At its core, a porcelain furnace is the critical laboratory instrument used to fire and sinter ceramic materials, transforming them into durable, natural-looking dental restorations. It is the essential tool that enables the fabrication of prosthetics like crowns, bridges, and veneers by applying precisely controlled heat in a specific atmosphere to bond material particles together.

The true role of a porcelain furnace extends beyond simple heating. It is a precision instrument that facilitates the molecular transformation of ceramic powders into a dense, strong, and aesthetically pleasing solid, a process fundamental to modern restorative dentistry.

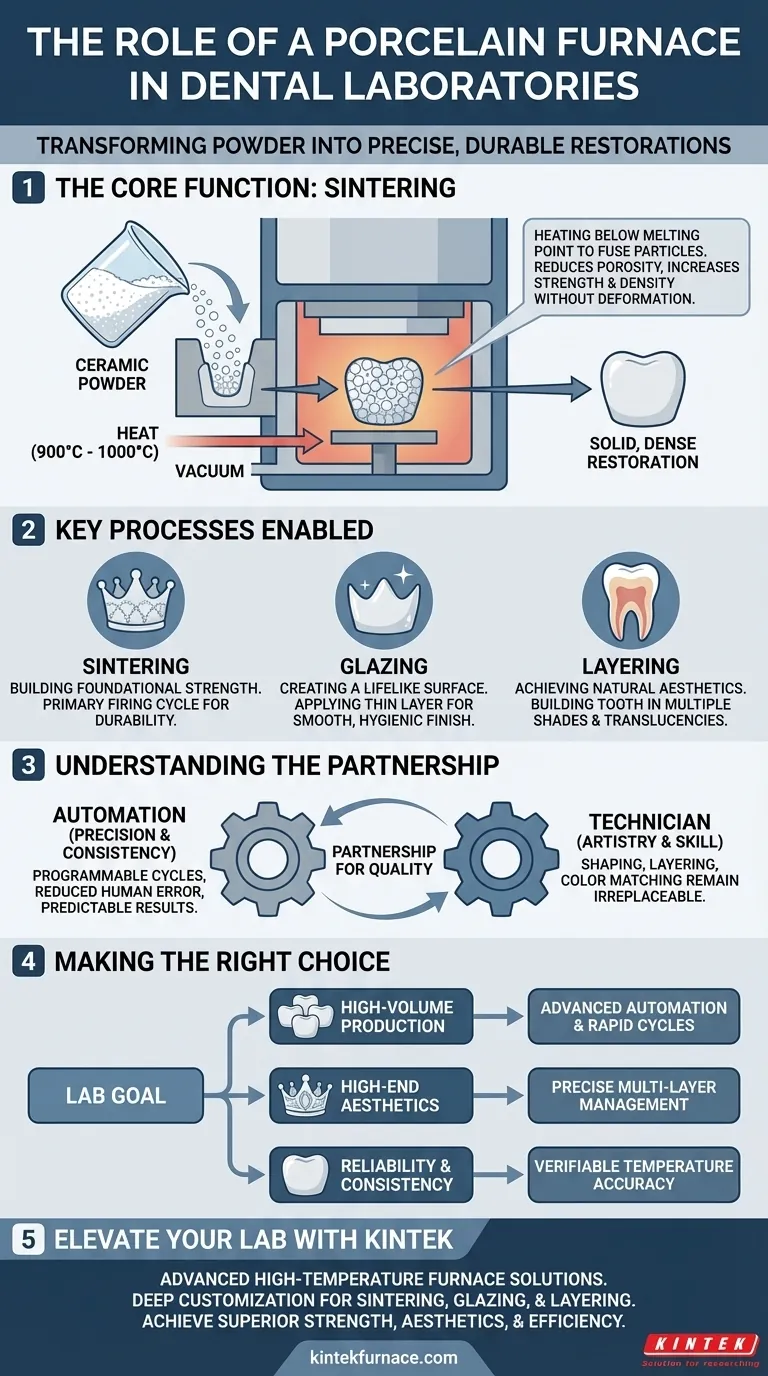

The Core Function: Transforming Powder into Prosthetics

A porcelain furnace's primary job is to execute a process called sintering. This single function is the foundation upon which all high-quality ceramic restorations are built.

What is Sintering?

Sintering is the process of heating a material, like porcelain powder, to a specific temperature just below its melting point.

At this temperature, the individual particles fuse together at their contact points. This reduces porosity and dramatically increases the material's overall strength and density without deforming its shape.

The Importance of Precise Heat Control

The furnace must maintain an exceptionally precise temperature, typically between 900°C and 1000°C.

If the temperature is too low, the particles won't bond sufficiently, resulting in a weak and brittle restoration. If it's too high, the material will melt, losing its carefully crafted shape and internal structure.

The Role of a Controlled Atmosphere

Modern furnaces also manage the atmosphere inside the firing chamber, often creating a vacuum. This removes impurities and ensures the chemical bonding process occurs correctly, resulting in a stronger, more predictable outcome.

Key Processes Enabled by a Porcelain Furnace

The furnace is not used for just one task but is central to a multi-stage workflow. Each stage leverages the furnace's capabilities to achieve a different clinical goal.

Sintering: Building Foundational Strength

This is the primary firing cycle that creates the core structure of the restoration. It turns the loosely packed ceramic material into a solid, durable prosthetic capable of withstanding the forces of chewing.

Glazing: Creating a Lifelike, Hygienic Surface

After the restoration is shaped and sintered, a final, thin layer of glaze is applied and fired at a specific temperature. This creates a smooth, non-porous surface that mimics the luster of natural tooth enamel.

A glazed surface is also more stain-resistant and hygienic, as it prevents plaque accumulation.

Layering: Achieving Natural Aesthetics

To create truly lifelike restorations, technicians build up the tooth in multiple, thin layers of different shades and translucencies of porcelain.

The furnace allows for each individual layer to be fired and fused separately. This meticulous process is what allows a skilled technician to replicate the complex visual properties of a natural tooth.

Understanding the Key Considerations

While modern furnaces are highly automated, their effectiveness still depends on understanding their function and limitations.

Automation Enhances Consistency

Modern furnaces feature programmable cycles, automatic temperature calibration, and precision motor drives. These advancements reduce the chance of human error and ensure that every restoration is fired under the exact same conditions, leading to highly consistent and predictable results.

The Furnace as a Tool, Not the Artist

Despite automation, the final quality of a restoration is a partnership between the machine and the technician. The furnace provides the controlled environment, but the technician's skill in shaping, layering, and color matching remains irreplaceable.

Precision Comes at a Cost

A high-quality dental furnace is a significant investment. The cost is justified by its ability to produce reliable, high-strength, and aesthetically superior restorations that minimize costly remakes and ensure patient satisfaction.

Making the Right Choice for Your Goal

The specific features you prioritize in a furnace should align directly with the primary goals of your dental laboratory.

- If your primary focus is high-volume production: Prioritize furnaces with advanced automation, multi-stage programming, and rapid firing cycles to maximize efficiency and throughput.

- If your primary focus is high-end aesthetic restorations: The furnace's ability to precisely manage complex, multi-layer firing programs is the most critical feature.

- If your primary focus is reliability and consistency: A robust furnace with verifiable temperature accuracy is the non-negotiable baseline, as this directly impacts the strength and fit of every restoration.

Ultimately, the porcelain furnace is the cornerstone technology that allows a dental lab to merge material science with artistry.

Summary Table:

| Key Aspect | Description |

|---|---|

| Primary Function | Sintering ceramic powders to create durable dental restorations like crowns, bridges, and veneers. |

| Temperature Range | Typically 900°C to 1000°C for precise heat control to ensure strength and avoid deformation. |

| Atmosphere Control | Often uses vacuum to remove impurities, enhancing bonding and outcome predictability. |

| Key Processes | Sintering (core strength), Glazing (surface finish), and Layering (aesthetics). |

| Automation Benefits | Programmable cycles and automatic features for consistency and reduced human error. |

Elevate your dental lab's capabilities with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we offer products like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all with strong deep customization to meet your unique needs for sintering, glazing, and layering processes. Achieve superior strength, aesthetics, and efficiency in your restorations—contact us today to discuss how we can support your goals!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What is sintering in dental? The Key to Durable, High-Strength Zirconia Restorations

- Why is accurate temperature control important in dental furnaces? Ensure Perfect Restorations Every Time

- What safety measures should be followed when using a sintering furnace in dental labs? Ensure Safe, High-Quality Dental Restorations

- What are the benefits of using dental sintering and porcelain furnaces? Enhance Strength, Aesthetics, and Efficiency

- What are some key features of dental sintering and porcelain furnaces? Optimize Your Dental Lab's Workflow