At its core, a continuous vacuum furnace is an industrial assembly line for heat treatment, processing materials non-stop without interrupting the vacuum environment. Unlike traditional batch furnaces that must be stopped, cooled, and restarted for each load, a continuous furnace allows a constant flow of parts through various heating and cooling zones, making it ideal for high-volume, consistent production.

The fundamental difference isn't just the furnace, but the entire production philosophy. A continuous vacuum furnace prioritizes high-volume throughput and absolute process uniformity, while a batch furnace prioritizes flexibility for varied, smaller-scale jobs.

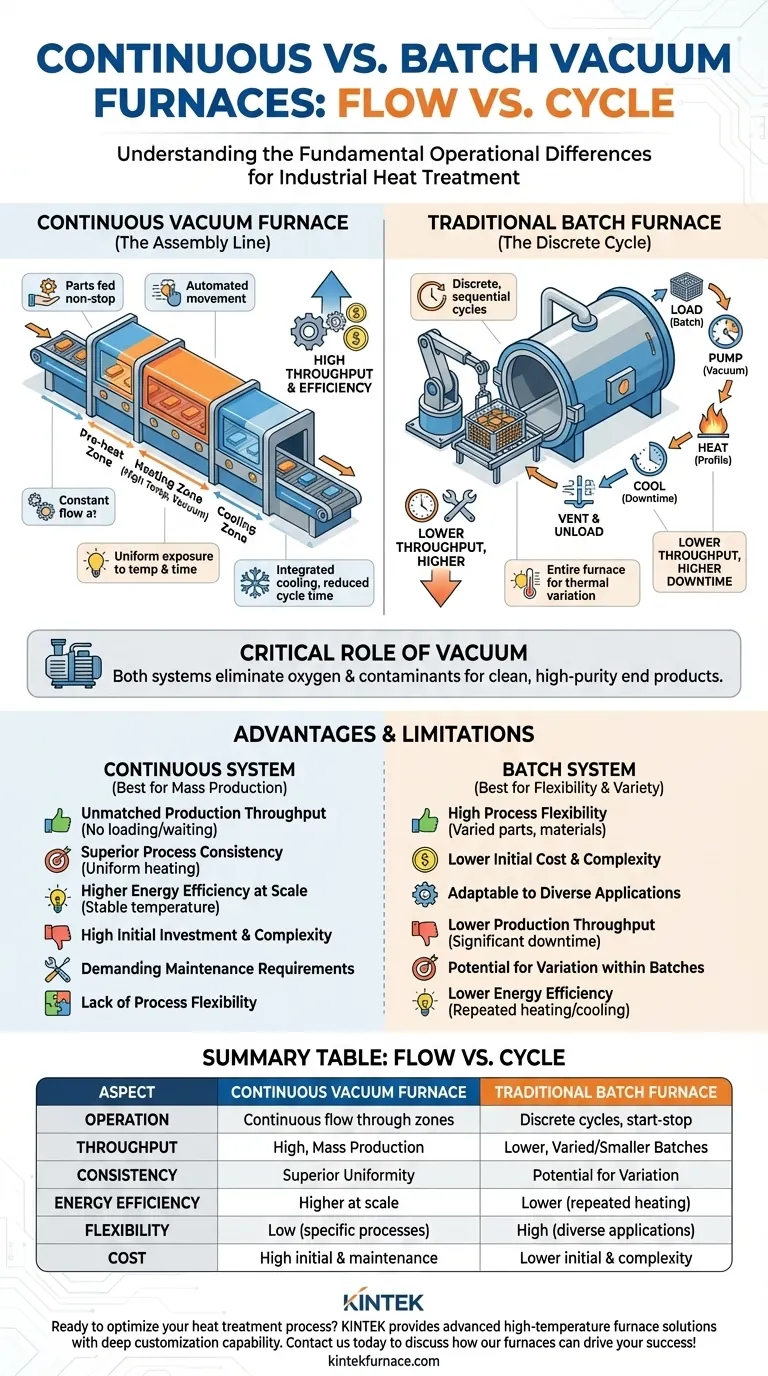

The Core Operational Difference: Flow vs. Cycle

The choice between a continuous and batch furnace comes down to how you need to process your materials. Their operational models are fundamentally different.

How a Continuous Vacuum Furnace Works

A continuous vacuum furnace operates like a highly controlled, automated production line. Parts are fed into the system, move through one or more sealed chambers, and exit without ever breaking the vacuum.

The process is fully automatic, with materials moving at a constant, calculated speed. This ensures every single part is exposed to the exact same temperature profile for the exact same amount of time, delivering exceptional consistency. They often include integrated cooling sections to reduce overall cycle time from start to finish.

How a Traditional Batch Furnace Works

A batch furnace operates in discrete, sequential cycles. An entire "batch" of parts is loaded into the chamber, which is then sealed and has the air pumped out to create a vacuum.

The furnace then runs a programmed heating and cooling profile. Once the cycle is complete, the chamber is vented, opened, and the finished parts are unloaded. The entire furnace must often cool before it can be reloaded, introducing significant downtime between jobs.

The Critical Role of the Vacuum

Both furnace types use a vacuum to achieve a specific goal: eliminating oxygen and other atmospheric contaminants. By removing air, you prevent oxidation on the material's surface, resulting in cleaner, higher-purity end products with superior mechanical properties.

Advantages of a Continuous System

For the right application, a continuous vacuum furnace offers significant advantages over a batch process.

Unmatched Production Throughput

By eliminating the start-stop nature of batch processing, continuous furnaces achieve a much higher output. There is no downtime for loading, unloading, or waiting for the furnace to heat up and cool down between cycles.

Superior Process Consistency

In a batch furnace, parts on the outside of the load can experience slightly different heating and cooling rates than parts in the center. A continuous furnace eliminates this "perimeter effect" by heating each part individually as it moves through the chamber, guaranteeing exceptional uniformity across a production run of thousands of parts.

Higher Energy Efficiency at Scale

While the furnace itself is complex, it avoids the massive energy waste of repeatedly heating and cooling the entire thermal mass of a batch furnace chamber. By maintaining a stable operating temperature, the energy cost per part produced is significantly lower in a high-volume scenario.

Understanding the Trade-offs and Limitations

The high throughput of a continuous system comes with significant trade-offs that make it unsuitable for many applications.

High Initial Investment and Complexity

Continuous vacuum furnaces are sophisticated, multi-chamber electromechanical systems. Their design, installation, and initial setup are far more complex and carry a much higher capital cost than a standard batch furnace.

Demanding Maintenance Requirements

More moving parts and automation mean more potential points of failure. These systems require a rigorous and more frequent maintenance schedule to ensure reliable, uninterrupted operation.

Lack of Process Flexibility

A continuous furnace is typically optimized for a specific part and a single, repeatable thermal process. It is highly inefficient for job shops that handle a wide variety of parts, materials, or small-volume orders, which is where batch furnaces excel.

Making the Right Choice for Your Operation

Choosing the correct furnace technology is a critical decision that directly impacts your operational efficiency, cost structure, and product quality. The right answer depends entirely on your production goals.

- If your primary focus is mass production and process consistency: A continuous vacuum furnace is the definitive choice for high-volume, repeatable manufacturing where uniformity is paramount.

- If your primary focus is flexibility for varied parts or smaller runs: A batch furnace provides the versatility and lower barrier to entry needed for job-shop environments or research and development.

- If your primary focus is minimizing initial capital investment: A batch furnace is a significantly more affordable and less complex solution to acquire and install.

Understanding this fundamental distinction between flow-based and cycle-based processing empowers you to align your equipment strategy with your core business objectives.

Summary Table:

| Aspect | Continuous Vacuum Furnace | Traditional Batch Furnace |

|---|---|---|

| Operation | Continuous flow through sealed zones | Discrete cycles with start-stop loading |

| Throughput | High, ideal for mass production | Lower, suited for varied, smaller batches |

| Consistency | Superior uniformity across all parts | Potential for variation within batches |

| Energy Efficiency | Higher at scale due to stable operation | Lower due to repeated heating/cooling |

| Flexibility | Low, optimized for specific processes | High, adaptable to diverse applications |

| Cost | High initial investment and maintenance | Lower initial cost and complexity |

Ready to optimize your heat treatment process? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Whether you need high-volume consistency or flexible batch processing, we can tailor solutions to enhance your efficiency and product quality. Contact us today to discuss how our furnaces can drive your success!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- What is the heat treatment in a vacuum furnace? Achieve Superior Metallurgical Properties

- What does a vacuum furnace do? Achieve Superior Material Processing in a Pure Environment

- Why use a vacuum furnace? Achieve Unparalleled Material Purity and Process Control

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion