made of quartz or a high-purity ceramic. This design excels at providing exceptional temperature uniformity along its length and allows for tightly controlled atmospheric conditions by flowing specific gases (like argon or nitrogen) through the tube.

Understanding the Trade-offs and Limitations

Choosing and using a furnace requires a clear understanding of its limitations. The success of an experiment often depends on controlling variables that go beyond just the maximum temperature.

Temperature Uniformity and Control

The advertised temperature is often for the center of the furnace. The actual temperature can vary in different parts of the chamber. For sensitive experiments, understanding this temperature gradient is critical, and tube furnaces generally offer superior uniformity over a specific zone.

The Importance of Atmosphere

A standard furnace heats a sample in ambient air. However, oxygen in the air can react with and contaminate many materials at high temperatures. Conducting experiments in a controlled, inert atmosphere or a vacuum requires a more complex and specialized furnace, typically a tube furnace.

Potential for Sample Contamination

At very high temperatures, even the inert ceramic materials of the furnace chamber can subtly interact with or release trace elements into the sample. For ultra-high-purity research, this is a significant consideration that requires careful material selection for both the furnace lining and sample holders (crucibles).

Making the Right Choice for Your Goal

The right furnace is the one that best matches your specific experimental needs. Your decision should be guided by your primary research objective.

- If your primary focus is bulk synthesis or general heat treatment: A box furnace provides the capacity and operational simplicity for processing larger or multiple samples effectively.

- If your primary focus is achieving maximum temperature uniformity or working with a controlled atmosphere: A tube furnace offers the precise environmental control necessary for sensitive material synthesis and analysis.

- If your primary focus is studying fundamental phase transitions: Your choice depends on sample size and atmospheric requirements, but a tube furnace often provides more granular control for academic investigation.

Ultimately, these furnaces are the essential tools that bridge the gap between theoretical knowledge and real-world material innovation.

Summary Table:

| Aspect | Significance |

|---|---|

| Material Synthesis | Enables creation of new materials like ceramics and alloys through controlled heating. |

| Phase Transition Studies | Allows observation of structural changes in materials under precise thermal conditions. |

| Performance Testing | Simulates extreme environments to assess durability and reliability of materials. |

| Common Types | Box furnaces for versatility; tube furnaces for uniformity and atmosphere control. |

| Limitations | Includes temperature gradients, atmospheric control needs, and potential contamination risks. |

Ready to elevate your research with advanced furnace solutions? KINTEK specializes in high-temperature furnaces tailored for academic and scientific labs. Leveraging exceptional R&D and in-house manufacturing, we offer Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, with deep customization to meet your unique experimental needs. Achieve precise thermal processing and drive innovation—contact us today to discuss how we can support your projects!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision