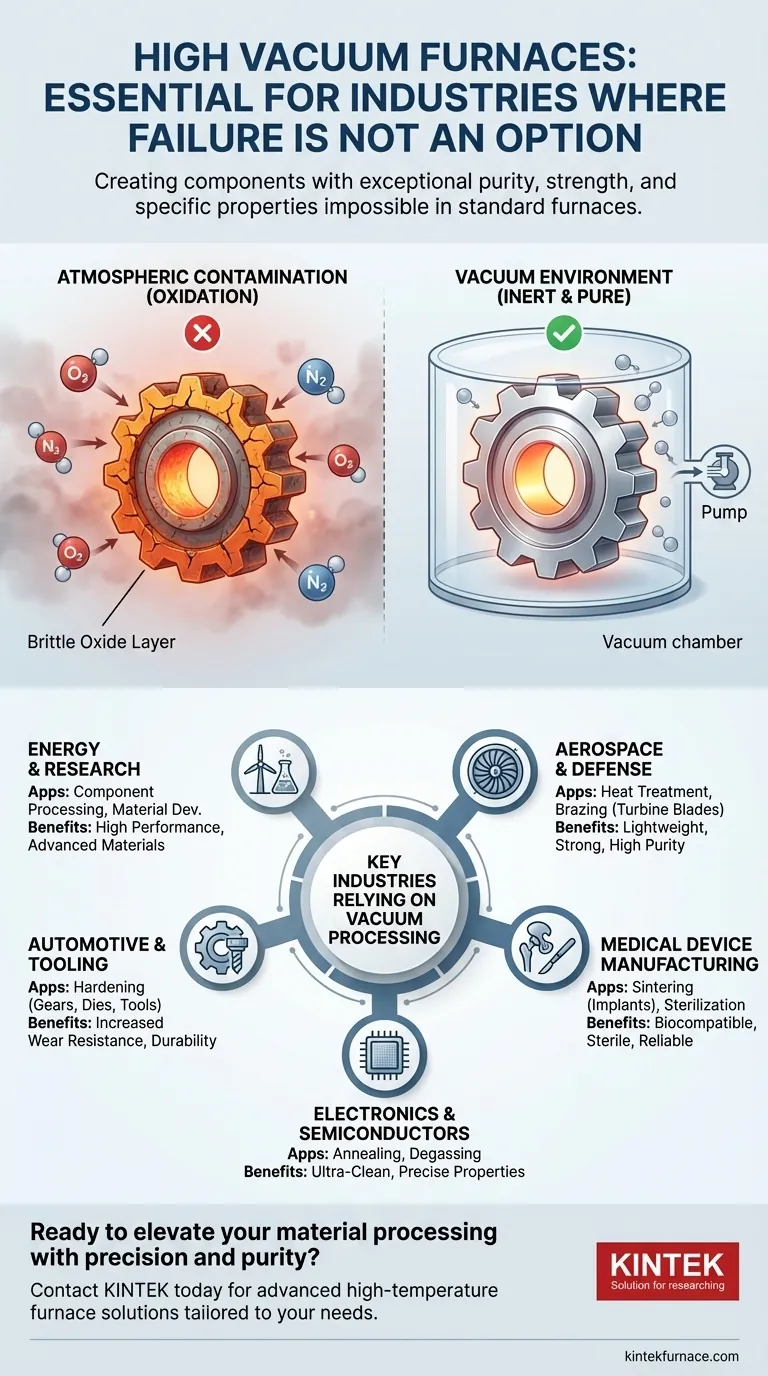

At their core, high vacuum furnaces are indispensable tools for industries where material failure is not an option. The most prominent users are found in aerospace, medical device manufacturing, and advanced electronics, with significant applications in the automotive, energy, and high-performance tooling sectors as well. These industries rely on vacuum processing to create components with exceptional purity, strength, and specific microstructural properties that are impossible to achieve in a standard atmospheric furnace.

The fundamental reason these industries use high vacuum furnaces is to control a material's environment at extreme temperatures. By removing atmospheric gases like oxygen, the furnace prevents contamination and oxidation, enabling the creation of stronger, purer, and more reliable high-performance components.

The Core Problem: Why a Vacuum is Essential

High-temperature processing is transformative, but it also makes materials highly reactive. A vacuum furnace is designed to solve one critical problem: contamination.

Eliminating Atmospheric Contamination

When metals are heated to high temperatures, they readily react with gases in the air, especially oxygen and nitrogen. This reaction, known as oxidation, forms a brittle oxide layer on the surface, compromising the material's strength, fatigue life, and chemical purity.

A high vacuum furnace pumps out these reactive gases, creating an inert environment. This ensures that the material is only exposed to heat, allowing for precise control over the final product's properties without unwanted chemical reactions.

Achieving Unmatched Purity and Performance

For critical applications like a jet engine turbine blade or a surgical implant, material integrity is paramount. The vacuum environment preserves the precise chemical composition of advanced alloys.

This purity prevents internal defects and ensures the material achieves its maximum theoretical strength, durability, and performance characteristics. Processes like degassing, which are only possible in a vacuum, actively remove trapped gases from within the material itself.

Key Industrial Applications

The need for pure, strong, and reliable materials drives the adoption of vacuum furnaces across several high-stakes industries.

Aerospace and Defense

This sector demands materials that can withstand extreme stress, vibration, and temperatures. Vacuum furnaces are used for the heat treatment of critical engine components and the brazing of complex assemblies like turbine blades. The result is parts that are both lightweight and incredibly strong.

Medical Device Manufacturing

When a device is implanted in the human body, biocompatibility and purity are non-negotiable. Vacuum furnaces are used to sinter titanium powders into hip implants and to create surgical instruments that are sterile and free from any contaminants that could cause an adverse reaction.

Electronics and Semiconductors

The manufacturing of semiconductors requires an ultra-clean environment. Even microscopic contamination can ruin a silicon wafer. High vacuum furnaces are used for processes like annealing and degassing to ensure the electrical properties of the semiconductor materials are perfect.

Automotive and Tooling

In high-performance automotive and industrial tooling, durability is key. Vacuum furnaces are used to harden gears, dies, and cutting tools, significantly increasing their wear resistance and lifespan. This process creates parts that can withstand immense pressure and friction.

Energy and Research

The energy sector uses vacuum-processed components in power generation turbines and other high-stress equipment. Furthermore, research and development labs rely on vacuum furnaces to experiment with and develop the next generation of advanced materials for all the industries mentioned above.

Understanding the Trade-offs

While incredibly powerful, vacuum heat treatment is not a universal solution. It is a specialized process chosen for specific technical requirements.

Higher Cost and Complexity

Vacuum furnaces are significantly more expensive to build and operate than standard atmospheric furnaces. They require complex pumping systems, sophisticated controls, and longer cycle times to pump down the chamber to the required vacuum level.

Slower Throughput

The need to create a vacuum before the heating cycle can begin, and often the need for controlled cooling afterward, means that total process time is longer. For simple parts where surface oxidation is not a critical concern, a faster, less expensive atmospheric process may be sufficient.

Maintenance and Expertise

Operating a vacuum furnace requires a higher level of technical expertise. Maintaining the vacuum pumps, seals, and chamber integrity is a constant and critical task. A small leak can compromise an entire batch of expensive components.

How to Apply This to Your Goal

Your choice of thermal processing should be driven by the final requirements of your component.

- If your primary focus is joining complex, high-stress components: Vacuum brazing provides clean, strong, and flux-free joints that are essential for aerospace and medical applications.

- If your primary focus is maximizing the hardness and wear resistance of steel parts: Vacuum heat treating is the standard for creating high-performance tools, dies, and gears with superior durability.

- If your primary focus is creating solid parts from powder materials: Vacuum sintering is critical for producing pure, high-density medical implants and advanced ceramic components.

- If your primary focus is achieving absolute material purity: A vacuum environment is the only way to perform processes like degassing and create contamination-free components for electronics.

Ultimately, investing in vacuum furnace technology is a decision to prioritize material integrity above all else.

Summary Table:

| Industry | Key Applications | Benefits |

|---|---|---|

| Aerospace and Defense | Heat treatment, brazing of turbine blades | Exceptional strength, lightweight, high purity |

| Medical Device Manufacturing | Sintering of implants, instrument sterilization | Biocompatibility, no contamination, reliability |

| Electronics and Semiconductors | Annealing, degassing of wafers | Ultra-clean environment, precise electrical properties |

| Automotive and Tooling | Hardening of gears and tools | Increased wear resistance, durability |

| Energy and Research | Component processing, material development | High performance, innovation in advanced materials |

Ready to elevate your material processing with precision and purity? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for industries like aerospace, medical, and electronics. Our product line—including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—is complemented by strong deep customization capabilities to meet your unique experimental needs. Don't let contamination compromise your components—contact us today to discuss how our vacuum furnaces can enhance your product integrity and performance!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- What are the proper procedures for handling the furnace door and samples in a vacuum furnace? Ensure Process Integrity & Safety

- What are the benefits of vacuum heat treatment? Achieve Superior Metallurgical Control

- What is the vacuum heat treatment process? Achieve Superior Surface Quality and Material Performance