At their core, support rollers in a rotary cement kiln serve two critical functions. They bear the immense weight of the entire rotating structure and provide precise horizontal forces to keep the kiln stable and properly aligned during operation.

A rotary kiln is a massive, heavy, rotating piece of industrial machinery. The support rollers are the fundamental mechanical solution that allows this giant to turn smoothly while safely managing the enormous vertical and horizontal forces involved.

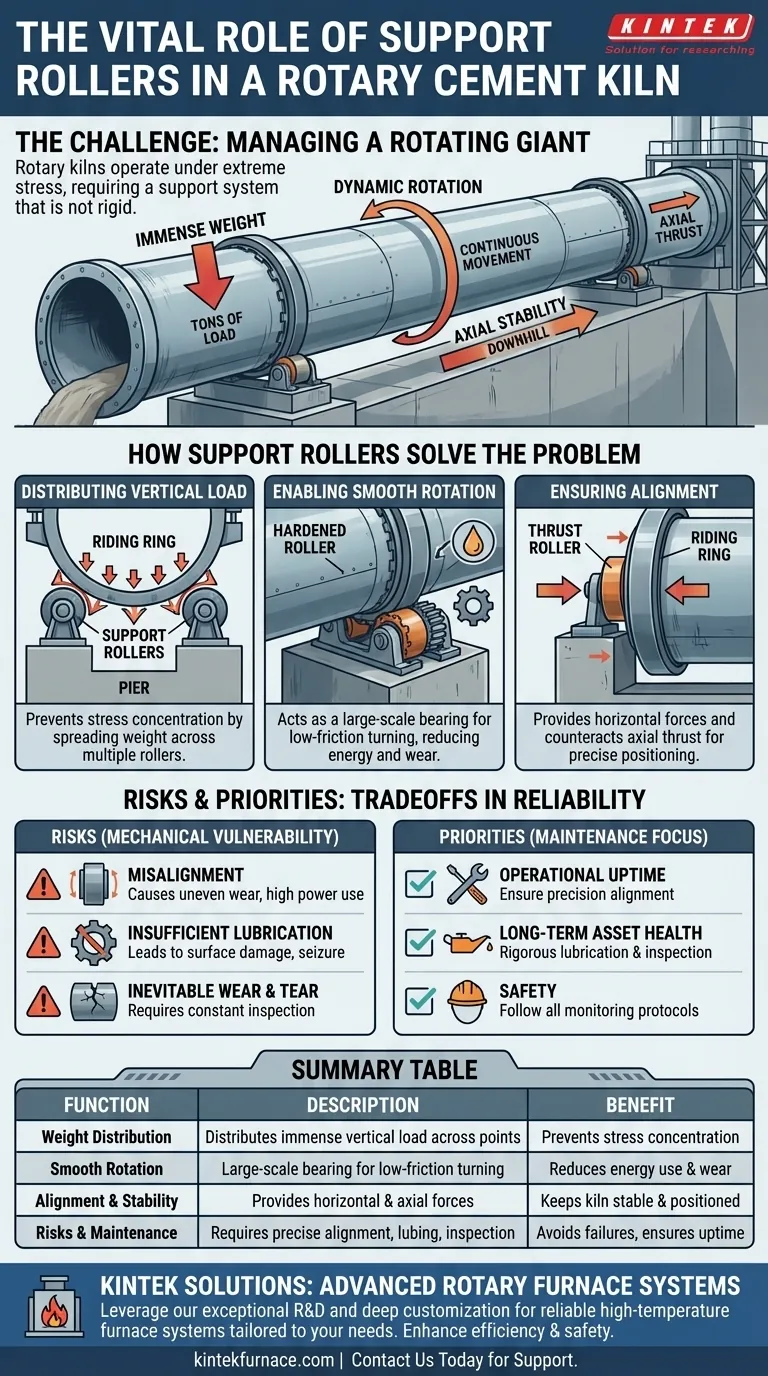

The Challenge: Managing a Rotating Giant

To understand the role of support rollers, you must first appreciate the extreme mechanical demands of a rotary kiln. It is not simply a static furnace; it is a dynamic system operating under immense stress.

The Kiln's Immense Weight

The body of a rotary kiln is a huge steel cylinder. It is lined with heavy refractory bricks to withstand internal temperatures and is constantly filled with tons of raw material being processed. This creates a massive vertical load due to gravity.

The Dynamics of Rotation

The kiln must rotate continuously to tumble and convey the material through the heating process. This means its support system cannot be rigid; it must facilitate smooth, low-friction movement for a structure weighing hundreds or even thousands of tons.

The Need for Axial Stability

Most kilns are installed at a slight angle to help material flow. This inclination, combined with the rotation, creates a constant axial thrust—a tendency for the entire kiln to slide "downhill." The support system must counteract this force to keep the kiln from moving off its foundation.

How Support Rollers Solve the Problem

Support rollers are the engineered answer to these challenges. They are not just simple wheels; they are a precision system designed for high-load, continuous-duty applications.

Distributing the Vertical Load

The kiln is supported by several sets of rollers, known as piers or stations, spaced along its length. Each set consists of two or more rollers that cradle a massive steel "riding ring" or "tire" attached to the kiln shell. This design distributes the total weight, preventing stress from concentrating on any single point.

Enabling Smooth Rotation

The hardened, polished surfaces of the rollers and riding rings act as a large-scale bearing. This allows the immense mass of the kiln to turn with minimal friction, which is critical for reducing energy consumption and mechanical wear on the drive system.

Ensuring Horizontal and Axial Alignment

The rollers provide the inward horizontal forces that keep the cylindrical kiln perfectly cradled. Furthermore, specialized thrust rollers are often used. These rollers push against the side of the riding rings to counteract the axial drift, ensuring the kiln remains in its precise longitudinal position.

Understanding the Trade-offs and Risks

While robust, the support roller system is a point of mechanical vulnerability. Failure to manage it properly leads to significant operational problems and safety hazards.

The Criticality of Alignment

Even minor misalignment of the support rollers can cause immense problems. It leads to uneven wear on the rollers and riding rings, increases the power required to turn the kiln, and can induce dangerous stresses in the kiln shell itself.

The Danger of Insufficient Lubrication

The contact points between the rollers and the riding rings are under extreme pressure. Proper lubrication is essential to manage friction and heat. Inadequate lubrication can lead to surface damage, high energy costs, and eventual seizure.

Inevitable Wear and Tear

Despite being made of hardened steel, support rollers are subject to constant wear. Regular inspection for surface pitting, spalling, or cracking is a non-negotiable part of any preventative maintenance program. Ignoring wear can lead to catastrophic roller failure.

Key Priorities for Kiln Reliability

Because the rotary kiln is the "heart of the cement factory," the reliability of its support system is paramount. Your maintenance and operational focus should reflect this reality.

- If your primary focus is operational uptime: Your most critical task is ensuring the precision alignment of all support rollers to prevent unplanned shutdowns.

- If your primary focus is long-term asset health: Implement a rigorous lubrication and surface inspection program for both the rollers and the kiln's riding rings.

- If your primary focus is safety: Recognize that a roller failure is a catastrophic mechanical event and ensure all monitoring and inspection protocols are followed without exception.

Ultimately, mastering the mechanics of the support roller system is fundamental to ensuring the safe, efficient, and continuous operation of the entire cement plant.

Summary Table:

| Function | Description |

|---|---|

| Weight Distribution | Distributes kiln's immense vertical load across multiple points to prevent stress concentration. |

| Smooth Rotation | Acts as a large-scale bearing for low-friction turning, reducing energy use and wear. |

| Alignment and Stability | Provides horizontal forces and counteracts axial thrust to keep the kiln stable and properly positioned. |

| Risks and Maintenance | Requires precise alignment, lubrication, and regular inspection to avoid failures and ensure uptime. |

Ensure your rotary kiln operates at peak performance with KINTEK's advanced solutions. Leveraging exceptional R&D and in-house manufacturing, we provide diverse industries with reliable high-temperature furnace systems, including Rotary Furnaces, tailored to your specific needs. Our strong deep customization capability ensures precise alignment with your operational requirements, enhancing efficiency and safety. Contact us today to discuss how we can support your kiln's reliability and longevity!

Visual Guide

Related Products

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- How is bed depth controlled in a rotary kiln and why is it important? Optimize Heat Transfer and Efficiency

- What advantages do electrically heated rotary kilns offer in temperature control? Achieve Precision and Uniformity for Superior Results

- How does the raw meal move inside the rotary kiln? Master Controlled Flow for Efficient Processing

- What are the main components in the construction of a rotary kiln? A Guide to the Core Systems

- Why is a Rotary Kiln specifically suitable for treating high-carbon FMDS? Turn Waste Carbon into a Resource