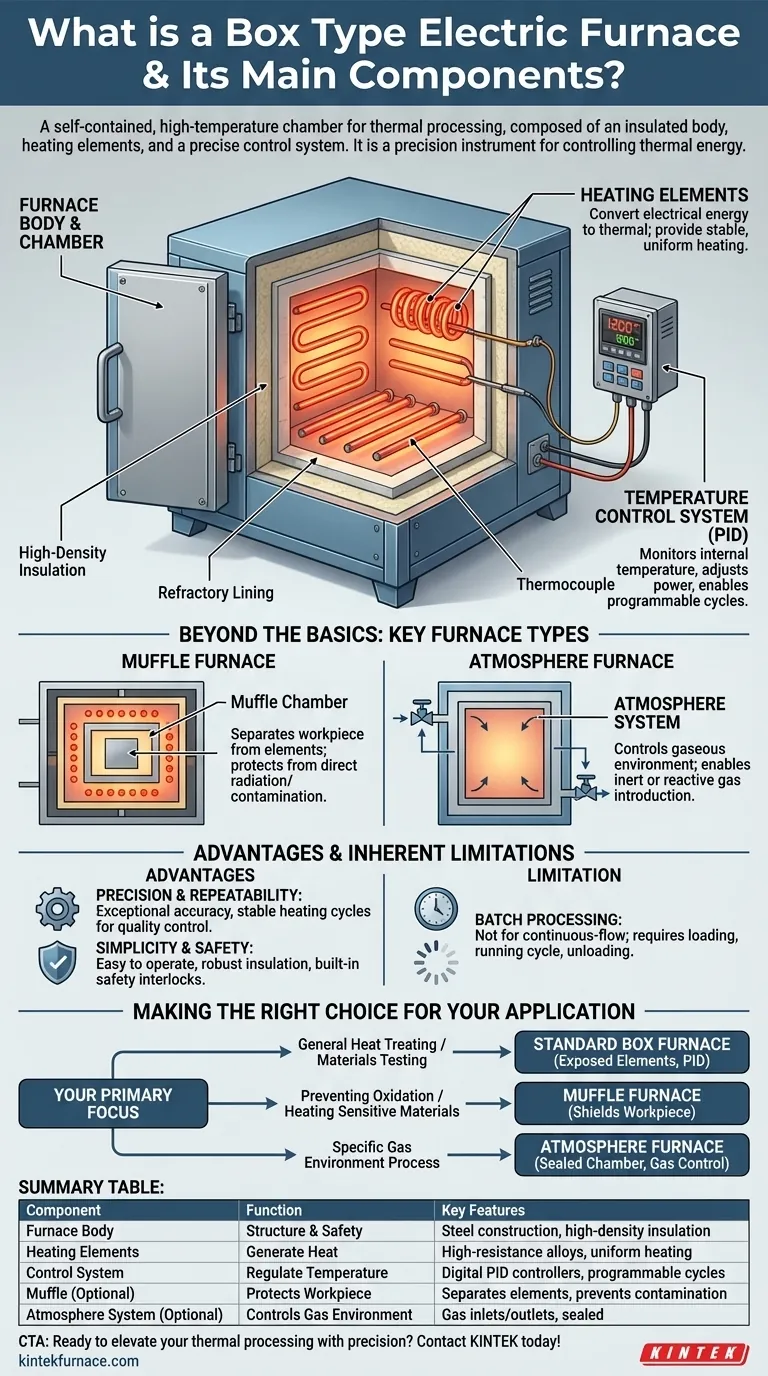

In essence, a box type electric furnace is a self-contained, high-temperature chamber used for a wide range of thermal processing applications, from laboratory research to industrial manufacturing. Often called a muffle furnace, its design is defined by a simple, accessible box-like structure. The system's core is composed of an insulated furnace body, internal heating elements, and a precise temperature control system.

A box furnace is more than just a heating cabinet; it is a precision instrument for controlling thermal energy. Understanding how its core components—the body, heating elements, and controller—work in concert is key to leveraging it for reliable and repeatable results.

Deconstructing the Core Components

A box furnace's reliability stems from the simple and robust design of its primary systems. Each component has a distinct role in achieving a stable, uniform, and controllable heating environment.

The Furnace Body and Chamber

The furnace body, or cabinet, is the external structure that provides physical support and operator safety. It is typically constructed from steel and contains a thick layer of high-density insulation.

This insulation is critical for two reasons: it minimizes heat loss to ensure energy efficiency and keeps the external surface at a safe temperature for personnel.

Inside the body is the furnace chamber, where workpieces are placed. This chamber is lined with refractory materials capable of withstanding extreme temperatures.

The Heating Elements

Heating elements are the heart of the furnace, responsible for converting electrical energy into thermal energy. They are strategically placed within the chamber to provide stable and uniform heating.

The most common type of element is a high-resistance wire or rod, often made from specialized alloys. The goal is to heat the entire chamber volume evenly, avoiding hot or cold spots that could compromise the workpiece.

The Temperature Control System

This is the furnace's brain. The control system continuously monitors the internal temperature via a thermocouple and adjusts the power sent to the heating elements to maintain a setpoint.

Modern furnaces use sophisticated digital controllers, often with PID (Proportional-Integral-Derivative) logic, to regulate temperature with exceptional accuracy. These systems allow for programmable heating cycles, enabling automatic control of heating rates, soak times, and cooling profiles.

Beyond the Basics: Key Furnace Types

While the core components are universal, important variations exist that tailor the furnace for specific tasks. The most significant distinction is how the furnace atmosphere is managed.

Muffle vs. Open Element Furnaces

In some designs, the heating elements are exposed directly within the main chamber. However, a true muffle furnace features an inner chamber, or "muffle," that separates the workpiece from the heating elements.

This design protects the workpiece from direct radiation and any potential contamination from the elements, which is critical for sensitive processes.

Atmosphere Furnaces

A box-type atmosphere furnace is a more advanced variant that allows the user to control the gaseous environment inside the chamber.

These systems include gas inlets and outlets, enabling the introduction of inert gases (like argon or nitrogen) to prevent oxidation or reactive gases for specific surface treatment processes. They require superior seals and a dedicated gas management system.

Understanding the Advantages and Trade-offs

Box furnaces are widely used because they offer a compelling balance of performance and usability, but it's important to recognize their inherent design characteristics.

Advantage: Precision and Repeatability

Thanks to modern digital controllers, box furnaces deliver exceptional temperature accuracy and stability. The ability to program and automate heating cycles ensures that processes are highly repeatable, which is essential for quality control in both research and production.

Advantage: Simplicity and Safety

The integrated, self-contained design makes box furnaces relatively simple to operate. The robust insulation and built-in safety interlocks, such as automatic shut-offs if a door is opened, provide a high degree of operational safety.

Inherent Limitation: Batch Processing

By their nature, box furnaces are designed for batch processing. Materials are loaded, the thermal cycle is run, and the materials are unloaded. They are not suited for continuous-flow manufacturing operations, which require tunnel or conveyor furnaces.

Making the Right Choice for Your Application

Selecting the correct furnace configuration depends entirely on the process you need to perform.

- If your primary focus is general heat treating or materials testing: A standard box furnace with exposed elements and a reliable PID controller is your workhorse.

- If your primary focus is preventing oxidation or heating sensitive materials: You must specify a muffle furnace to shield the workpiece from direct element radiation.

- If your primary focus is performing a process in a specific gas environment: An atmosphere furnace with a sealed chamber and a dedicated gas control system is non-negotiable.

Ultimately, choosing the right furnace begins with a clear understanding of your specific thermal processing requirements.

Summary Table:

| Component | Function | Key Features |

|---|---|---|

| Furnace Body | Provides structure and safety | Steel construction, high-density insulation |

| Heating Elements | Generate heat | High-resistance alloys, uniform heating |

| Temperature Control System | Regulates temperature | Digital PID controllers, programmable cycles |

| Muffle (Optional) | Protects workpiece | Separates elements from chamber, prevents contamination |

| Atmosphere System (Optional) | Controls gas environment | Gas inlets/outlets, seals for inert/reactive gases |

Ready to elevate your thermal processing with precision and reliability? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for diverse laboratories. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to meet your unique experimental needs. Don't settle for less—contact us today to discuss how we can optimize your lab's efficiency and results!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the primary use of a muffle furnace in the assembly of side-heated resistive gas sensors? Expert Annealing Guide

- How does a muffle furnace contribute to kaolin-modified biochar? Optimize Pyrolysis & Mineral Integration

- Why is a muffle furnace used to determine the ash content of biochar? Master Your Material Purity Analysis

- How do repeat sintering processes and specialized sintering molds address the technical challenges of manufacturing oversized flywheel rotor components? Expand Scale and Integrity

- What role does a muffle furnace play in the conversion of S-1@TiO2? Achieve Precision Calcination of Nanospheres