At its core, an induction furnace operates on the principle of electromagnetic induction and Joule heating. An alternating electrical current flows through a copper coil, generating a rapidly reversing magnetic field. When a conductive material like metal is placed within this field, the field induces circular electrical currents, known as "eddy currents," directly inside the metal. These currents, flowing against the material's own electrical resistance, generate intense, localized heat, causing the material to melt from the inside out.

Unlike traditional furnaces that heat a material externally, an induction furnace uses a magnetic field to make the material its own heat source. This fundamental difference is the key to its speed, efficiency, and precision.

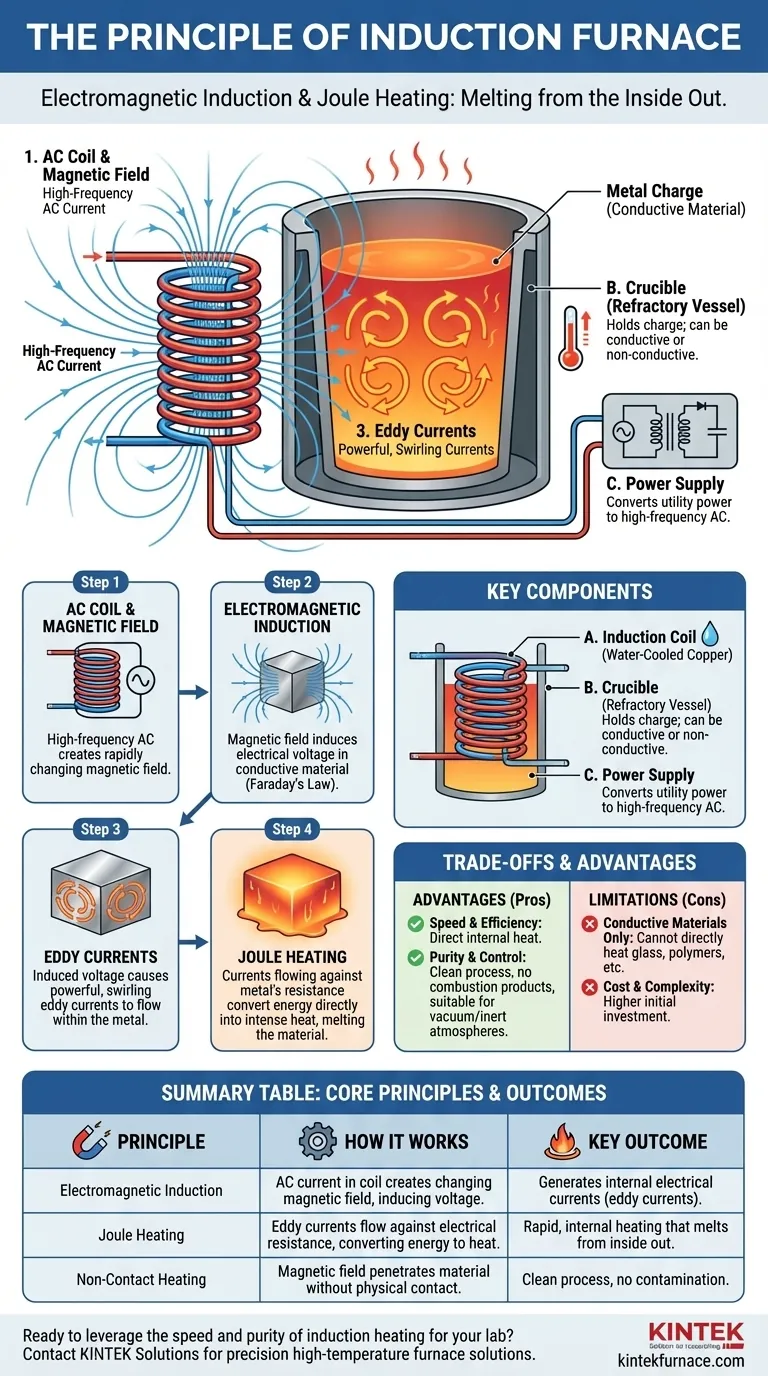

How Induction Heating Works: A Step-by-Step Breakdown

To truly grasp the principle, it's helpful to break it down into the sequence of physical events that occur. Each step directly enables the next, culminating in the melting of the metal.

The AC Coil and the Magnetic Field

An induction furnace begins with a powerful coil, typically made of copper tubing. A high-frequency alternating current (AC) is passed through this coil.

This AC current creates a dynamic and rapidly changing magnetic field in the space within and around the coil. The frequency of the current determines the characteristics of this field and the heating effect.

Electromagnetic Induction

This is the central scientific principle at play, described by Faraday's Law of Induction. When a conductive material (the "charge") is placed inside the coil, the fluctuating magnetic field induces an electrical voltage within the material.

Crucially, the magnetic field does not need to physically touch the material; it penetrates it directly.

The Role of Eddy Currents

The induced voltage causes powerful, swirling electrical currents to flow within the metal charge. These are known as eddy currents.

Think of them as small, circular whirlpools of electricity spinning inside the material, energized by the external magnetic field.

Joule Heating: From Current to Heat

All materials have some electrical resistance. As the eddy currents flow through the metal, they encounter this resistance.

The energy expended to overcome this resistance is converted directly into heat. This phenomenon is known as Joule heating. This internal heat generation is what rapidly raises the material's temperature to its melting point.

The Key Components of an Induction Furnace

The working principle is brought to life through several critical components working in concert.

The Induction Coil

This is the heart of the furnace. It is almost always made of hollow copper tubing so that cooling water can be passed through it. The immense electrical currents involved would otherwise cause the coil itself to overheat and melt.

The Crucible

This is the refractory vessel or container that holds the metal charge. Its material is critical.

- Non-conductive crucibles (e.g., ceramic) are used when you want to heat only the metal charge. The magnetic field passes through the crucible and induces current solely in the metal.

- Conductive crucibles (e.g., graphite) are heated by the magnetic field alongside the charge. This is useful for melting non-conductive materials via heat transfer from the crucible.

The Power Supply

The furnace requires a specialized power supply to convert standard utility power (e.g., 50/60 Hz) into the high-frequency AC needed for the coil. This unit consists of transformers, a high-frequency inverter, and capacitor banks.

Understanding the Trade-offs and Advantages

No technology is perfect for every application. The principle of induction heating creates a distinct set of pros and cons.

Advantage: Speed and Efficiency

Because heat is generated directly within the material, melting is extremely fast and energy-efficient. There is very little waste heat compared to a fuel-fired furnace, where heat must first saturate a chamber and then slowly penetrate the material from the outside.

Advantage: Purity and Control

Induction heating is a clean process. There are no products of combustion (like in a gas furnace) to contaminate the metal. This also allows for melting to occur under a vacuum or in an inert gas atmosphere, which is essential for producing high-purity alloys and handling reactive metals.

Limitation: Conductive Materials Only

The core principle relies entirely on inducing current in the workpiece. Therefore, standard induction furnaces cannot directly heat non-conductive materials like glass, polymers, or most ceramics.

Limitation: Cost and Complexity

The high-frequency power supplies and water-cooled copper coils make induction furnaces more complex and carry a higher initial investment cost compared to simpler resistance or fuel-fired furnaces.

Making the Right Choice for Your Goal

Your application's primary objective will determine if an induction furnace is the correct tool.

- If your primary focus is material purity and precision: Induction is the superior choice due to its clean, non-contact heating and its compatibility with vacuum or inert atmospheres.

- If your primary focus is speed and energy efficiency: The direct, internal heating of an induction furnace offers significant throughput and operational cost advantages for melting metals.

- If your primary focus is low initial cost or heating non-conductors: A different technology, like a conventional resistance or gas-fired box furnace, is likely a more suitable choice.

By understanding that induction heating effectively turns the material into its own heat source, you can leverage its unique advantages for the most demanding metallurgical applications.

Summary Table:

| Key Principle | How It Works | Key Outcome |

|---|---|---|

| Electromagnetic Induction | AC current in a coil creates a changing magnetic field, inducing voltage in conductive metal. | Generates internal electrical currents (eddy currents) within the metal. |

| Joule Heating | Eddy currents flow against the metal's electrical resistance, converting energy directly into heat. | Rapid, internal heating that melts the metal from the inside out. |

| Non-Contact Heating | The magnetic field penetrates the material and crucible without physical contact. | Clean process with no contamination from combustion gases. |

Ready to leverage the speed and purity of induction heating for your lab? At KINTEK, we combine exceptional R&D with in-house manufacturing to deliver advanced high-temperature furnace solutions. Whether you need a standard induction furnace or a deeply customized system for unique experimental requirements, our product line—including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—is designed for precision and performance. Contact our experts today to discuss how we can tailor a solution to meet your specific metal melting goals.

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What are the main applications of vacuum induction melting (VIM) furnaces? Achieve Unmatched Metal Purity for Critical Industries

- How does vacuum induction melting work? Achieve Ultra-Pure, High-Performance Alloys

- How is operator safety ensured during the vacuum induction melting process? Discover Multi-Layered Protection for Your Lab

- What components make up a Vacuum Induction Melting Furnace? Discover the Key Systems for Pure Metal Melting

- What are the key benefits of using vacuum melting furnaces? Achieve Superior Purity and Control for High-Performance Alloys