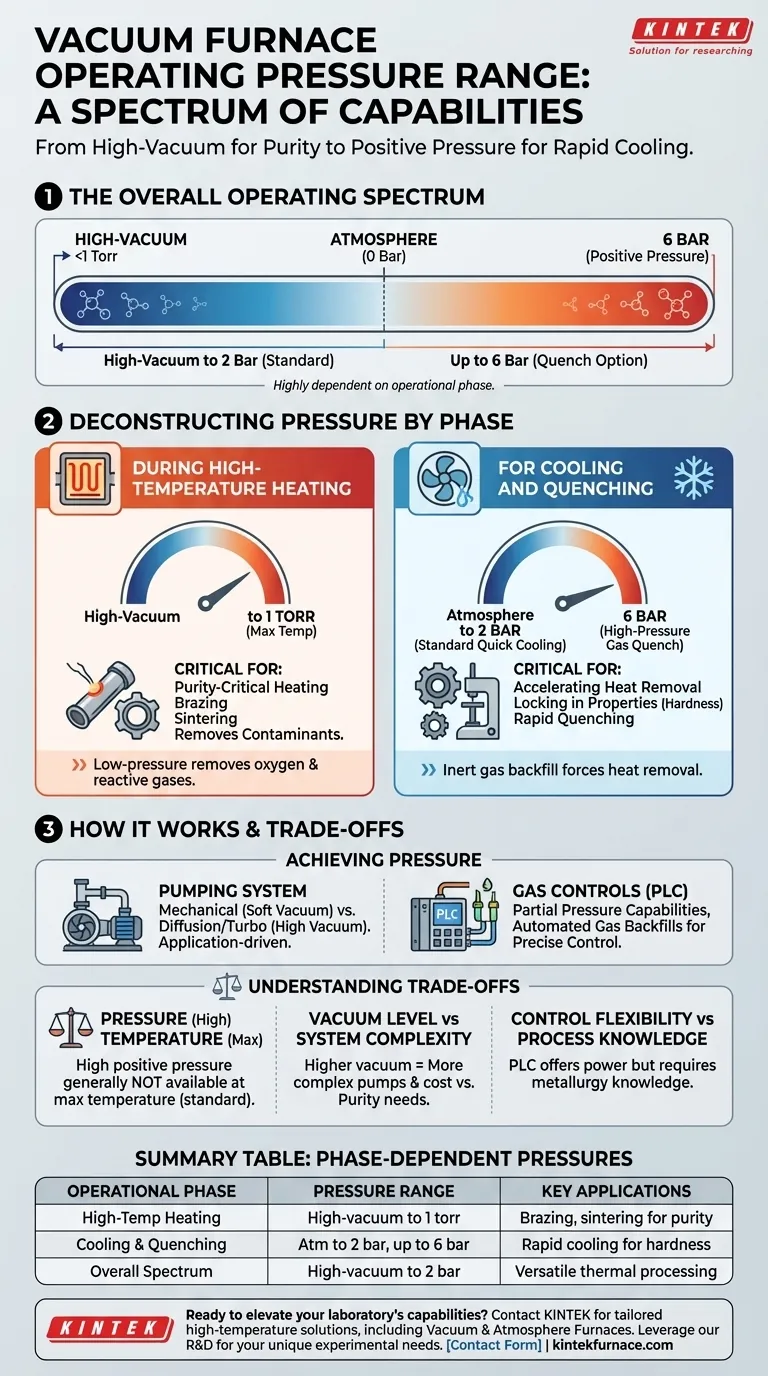

At its core, the vacuum furnace system operates across a remarkably wide pressure spectrum, from high-vacuum for purity-critical heating cycles to positive pressures up to 6 bar for rapid quenching operations. The specific pressure achievable is not a single value but is highly dependent on the operational phase—whether you are heating, holding at temperature, or cooling the workload.

A vacuum furnace's operating pressure is not one number, but a set of distinct capabilities tailored to different stages of a thermal process. Understanding the difference between its pressure range during heating versus cooling is critical to determining if it meets your technical requirements.

Deconstructing the Pressure Capabilities

To fully grasp the system's function, we must break down its pressure range by operational context. Each phase of a furnace cycle has different atmospheric requirements.

The Overall Operating Spectrum

The system's total pressure envelope spans from high-vacuum to 2 bar of positive pressure. This range allows it to handle processes that require an inert, contamination-free environment as well as processes that benefit from pressurized gas.

Pressure During High-Temperature Heating

During the most critical heating phases, the standard working pressure is limited. At maximum temperature, the furnace is designed to operate from high-vacuum up to 1 torr.

This low-pressure environment is essential for processes like brazing and sintering, as it removes oxygen and other reactive gases that could contaminate or oxidize the parts.

Pressure for Cooling and Quenching

In contrast, cooling cycles utilize positive pressure to accelerate heat removal. The system can use an inert gas backfill from atmosphere up to 2 bar for "quick cooling."

For applications requiring even faster cooling to lock in specific material properties (like hardness), a 6 bar high-pressure gas quench option is available. This forces gas through the hot zone at high velocity, providing maximum cooling rates.

How the System Achieves Different Pressures

The furnace's versatility comes from a combination of a sophisticated pumping system and precise gas controls, which work together to create the desired atmosphere at each stage.

The Role of the Pumping System

The ultimate vacuum level depends on the pumping configuration. The system can be equipped with a mechanical pump for achieving a "soft" vacuum or a more powerful diffusion or turbomolecular pump for reaching "high" vacuum levels.

This choice is application-driven. Basic degassing may only require a soft vacuum, while high-purity metal processing demands a high-vacuum environment.

Introducing Positive and Partial Pressures

The system is not limited to creating a vacuum. It features partial pressure capabilities using inert gases like argon or nitrogen.

A Programmable Logic Controller (PLC) automates gas backfills to maintain a specific low-pressure setpoint or to introduce positive pressure for cooling. This allows for precise atmospheric control throughout the entire thermal cycle.

Understanding the Trade-offs

While highly capable, the system's design involves inherent trade-offs between pressure, temperature, and equipment configuration that you must consider.

Pressure vs. Temperature

The most significant limitation is that high positive pressure is generally not available at maximum temperature in the standard configuration. The furnace is optimized for vacuum or low partial pressure during heating and uses high pressure primarily for cooling. Processes requiring high pressure during the high-temperature soak (like sinter-HIP) would necessitate a different furnace design.

Vacuum Level vs. System Complexity

Achieving a high vacuum requires a more complex and costly pumping system (diffusion or turbo pumps) compared to a standard mechanical pump. You must balance the need for atmospheric purity against budget and maintenance considerations. The choice should be dictated by your specific process requirements for cleanliness and outgassing.

Control Flexibility vs. Process Knowledge

The advanced PLC offers immense flexibility to program complex cycles involving ramps, soaks, vacuum levels, and gas backfills. However, leveraging this power requires a solid understanding of the process metallurgy to ensure the programmed cycle achieves the desired material outcome.

Matching the Furnace to Your Process

To make the right choice, evaluate the system's capabilities against the primary goal of your application.

- If your primary focus is high-purity processing or brazing: The furnace's ability to achieve high vacuum and maintain it up to 1 torr at temperature is the most critical feature for preventing oxidation.

- If your primary focus is controlling mechanical properties: The positive pressure cooling (2 bar) and high-pressure quench (6 bar) options are the key capabilities for manipulating material hardness and microstructure.

- If your primary focus is running complex, multi-stage cycles: The programmable controller with partial pressure and automatic gas backfill capabilities is essential for process automation and repeatability.

Understanding these distinct, phase-dependent pressure capabilities is the key to leveraging the furnace's full potential for your specific application.

Summary Table:

| Operational Phase | Pressure Range | Key Applications |

|---|---|---|

| High-Temperature Heating | High-vacuum to 1 torr | Brazing, sintering for purity |

| Cooling and Quenching | Atmosphere to 2 bar (standard), up to 6 bar (high-pressure quench) | Rapid cooling for hardness control |

| Overall Spectrum | High-vacuum to 2 bar positive pressure | Versatile thermal processing |

Ready to elevate your laboratory's capabilities with tailored high-temperature solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced furnace systems like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs, whether for high-purity processing, mechanical property control, or complex multi-stage cycles. Contact us today to discuss how our solutions can optimize your thermal processes and drive innovation!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- What are the proper procedures for handling the furnace door and samples in a vacuum furnace? Ensure Process Integrity & Safety

- What are the benefits of vacuum heat treatment? Achieve Superior Metallurgical Control

- What is the vacuum heat treatment process? Achieve Superior Surface Quality and Material Performance

- What are the functions of a high-vacuum furnace for CoReCr alloys? Achieve Microstructural Precision and Phase Stability

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today