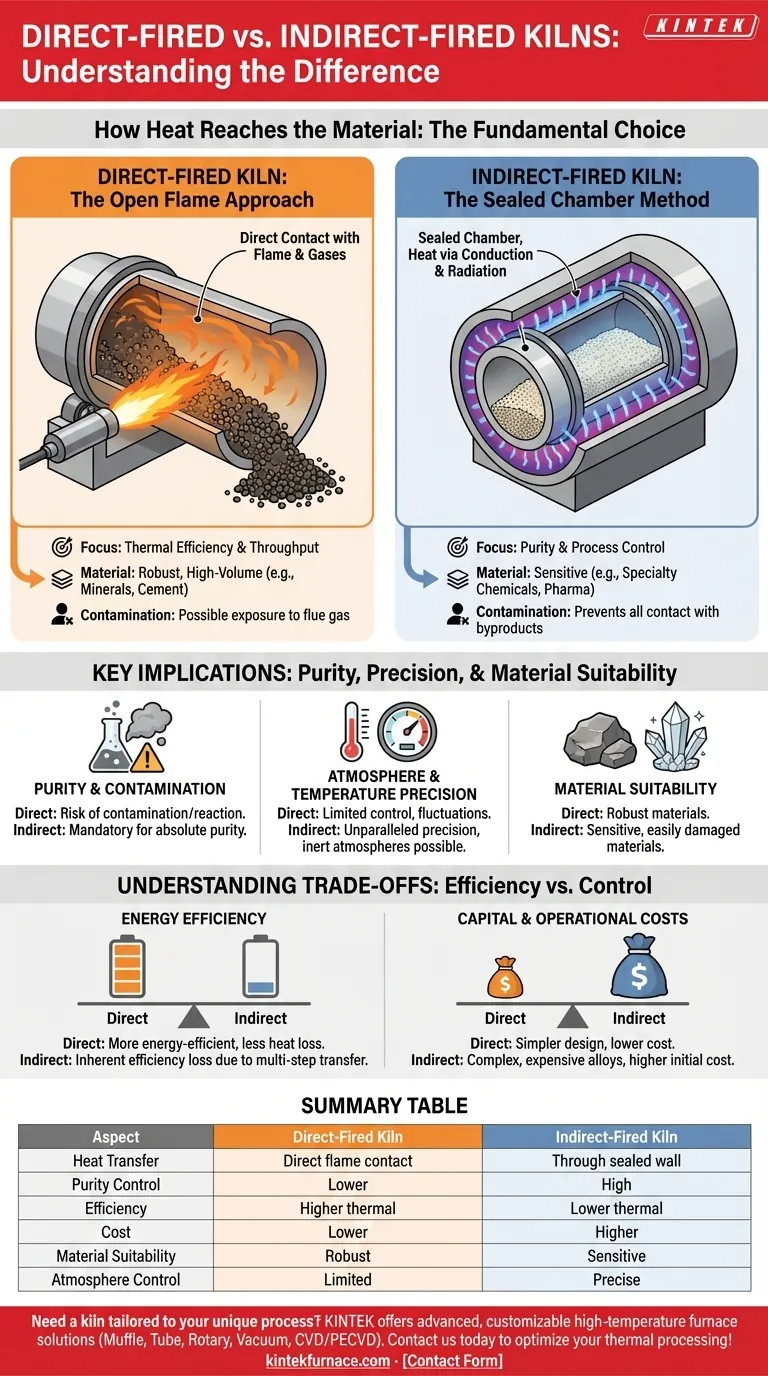

At its core, the difference between a direct-fired and an indirect-fired kiln lies entirely in how heat reaches the material being processed. In a direct-fired kiln, the material is in direct contact with the flame and its combustion gases. In contrast, an indirect-fired kiln heats the material inside a sealed chamber from the outside, preventing any contact with combustion byproducts.

The choice is not about which kiln is "better," but which is correct for the specific task. Direct-fired kilns prioritize thermal efficiency and throughput for robust materials, while indirect-fired kilns are engineered for purity and process control with sensitive materials.

How Heat is Transferred: The Fundamental Difference

Understanding the mechanism of heat transfer is the key to selecting the right technology. The two designs serve fundamentally different purposes based on this single principle.

Direct-Fired Kilns: The Open Flame Approach

In a direct-fired system, a burner injects a flame and hot combustion gases directly into the rotating kiln drum. These gases flow through the drum, tumbling with and heating the material through direct contact.

This method is highly efficient as the heat is applied straight to the source. It is ideal for processing materials that are not chemically altered or contaminated by exposure to combustion gases.

Indirect-Fired Kilns: The Sealed Chamber Method

An indirect-fired kiln isolates the material within a sealed rotating drum. This entire drum is then enclosed within a larger furnace or an external heating shroud.

Fuel is burned outside the processing drum, heating its shell. The heat then transfers through the drum wall to the material inside via conduction and radiation. This design completely prevents contamination.

Key Implications for Your Process

The method of heating creates a cascade of consequences that directly impact the final product, process control, and material suitability.

Purity and Contamination Control

This is the most critical deciding factor. Because direct firing exposes the material to flue gas, it can introduce contaminants and cause unwanted chemical reactions.

For applications in specialty chemicals, food processing, or pharmaceuticals where product purity is non-negotiable, an indirect-fired kiln is the only viable option.

Atmosphere and Temperature Precision

Indirect kilns provide unparalleled control over the processing environment. Since the drum is sealed, a specific atmosphere—such as an inert gas like nitrogen—can be introduced to prevent oxidation or facilitate a specific reaction.

This sealed design also allows for more uniform and precise temperature management, as there are no fluctuations from the direct flow of combustion gases.

Material Suitability

The choice is dictated by the material's tolerance.

Direct-fired kilns are the workhorses for robust, high-volume materials like minerals, cement, and certain ores where direct contact with flue gas has no negative effect on the end product.

Indirect-fired kilns are essential for sensitive materials that could be damaged, altered, or contaminated. This includes fine chemicals, carbon-based products, and any material requiring processing in an inert environment.

Understanding the Trade-offs: Efficiency vs. Control

Selecting a kiln requires balancing process requirements with operational realities like cost and energy consumption.

Energy Efficiency

Direct-fired kilns are generally more energy-efficient. By applying heat directly to the material, less energy is lost to the surrounding environment.

Indirect-fired kilns have an inherent efficiency loss. Heat must first transfer to the external furnace, then through the thick kiln shell, and finally to the material. This multi-step process results in lower overall thermal efficiency.

Capital and Operational Costs

Direct-fired systems are typically simpler in design and less expensive to manufacture and install. Their straightforward construction leads to lower capital investment.

Indirect-fired kilns are more complex. They require a secondary enclosure (the furnace) and often use expensive, high-temperature metal alloys for the sealed drum to ensure durability and effective heat transfer, leading to higher initial costs.

Making the Right Choice for Your Goal

Your decision depends entirely on the non-negotiable requirements of your material and process.

- If your primary focus is high throughput and cost-efficiency: A direct-fired kiln is the superior choice, provided your material is not sensitive to combustion gases.

- If your primary focus is absolute product purity and avoiding contamination: An indirect-fired kiln is mandatory to isolate your material from combustion byproducts.

- If your primary focus is precise atmosphere or temperature control: Select an indirect-fired kiln for its ability to manage the internal processing environment with exacting precision.

By understanding this fundamental distinction, you can select the precise thermal processing tool that aligns with both your technical requirements and financial objectives.

Summary Table:

| Aspect | Direct-Fired Kiln | Indirect-Fired Kiln |

|---|---|---|

| Heat Transfer | Direct contact with flame and gases | Heat through sealed chamber wall |

| Purity Control | Lower; exposure to combustion gases | High; no contamination from gases |

| Efficiency | Higher thermal efficiency | Lower thermal efficiency |

| Cost | Lower capital and operational costs | Higher capital and operational costs |

| Material Suitability | Robust materials (e.g., minerals, cement) | Sensitive materials (e.g., chemicals, pharmaceuticals) |

| Atmosphere Control | Limited control | Precise control with inert gases |

Need a kiln tailored to your unique process? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to precisely meet your experimental requirements. Whether you prioritize purity, efficiency, or specific material handling, our experts are ready to help. Contact us today to discuss how we can optimize your thermal processing!

Visual Guide

Related Products

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What is an electric heating rotary kiln and what industries use it? Discover Precision Heating for High-Purity Materials

- How does the raw meal move inside the rotary kiln? Master Controlled Flow for Efficient Processing

- What are the main components in the construction of a rotary kiln? A Guide to the Core Systems

- How is bed depth controlled in a rotary kiln and why is it important? Optimize Heat Transfer and Efficiency

- What are the uses of rotary kilns in the building materials industry besides cement clinker? Key Applications Explained