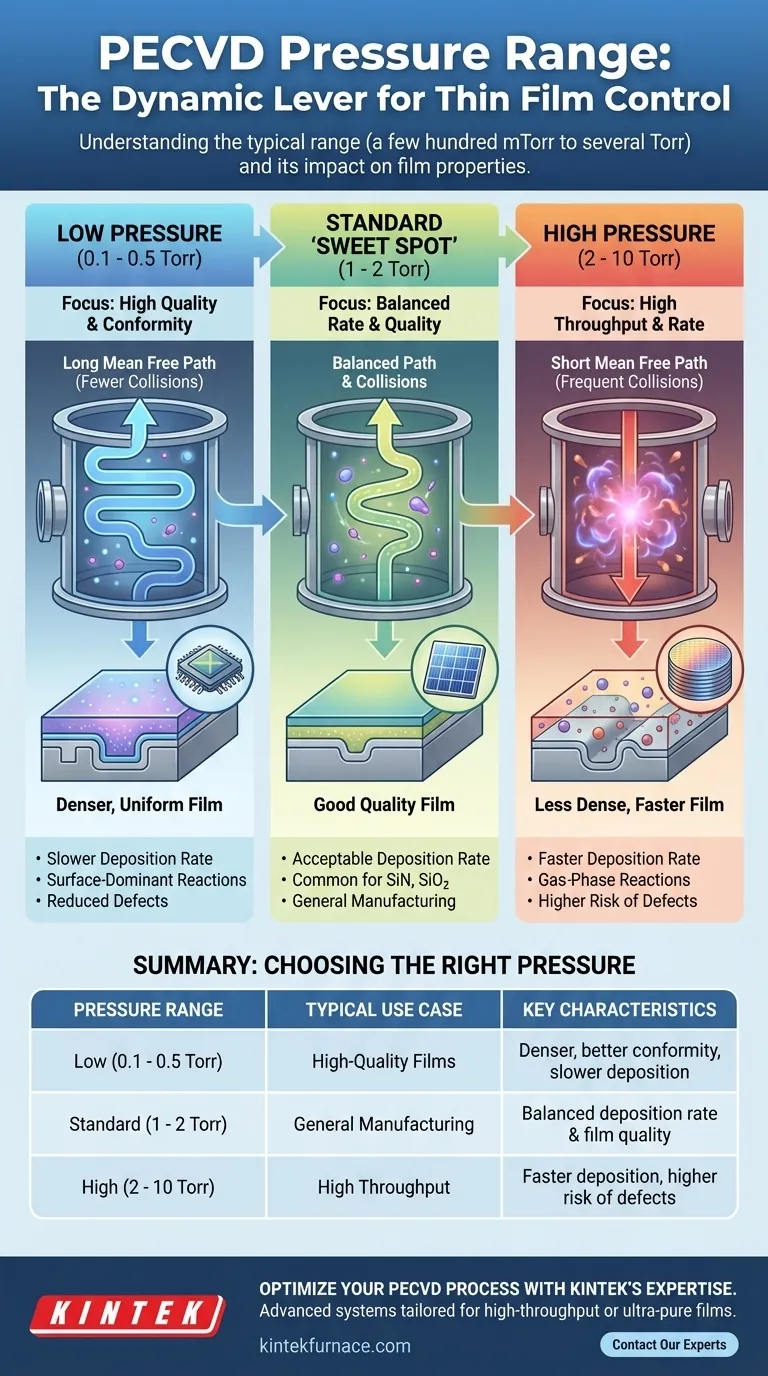

In a typical process, Plasma-Enhanced Chemical Vapor Deposition (PECVD) operates within a low-vacuum pressure range of a few hundred millitorr (mTorr) to several Torr. The most common operational window is between 1 and 2 Torr, but the exact pressure is highly dependent on the specific material being deposited and the desired film properties. This range is carefully selected to control the plasma characteristics and the chemical reactions that form the final film.

The core principle to understand is that pressure in PECVD is not a static setting, but a dynamic lever. It directly controls the frequency of molecular collisions, which in turn dictates the balance between deposition rate, film quality, and uniformity. Adjusting pressure allows you to fundamentally alter the nature of the deposition process.

The Role of Pressure in the PECVD Process

To understand why a specific pressure range is used, we must look at how it influences the physics of the plasma and the chemistry of the deposition. The goal is to generate reactive chemical species in the plasma that then land on a substrate to form a high-quality thin film.

Defining the Pressure Regimes

The references you'll find often cite slightly different numbers because "PECVD" is a broad term covering many applications. The values typically fall into two main categories after converting units (1 Torr ≈ 133 Pascals):

- Low Pressure (0.1 - 0.5 Torr): This range, from tens to hundreds of mTorr, is used for processes demanding high film quality.

- Standard Pressure (1 - 10 Torr): This is the most common range, offering a balance of speed and quality for applications like microelectronics and solar cell manufacturing.

Impact on Mean Free Path

Pressure's most direct physical consequence is on the mean free path—the average distance a gas molecule travels before colliding with another.

- At higher pressures, the mean free path is very short. Molecules collide frequently, leading to more chemical reactions occurring in the gas phase before the reactants reach the substrate.

- At lower pressures, the mean free path is long. Molecules are more likely to travel directly from the plasma source to the substrate, meaning most reactions happen on the surface of the film itself.

Influence on Plasma and Film Growth

This difference in mean free path directly influences the plasma and the resulting film.

At higher pressures, frequent collisions lead to a higher-density but lower-energy plasma. This often increases the deposition rate but can also lead to gas-phase nucleation, where particles form in the plasma and fall onto the film as defects.

At lower pressures, fewer collisions result in a lower-density but higher-energy plasma. This environment favors surface-dominant reactions, which typically produces a denser, more uniform, and higher-quality film, albeit at a slower deposition rate.

Understanding the Trade-offs

Choosing a pressure is a critical optimization step that involves balancing competing priorities. There is no single "best" pressure; there is only the best pressure for a specific goal.

High-Pressure Deposition (>1 Torr)

- Benefit: Primarily used to achieve a high deposition rate, which is crucial for manufacturing thick films or for increasing wafer throughput.

- Drawback: Can result in films with lower density, higher hydrogen content (for silane-based processes), and poorer conformity over complex surface topography. The risk of particle contamination from gas-phase reactions is also higher.

Low-Pressure Deposition (<500 mTorr)

- Benefit: Ideal for creating high-quality, dense, and stoichiometric films with excellent step coverage (conformity). This is essential for advanced microelectronic devices where film integrity is paramount.

- Drawback: The primary trade-off is a significantly slower deposition rate, which can impact manufacturing cost and throughput.

The Common "Sweet Spot"

The reason many standard PECVD processes for materials like silicon nitride (SiN) or silicon dioxide (SiO₂) operate in the 1 to 2 Torr range is that it provides a workable compromise. It delivers an acceptable deposition rate for manufacturing efficiency while maintaining film quality that is sufficient for passivation and dielectric layers.

Selecting the Right Pressure for Your Process

Your choice of pressure should be dictated entirely by the end goal for your thin film.

- If your primary focus is maximum throughput and deposition rate: Lean toward the higher end of the pressure range (e.g., 2-5 Torr), but monitor for particle defects.

- If your primary focus is ultimate film quality, density, and conformity: Use a lower pressure (e.g., 100-500 mTorr) and accept the slower deposition time.

- If you are developing a standard passivation or dielectric layer: Begin your process development in the common 1-2 Torr range and optimize from there based on your specific film requirements.

Ultimately, pressure is one of the most powerful parameters you can adjust to steer your PECVD process toward the desired outcome.

Summary Table:

| Pressure Range | Typical Use Case | Key Characteristics |

|---|---|---|

| Low (0.1 - 0.5 Torr) | High-Quality Films | Denser films, better conformity, slower deposition |

| Standard (1 - 2 Torr) | General Manufacturing (SiN, SiO₂) | Balanced deposition rate and film quality |

| High (2 - 10 Torr) | High Throughput | Faster deposition, higher risk of defects |

Optimize Your PECVD Process with KINTEK's Expertise

Mastering pressure control is just one part of achieving perfect thin films. At KINTEK, we leverage our exceptional R&D and in-house manufacturing to provide advanced PECVD systems tailored to your unique requirements. Whether you need high-throughput production or ultra-pure, high-conformity films, our deep customization capabilities ensure your furnace solution is precisely engineered for success.

Ready to enhance your deposition process? Contact our experts today to discuss how our PECVD systems can drive your research and production forward.

Visual Guide

Related Products

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

People Also Ask

- What are the classifications of CVD based on vapor characteristics? Optimize Your Thin Film Deposition Process

- What are the advantages of using CVD? Achieve High-Purity, Conformal Thin Films for Your Applications

- What parameters control the quality of PECVD-deposited films? Master Key Variables for Superior Film Properties

- How does PECVD contribute to semiconductor manufacturing? Enable Low-Temperature, High-Quality Film Deposition

- What are the drawbacks of CVD compared to PECVD? Key Limitations for Your Lab