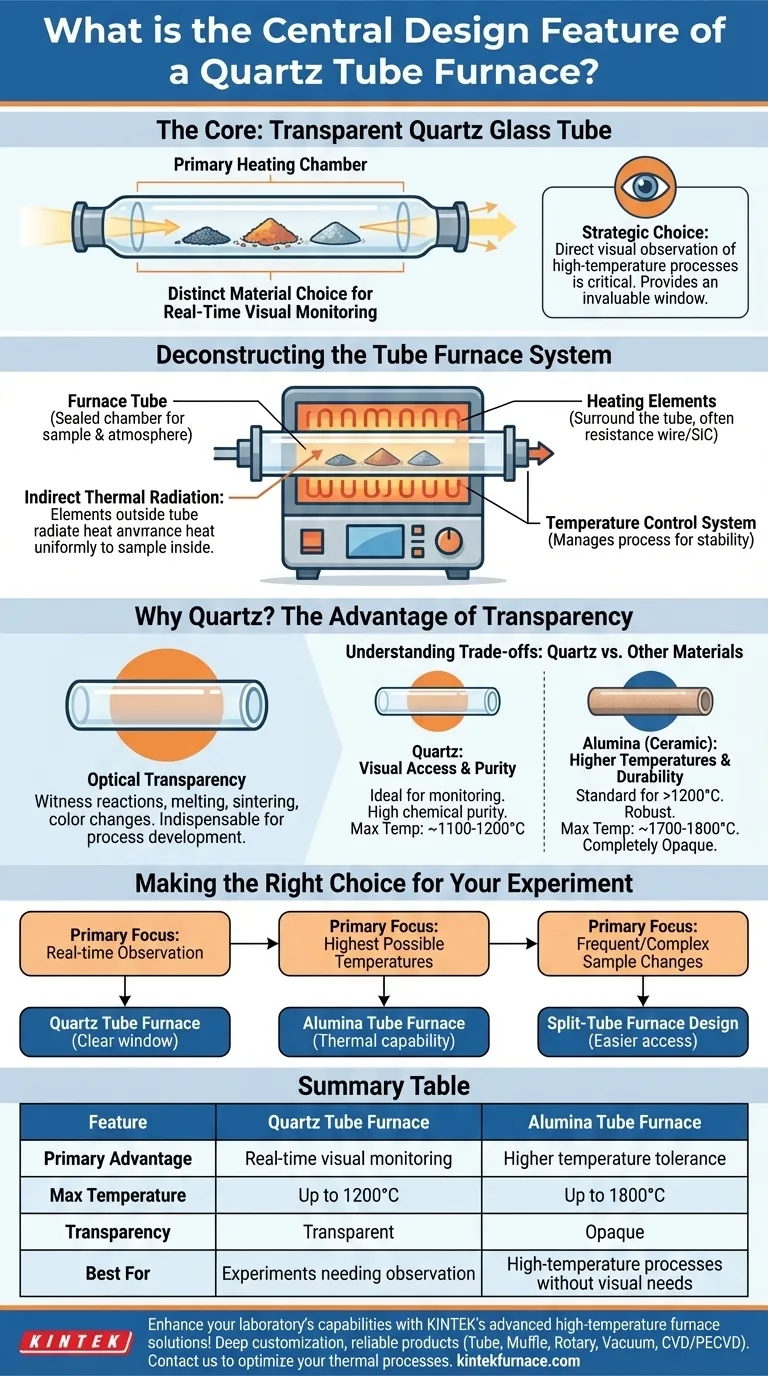

At its core, the central design feature of a quartz tube furnace is its transparent quartz glass tube, which functions as the primary heating chamber. This distinct material choice is what separates it from other furnace types, as it allows researchers to directly and visually monitor samples in real-time as they undergo thermal processing.

The decision to use a quartz tube is not merely for heat resistance; it is a strategic choice for experiments where direct visual observation is critical. The transparency of quartz provides an invaluable window into high-temperature processes that would otherwise be hidden.

Deconstructing the Tube Furnace System

A tube furnace is a high-temperature heating device used extensively in laboratory and industrial settings. While the tube itself is central, it operates as part of a larger, integrated system.

The Core Components

A typical tube furnace consists of three main parts: the furnace tube where the sample is placed, the heating elements that surround the tube, and the temperature control system that manages the process. These components work together to create a stable, controlled thermal environment.

The Furnace Tube: The Heart of the Operation

The furnace tube is the sealed chamber that contains the sample and a specific atmosphere (like vacuum, inert gas, or reactive gas). The material of this tube is the single most important factor defining the furnace's capabilities and applications.

Why Quartz? The Advantage of Transparency

The defining benefit of using quartz glass is its optical transparency. This allows you to witness reactions, melting, sintering, or color changes as they happen. For processes that are not fully understood, this visual feedback is indispensable for process development and scientific discovery.

How It Heats: Indirect Thermal Radiation

The heating elements, often made of resistance wire or silicon carbide, are positioned outside the quartz tube. They heat the tube's exterior, which in turn radiates heat uniformly to the sample inside. This indirect method protects the heating elements from any reactive gases or byproducts within the tube.

Understanding the Trade-offs: Quartz vs. Other Materials

Choosing a quartz tube furnace involves understanding its specific benefits and limitations compared to furnaces that use other materials, most commonly alumina ceramic.

Quartz: For Visual Access and Purity

Quartz is the ideal choice when visual monitoring is a priority. It also offers very high chemical purity, preventing contamination of sensitive samples. However, its primary limitation is temperature; most quartz tubes are rated for continuous use up to approximately 1100-1200°C.

Alumina (Ceramic): For Higher Temperatures and Durability

When experiments require temperatures exceeding 1200°C, alumina ceramic tubes are the standard. Alumina is more robust and can withstand much higher temperatures (often up to 1700-1800°C), but it is completely opaque. You sacrifice visual access for the ability to operate at extreme heat.

Design Variations: Split-Tube Furnaces

Separate from the tube material is the furnace body design. A split-tube furnace is hinged, allowing it to open lengthwise. This provides much easier access for loading complex sample holders or reactors, regardless of whether the internal tube is quartz or alumina.

Making the Right Choice for Your Experiment

The optimal furnace is the one that best matches your experimental goals. Consider the following to guide your decision.

- If your primary focus is real-time observation: A quartz tube furnace is the only choice that provides a clear window into your process.

- If your primary focus is reaching the highest possible temperatures: An alumina tube furnace will provide the necessary thermal capability, sacrificing visual access.

- If your primary focus is frequent or complex sample changes: A split-tube furnace design will significantly improve ease of use and reduce setup time.

Ultimately, understanding the role of the furnace tube empowers you to select the precise tool needed to answer your scientific question.

Summary Table:

| Feature | Quartz Tube Furnace | Alumina Tube Furnace |

|---|---|---|

| Primary Advantage | Real-time visual monitoring | Higher temperature tolerance |

| Max Temperature | Up to 1200°C | Up to 1800°C |

| Transparency | Transparent | Opaque |

| Best For | Experiments needing observation | High-temperature processes without visual needs |

Enhance your laboratory's capabilities with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with reliable products like Tube Furnaces, Muffle Furnaces, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental requirements, such as real-time monitoring with quartz tubes or high-temperature operations with alumina. Contact us today to discuss how we can optimize your thermal processes and drive your research forward!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents