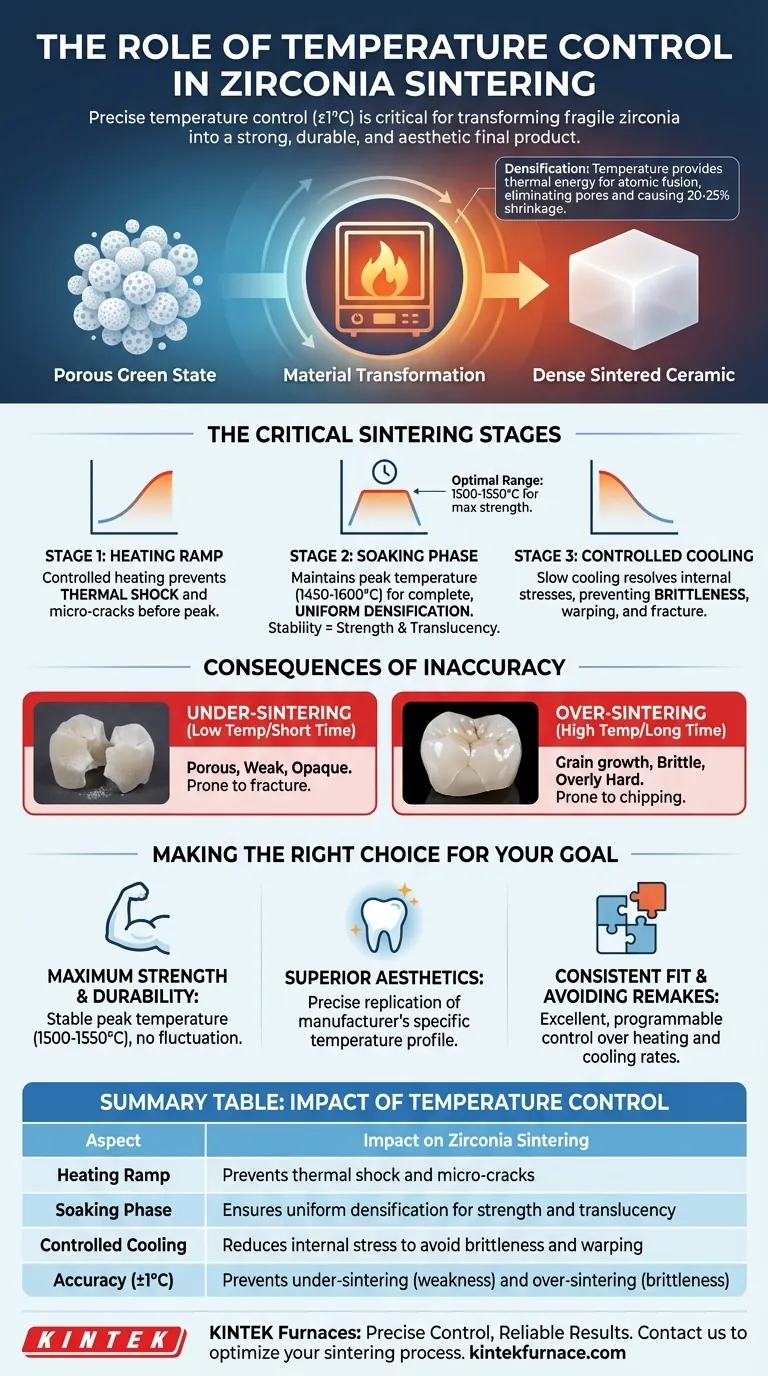

In the sintering of zirconia, precise temperature control is the single most critical factor dictating the final physical and aesthetic properties of the restoration. Modern furnaces that maintain temperature accuracy within ±1°C are not a luxury; they are essential for transforming a fragile, milled "green state" crown into a strong, durable, and aesthetically pleasing final product.

Sintering is not simply a heating process, but a material transformation. The core purpose of temperature control is to precisely manage this transformation, as even minor deviations can lead to unpredictable material properties and, ultimately, clinical failures like fractures, discoloration, or poor fit.

How Temperature Governs the Sintering Process

Sintering is a process of densification. It converts a porous, milled zirconia structure into a dense, solid ceramic by applying heat just below its melting point.

The Transformation at the Atomic Level

During sintering, individual zirconia particles fuse together. This process eliminates the pores between them, causing the material to shrink significantly and increase in density.

Temperature provides the thermal energy required for atoms to move across particle boundaries, enabling this fusion. The rate and uniformity of this process are directly controlled by the heat applied.

Managing the Shrinkage Factor

Zirconia can shrink by 20-25% during sintering. Inaccurate or uneven temperature control causes non-uniform shrinkage, which leads to warping and distortion.

This is a primary cause of poor marginal fit, requiring time-consuming adjustments or complete remakes. Precise temperature management ensures the entire restoration shrinks predictably and evenly.

The Critical Role of Each Temperature Stage

A successful sintering cycle is a carefully programmed sequence of heating and cooling. Control is vital at every stage.

Stage 1: Heating Ramp

The furnace slowly and steadily raises the temperature to the target peak. A controlled ramp rate is crucial to prevent thermal shock, which can introduce micro-cracks into the material before it even reaches peak temperature.

Stage 2: The Soaking Phase

The furnace holds the zirconia at a specific peak temperature, typically between 1450°C and 1600°C, for a set duration (e.g., 30 minutes to 2 hours). This "soak" allows heat to penetrate the restoration uniformly, ensuring complete and even densification.

The stability of the temperature during this phase has the biggest impact on the final strength and translucency. Research indicates that a peak temperature around 1500-1550°C often yields the maximum strength for many zirconia types.

Stage 3: Controlled Cooling

Just as important as heating, the cooling phase must be gradual. Slow, controlled cooling allows internal stresses within the ceramic to resolve.

Rapid cooling can lock in stress, making the restoration brittle and prone to fracture later on. It can also contribute to warping.

Understanding the Trade-offs: The Consequences of Inaccuracy

Deviating from the ideal temperature profile has direct, negative consequences on the quality of the final restoration.

The Risk of Under-Sintering

Firing at a temperature that is too low or for too short a time results in incomplete sintering. The final restoration will be porous, weak, and opaque, making it prone to fracture and aesthetically unacceptable.

The Danger of Over-Sintering

Firing at a temperature that is too high or for too long can cause grain growth within the material. This makes the restoration overly hard but also more brittle, increasing its susceptibility to chipping or cracking under clinical loads.

The Impact of Temperature Fluctuation

An unstable furnace that cannot hold a steady temperature introduces unpredictability. These fluctuations affect the final color, translucency, and strength, leading to inconsistent results from one cycle to the next, even when using the same material and program.

Making the Right Choice for Your Goal

Achieving predictable results requires matching your furnace's capabilities to your clinical priorities.

- If your primary focus is maximum strength and durability: Ensure your furnace can hold a stable peak temperature in the optimal 1500-1550°C range with virtually no fluctuation.

- If your primary focus is superior aesthetics (color and translucency): Prioritize a furnace renowned for its ability to replicate a zirconia manufacturer's specific temperature profile with absolute precision.

- If your primary focus is consistent fit and avoiding remakes: Choose a furnace with excellent, programmable control over both the heating and cooling rates to manage shrinkage uniformly.

Mastering temperature control is what elevates zirconia fabrication from a variable process to a predictable science, ensuring consistent and reliable outcomes for every case.

Summary Table:

| Temperature Control Aspect | Impact on Zirconia Sintering |

|---|---|

| Heating Ramp | Prevents thermal shock and micro-cracks |

| Soaking Phase (1450-1600°C) | Ensures uniform densification for strength and translucency |

| Controlled Cooling | Reduces internal stress to avoid brittleness and warping |

| Accuracy (±1°C) | Prevents under-sintering (weakness) and over-sintering (brittleness) |

Struggling with inconsistent zirconia sintering results? At KINTEK, we specialize in advanced high-temperature furnace solutions tailored for dental labs and clinics. Leveraging exceptional R&D and in-house manufacturing, our Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems offer precise temperature control within ±1°C, ensuring your zirconia restorations achieve optimal strength, perfect fit, and superior aesthetics. Our deep customization capabilities allow us to meet your unique experimental needs, reducing remakes and enhancing efficiency. Contact us today to discuss how our furnaces can transform your sintering process and deliver reliable outcomes for every case!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- Why is calibration important for dental sintering furnaces? Ensure Perfect Restorations and Avoid Costly Failures

- What factors should be considered when choosing a dental sintering furnace? Ensure Quality and Efficiency for Your Lab

- What factors determine the quality of sintered zirconia restorations? Master Material, Equipment, and Technique

- How has the sintering process innovated dental zirconia applications? Boost Strength, Precision, and Efficiency

- What are some common mistakes when operating dental sintering furnaces? Avoid Costly Errors for Perfect Zirconia Restorations