In ceramics, reduction firing is a method that intentionally reduces the amount of oxygen inside a kiln during the firing process. This oxygen-starved atmosphere forces chemical changes that produce unique and often dramatic color effects in glazes and clay bodies. Because this technique relies on controlling combustion, it is performed in fuel-burning kilns, with gas kilns being the most common and effective type.

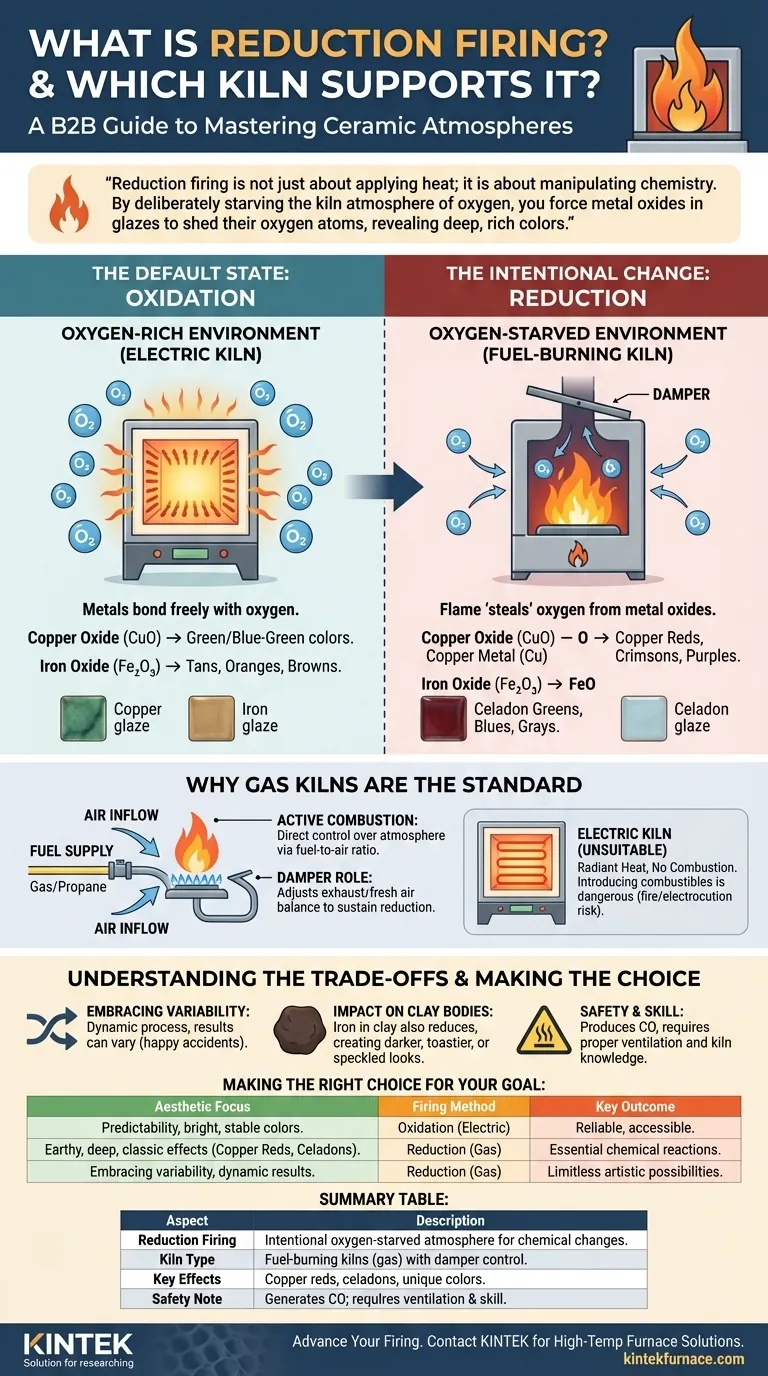

Reduction firing is not just about applying heat; it is about manipulating chemistry. By deliberately starving the kiln atmosphere of oxygen, you force metal oxides in glazes to shed their oxygen atoms, revealing deep, rich colors that are impossible to achieve in a standard, oxygen-rich firing.

The Chemistry of Kiln Atmospheres

To understand reduction, you must first understand its opposite: oxidation. Nearly every firing process falls into one of these two categories, and the choice fundamentally dictates the final appearance of your work.

The Default State: Oxidation

Oxidation is an oxygen-rich environment. This is the standard atmosphere in an electric kiln, where heating elements simply radiate heat without any flame.

In an oxidizing atmosphere, metals in the clay and glazes bond freely with oxygen. For example, copper oxide (CuO) remains oxidized and produces green or blue-green colors. Iron oxide produces predictable tans, oranges, and browns.

The Intentional Change: Reduction

Reduction is an oxygen-starved environment. This is achieved in a fuel-burning kiln by restricting airflow with a damper while increasing the fuel supply.

The flame, hungry for oxygen to continue burning, begins to pull it from other sources. It "steals" oxygen atoms directly from the metal oxides present in the glazes and the clay itself.

How Reduction Transforms Color

This chemical theft, or "reduction," is what creates the signature colors.

When copper oxide (CuO) is stripped of its oxygen, it reduces to pure, microscopic particles of copper metal (Cu). This elemental copper is what produces the famous and often elusive copper reds, crimsons, and purples.

Similarly, iron oxide (Fe₂O₃) reduces to a different state (FeO), creating the subtle and highly prized greens, blues, and grays of celadon glazes.

Why Gas Kilns Are the Standard

The ability to control the fuel-to-air ratio is the entire basis of reduction firing, which is why the type of kiln is critical.

The Power of Combustion

Gas kilns generate heat through active combustion—burning natural gas or propane. This process inherently involves mixing fuel and air, giving the artist direct control over the atmosphere.

The Role of the Damper

The key tool for creating reduction is the damper, which is essentially a plate that can be adjusted to block the kiln's flue or chimney. Closing the damper restricts the exit of exhaust and limits the entry of fresh air (oxygen).

By carefully balancing the gas pressure (fuel) with the damper setting (air), a potter can create and sustain a reduction atmosphere at specific temperatures.

Why Electric Kilns Are Unsuitable

Electric kilns heat with radiant elements, not a flame. There is no combustion to manipulate. The atmosphere is naturally oxygen-rich (oxidation).

Attempting to create reduction by introducing combustible materials (like wood or gas) into an electric kiln is extremely dangerous. It will destroy the expensive heating elements and poses a significant fire and electrocution risk.

Understanding the Trade-offs

While it produces stunning results, reduction is a more complex and less predictable process than oxidation.

Embracing Variability

Reduction firings are dynamic and sensitive to subtle changes in airflow and fuel pressure. The results can vary significantly from one firing to the next, and even within different parts of the same kiln. This "happy accident" quality is a celebrated feature for many, but a challenge for those seeking perfect consistency.

Impact on Clay Bodies

The reduction atmosphere affects not only the glaze but also the clay body underneath. Iron present in the clay will also be reduced, often resulting in a darker, toastier, or speckled appearance that adds depth and warmth to the final piece.

Safety and Skill Requirements

Because reduction involves incomplete combustion, it produces carbon monoxide and soot. A properly designed and well-ventilated kiln space is absolutely essential for safety. Mastering reduction requires practice, patience, and a deep understanding of your specific kiln.

Making the Right Choice for Your Goal

Your desired aesthetic should guide your choice of firing method. There is no "better" atmosphere, only the one that achieves your specific artistic vision.

- If your primary focus is predictability, ease of use, and bright, stable colors: Oxidation firing in an electric kiln is the most reliable and accessible path.

- If your primary focus is achieving earthy, deep, and classic glaze effects like copper reds and celadons: Reduction firing in a gas kiln is essential to create the necessary chemical reactions.

- If your primary focus is embracing variability and allowing the kiln's atmosphere to be an active participant in the final look: The dynamic and sometimes unpredictable nature of reduction offers limitless artistic possibilities.

Ultimately, choosing a firing method is choosing your palette of potential outcomes.

Summary Table:

| Aspect | Description |

|---|---|

| Reduction Firing | Intentional oxygen-starved atmosphere in kiln for chemical changes in glazes and clay. |

| Kiln Type | Fuel-burning kilns, especially gas kilns, support reduction via damper control. |

| Key Effects | Produces colors like copper reds, crimsons, purples, and celadon greens/blues. |

| Safety Note | Generates carbon monoxide; requires proper ventilation and skill to manage risks. |

Ready to achieve stunning ceramic effects with precise kiln control? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for artists, potters, and laboratories. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, with strong deep customization capabilities to meet your unique experimental and artistic needs. Contact us today to enhance your firing processes and unlock new creative possibilities!

Visual Guide

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

People Also Ask

- How does an inert atmosphere prevent oxidation? Shield Materials from Oxygen Damage

- What is nitrogen used for in a furnace? Prevent Oxidation and Control Heat Treatment Quality

- How does a chemically inert atmosphere function in a furnace? Prevent Oxidation and Ensure Material Purity

- What are the environmental benefits of using inert gases in furnaces? Reduce Waste and Emissions for a Greener Process

- What are the benefits of inert atmosphere heat treating? Prevent Oxidation and Preserve Material Integrity