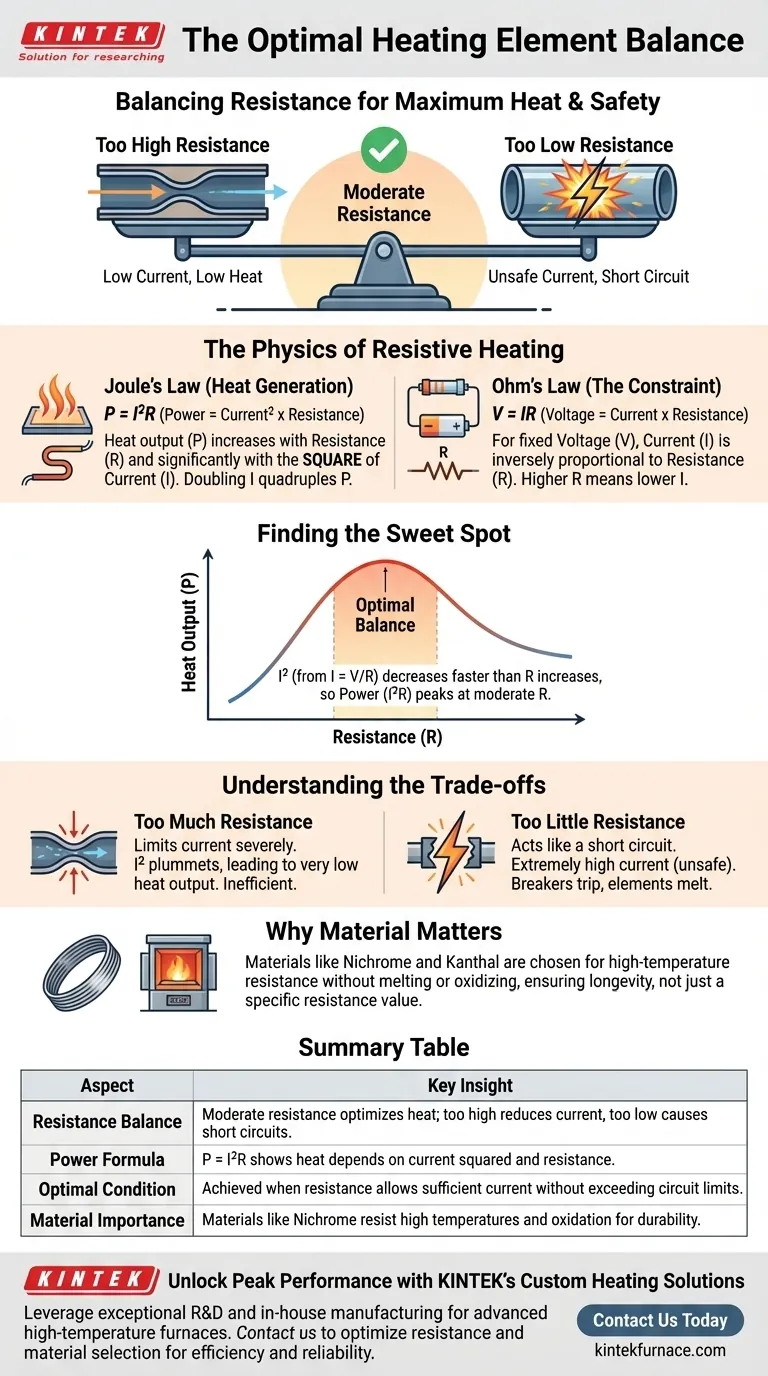

In short, the desired balance in a heating element is a moderate resistance. This resistance must be high enough to generate significant heat through opposition to electron flow, but low enough to permit a substantial electric current to pass through it from the power source.

The core principle is that maximum heat is not a product of maximum resistance. Instead, it is the result of optimizing the relationship between resistance and current. Pushing resistance too high chokes off the current, diminishing heat output, while too little resistance creates a near-short circuit that is inefficient and unsafe.

The Physics of Resistive Heating

To understand the need for this balance, we must look at the two fundamental laws governing the circuit: Joule's Law of heating and Ohm's Law. These two principles work in opposition, creating a "sweet spot" for heat generation.

Power, Current, and Resistance (P = I²R)

The amount of heat a resistive element generates is defined by its power output. This is calculated with the formula P = I²R, where P is power (heat), I is current, and R is resistance.

This formula shows that power increases with both resistance and the square of the current. This highlights the critical importance of current; doubling the current quadruples the heat output.

The Role of Voltage and Current (V = IR)

Ohm's Law, V = IR, introduces the balancing factor. It states that for a fixed voltage (V)—like that from a standard wall outlet—current (I) is inversely proportional to resistance (R).

In other words, if you increase the resistance of the element, you will decrease the current that can flow through it.

Finding the Optimal Balance

When we combine these two laws, the trade-off becomes clear. As you increase a heating element's resistance:

- The R term in the power formula (P = I²R) goes up, which works to increase heat.

- The I term in the power formula goes down (since I = V/R), which works to decrease heat.

Because the current term is squared (I²), its decrease has a much more dramatic impact than the linear increase in resistance. The greatest heat output is therefore achieved at a moderate resistance level where the combination of R and I² is at its peak.

Understanding the Trade-offs

Designing a heating element is an exercise in avoiding two unproductive extremes. Moving too far in either direction results in poor performance.

The Problem with Too Much Resistance

It's a common misconception that more resistance always equals more heat. If the resistance is excessively high, it will severely limit the current flowing through the circuit.

The resulting drop in current is so significant that the I² term in the power formula plummets, leading to very low overall power output. The element may get slightly warm, but it will not produce the intense heat required for its application.

The Problem with Too Little Resistance

An element with nearly zero resistance acts like a simple wire, approaching a short circuit. According to Ohm's Law, this will allow an extremely high, unsafe level of current to flow.

While the power formula might suggest this would generate immense heat, the system fails. The circuit's breaker will trip, a fuse will blow, or the element itself may melt almost instantly. It cannot sustainably convert electrical energy into useful thermal energy.

Why Material Choice Matters

Beyond a specific resistance value, the material itself is critical. Materials like Nichrome or Kanthal are chosen not just for their resistivity but because they are designed to withstand very high temperatures without melting or oxidizing (rusting), ensuring a long and stable operational life.

Making the Right Choice for Your Goal

Selecting the right resistance is about matching the component to the electrical system and the desired outcome.

- If your primary focus is maximum heat output: You must choose a moderate resistance that optimizes the

P = I²Rformula for your specific source voltage, rather than simply using the highest resistance you can find. - If your primary focus is safety and longevity: You must select a resistance that keeps the current draw well within the safe limits of your circuit and use a material engineered to endure the resulting high temperatures.

Ultimately, designing an effective heating element is a precise engineering exercise in balancing electrical principles, not just maximizing a single variable.

Summary Table:

| Aspect | Key Insight |

|---|---|

| Resistance Balance | Moderate resistance optimizes heat; too high reduces current, too low causes short circuits. |

| Power Formula | P = I²R shows heat depends on current squared and resistance. |

| Optimal Condition | Achieved when resistance allows sufficient current without exceeding circuit limits. |

| Material Importance | Materials like Nichrome resist high temperatures and oxidation for durability. |

Unlock Peak Performance with KINTEK's Custom Heating Solutions

Struggling to find the right balance for your heating elements? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all designed with strong deep customization capabilities to precisely meet your unique experimental requirements.

Whether you're aiming for maximum heat output or prioritizing safety and longevity, our experts can help you optimize resistance and material selection. Don't let inefficient heating hold you back—contact us today to discuss how we can enhance your laboratory's efficiency and reliability!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis

- How do you prevent maintenance on a muffle furnace? Extend Lifespan with Proactive Care

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production