At its core, a vacuum heat treatment furnace is a specialized piece of thermal equipment that heats materials to precise temperatures inside a vacuum-sealed chamber. It achieves this by fundamentally combining two distinct fields: vacuum technology and heat treatment technology. This fusion allows for metallurgical processes to occur in an environment free from air and other atmospheric gases, preventing unwanted chemical reactions like oxidation.

The essential purpose of a vacuum furnace is not just to heat material, but to control the environment in which it is heated. By removing the atmosphere, it enables a level of purity, precision, and process control that is impossible to achieve with conventional open-air or atmosphere furnaces.

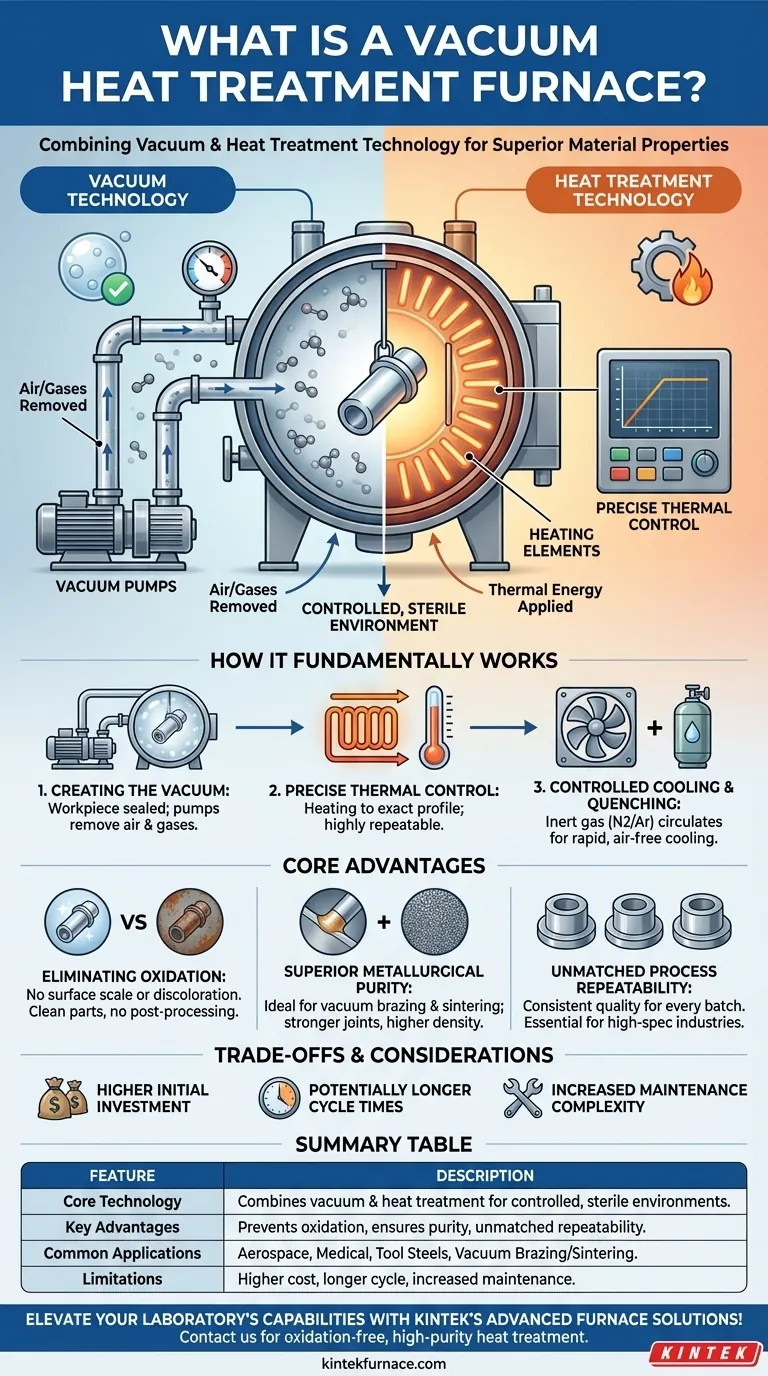

How a Vacuum Furnace Fundamentally Works

A vacuum furnace operates on the principle of creating a controlled, sterile environment before applying thermal energy. This is managed by several interconnected systems working in concert.

Creating the Vacuum

The process begins by placing the workpiece inside the vacuum chamber and sealing it. A system of powerful vacuum pumps then activates to remove the air and other gaseous molecules from the chamber, creating a low-pressure environment.

This step is critical because it eliminates oxygen, water vapor, and other potential contaminants that would otherwise react with the material at high temperatures.

Precise Thermal Control

Once the desired vacuum level is reached, the heating elements inside the furnace energize. A sophisticated temperature control system precisely manages the heating rate, holding temperature, and duration of the cycle.

This ensures the material undergoes the exact thermal profile required for the intended metallurgical transformation, providing highly repeatable and stable results.

Controlled Cooling and Quenching

After the heating cycle is complete, the material must be cooled. Vacuum furnaces often include advanced cooling systems that can circulate inert gases like nitrogen or argon at high pressure to cool the workpiece rapidly.

This process, known as gas quenching, allows for hardening and other transformations without ever exposing the part to open air.

The Core Advantage: Why Operate in a Vacuum?

Using a vacuum as the processing environment provides distinct advantages over traditional atmosphere-based heat treatment, directly impacting the quality and properties of the final product.

Eliminating Oxidation and Contamination

The most significant benefit is the prevention of oxidation. Without oxygen, materials do not form a layer of scale or discoloration on their surface, even at extreme temperatures. This results in bright, clean parts straight out of the furnace.

This eliminates the need for post-processing steps like sandblasting or chemical cleaning, saving both time and cost.

Achieving Superior Metallurgical Purity

A vacuum environment is inherently pure. This makes it ideal for processes like vacuum brazing, where strong, clean joints can be formed without the use of corrosive flux.

Similarly, in sintering applications, the vacuum prevents trapped gases, leading to higher-density components with minimal porosity and superior mechanical strength.

Unmatched Process Repeatability

Because the furnace environment is meticulously controlled—from the vacuum level to the thermal profile—the entire process is highly predictable and repeatable. Every batch can be processed under identical conditions, ensuring consistent quality.

This is critical for high-specification industries like aerospace, medical, and tool manufacturing, where part-to-part consistency is non-negotiable.

Understanding the Trade-offs

While powerful, vacuum heat treatment is not the universal solution for every application. Understanding its limitations is key to making an informed decision.

Higher Initial Investment

Vacuum furnaces are complex machines involving sophisticated pumps, seals, and control systems. This results in a significantly higher initial equipment cost compared to simpler atmospheric furnaces.

Potentially Longer Cycle Times

The need to pump the chamber down to a deep vacuum adds time to the beginning of every cycle. For very high-volume, low-margin parts, this can impact overall throughput.

Increased Maintenance Complexity

The vacuum pumps, chamber seals, and instrumentation require specialized knowledge and a rigorous maintenance schedule to ensure they operate correctly and prevent leaks, which can compromise the entire process.

Making the Right Choice for Your Application

Selecting the right thermal processing technology depends entirely on your material, your quality requirements, and your production goals.

- If your primary focus is part cleanliness and superior joint quality (e.g., medical implants, aerospace brazing): A vacuum furnace is the definitive choice for its unmatched purity.

- If your primary focus is process repeatability for high-performance alloys (e.g., tool steels, superalloys): The precise control offered by a vacuum furnace is essential to achieve the required metallurgical properties.

- If your primary focus is high-volume, general-purpose heat treatment where surface finish is less critical: A traditional atmosphere furnace may be a more cost-effective solution.

Ultimately, choosing a vacuum furnace is an investment in environmental control to achieve a higher class of material quality.

Summary Table:

| Feature | Description |

|---|---|

| Core Technology | Combines vacuum technology and heat treatment for controlled, sterile environments. |

| Key Advantages | Prevents oxidation, ensures metallurgical purity, and offers unmatched process repeatability. |

| Common Applications | Aerospace components, medical implants, tool steels, and vacuum brazing/sintering. |

| Limitations | Higher initial cost, longer cycle times, and increased maintenance complexity. |

Elevate your laboratory's capabilities with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems tailored for industries like aerospace, medical, and tool manufacturing. Benefit from our deep customization to precisely meet your unique experimental needs for oxidation-free, high-purity heat treatment. Contact us today to discuss how our solutions can enhance your process efficiency and product quality!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What is a vacuum furnace used for? Achieve Purity and Precision in High-Temp Processing

- How does vacuum heat treatment improve mechanical properties of metals? Enhance Strength and Durability

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- Where are vacuum furnaces used? Critical Applications in Aerospace, Medical, and Electronics

- What does a vacuum furnace do? Achieve Superior Material Processing in a Pure Environment