To properly use a Fast Slow Dental Sintering Furnace, you must follow strict procedural and safety precautions. Key actions include calibrating temperature sensors regularly, using separate crucibles and programs for different materials, precisely controlling heating and cooling rates to prevent cracking, and ensuring a safe lab environment with proper ventilation and protective gear.

The goal is not just to operate the furnace, but to master the thermal process. Each precaution is a critical step in controlling the material science of zirconia to produce restorations with predictable strength, aesthetics, and fit, while protecting your equipment and staff.

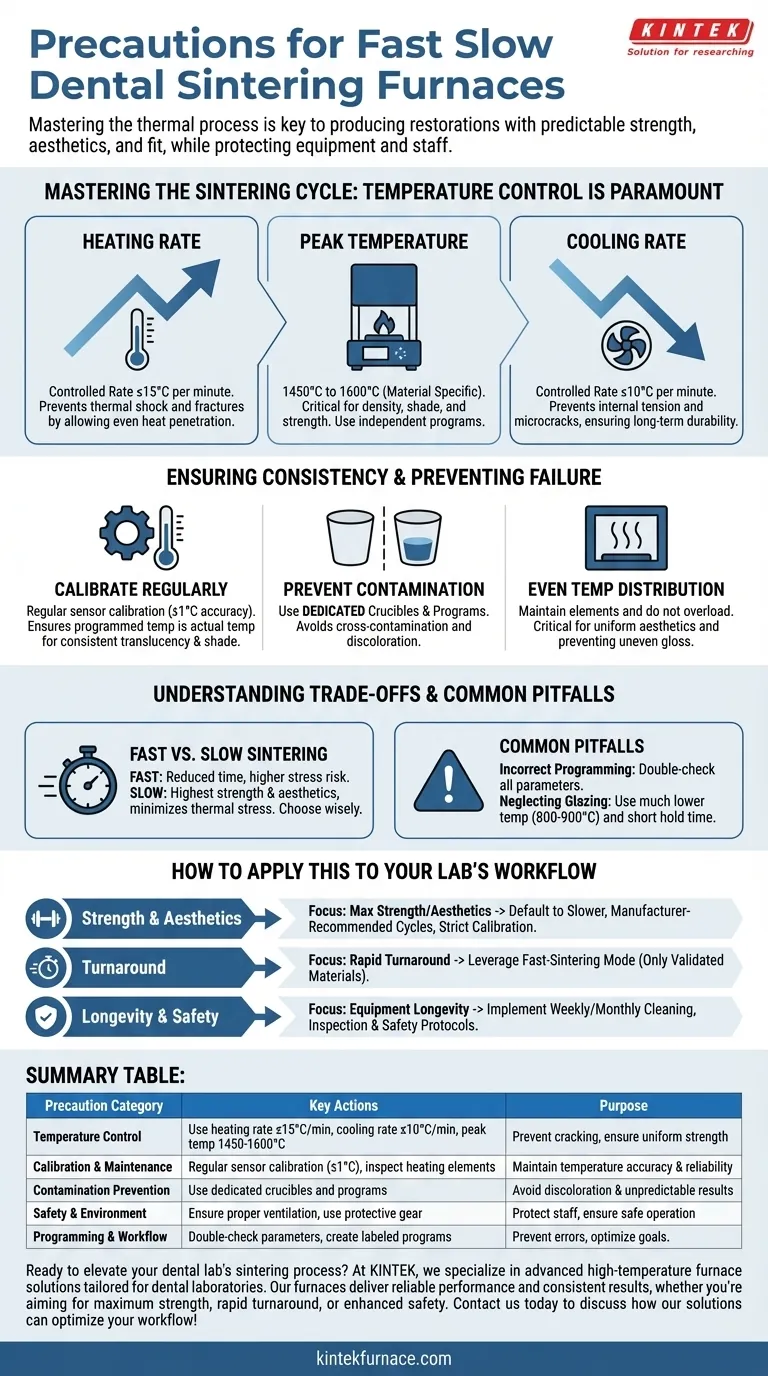

Mastering the Sintering Cycle: Temperature Control is Paramount

The quality of your final zirconia restoration is dictated by how precisely you manage temperature throughout the entire sintering cycle. Deviations can lead to failures that are both costly and time-consuming.

The Critical Role of the Heating Rate

Heating the zirconia too quickly induces thermal shock, which can cause fractures before the restoration even reaches its peak temperature.

A controlled heating rate of ≤15°C per minute is the standard recommendation. This slow ramp-up allows heat to penetrate the restoration evenly, preventing internal stresses that lead to cracks.

Adjusting Peak Temperature for Each Material

There is no universal sintering temperature. Different brands and types of zirconia (e.g., high-strength vs. high-translucency) have unique requirements specified by the manufacturer.

Peak temperatures typically range from 1450°C to 1600°C. Using the wrong peak temperature can result in poor density, incorrect shade, or reduced strength. Always create independent, clearly labeled programs for each material you use.

The Importance of a Controlled Cooling Rate

Just as important as heating is the cooling phase. Cooling too rapidly creates internal tension as the outer surface contracts faster than the core, leading to microcracks that compromise the restoration's long-term durability.

A slow, controlled cooling rate of ≤10°C per minute is crucial. This ensures the entire restoration cools uniformly, locking in its strength and preventing delayed fractures.

Ensuring Consistency and Preventing Failure

Repeatable, high-quality results depend on a well-maintained furnace and a contamination-free workflow.

Calibrate Your Furnace Regularly

Your furnace's display might read 1500°C, but if the actual temperature is 1480°C, your results will be inconsistent. Regular calibration of temperature sensors is non-negotiable.

This ensures the temperature accuracy you program is the temperature your restorations actually experience, which is vital for achieving the target translucency and shade. An accuracy of ±1°C is the benchmark for high-end furnaces.

Use Dedicated Crucibles and Programs

Zirconia materials are sensitive to chemical cross-contamination. Using the same sintering crucible for different materials can transfer trace elements, leading to discoloration or unpredictable results.

Always use dedicated, separate crucibles for different types of zirconia. Likewise, create and save independent sintering programs for each material, titling them clearly to prevent accidental selection of the wrong cycle.

Maintain Even Temperature Distribution

Inconsistent color or an uneven gloss across a bridge is often a sign of poor temperature distribution within the furnace chamber.

Ensure your heating elements are functioning correctly and that you are not overloading the furnace. This helps maintain a stable and uniform thermal environment, which is critical for aesthetic outcomes.

Understanding the Trade-offs and Common Pitfalls

A "Fast Slow" furnace offers flexibility, but this requires you to understand the implications of your choices.

Fast Sintering vs. Slow Sintering

The primary trade-off is time versus quality. Fast sintering cycles dramatically reduce turnaround time, which is a significant business advantage.

However, these accelerated cycles can create more internal stress and may not be suitable for all types of zirconia, particularly higher-translucency aesthetic materials. A slow, conventional cycle generally yields the highest possible strength and aesthetics by minimizing thermal stress.

The Risk of Incorrect Programming

A simple error in programming—like setting the wrong peak temperature or too fast a ramp rate—can ruin an entire batch of restorations.

Double-check every parameter before starting a cycle. The precision of these furnaces means they will execute your commands exactly, whether they are correct or not.

Neglecting Glazing Cycle Precautions

Glazing has its own set of rules. When applying a glaze, you must use a much lower temperature program, typically 800-900°C, with a short hold time of 5-10 minutes.

Exceeding this can cause the glaze to bubble, peel, or alter the surface texture, undoing your careful finishing work.

How to Apply This to Your Lab's Workflow

Your operational strategy should align with your lab's primary goals.

- If your primary focus is maximum strength and aesthetics: Always default to the slower, manufacturer-recommended sintering cycles and enforce a strict calibration schedule.

- If your primary focus is rapid turnaround time: Leverage the fast-sintering mode, but only for zirconia materials explicitly validated for such cycles by their manufacturer.

- If your primary focus is equipment longevity and safety: Implement a non-negotiable weekly and monthly checklist for cleaning, element inspection, and safety protocol reviews.

By treating these precautions as integral parts of your production process, you transform the furnace from a simple appliance into a reliable partner for producing exceptional dental restorations.

Summary Table:

| Precaution Category | Key Actions | Purpose |

|---|---|---|

| Temperature Control | Use heating rate ≤15°C/min, cooling rate ≤10°C/min, peak temp 1450-1600°C | Prevent cracking and ensure uniform strength and aesthetics |

| Calibration & Maintenance | Regular sensor calibration (±1°C accuracy), inspect heating elements | Maintain temperature accuracy and equipment reliability |

| Contamination Prevention | Use dedicated crucibles and programs for each material | Avoid discoloration and unpredictable results |

| Safety & Environment | Ensure proper ventilation, use protective gear, follow lab protocols | Protect staff and ensure safe operation |

| Programming & Workflow | Double-check parameters, create labeled programs, align with lab goals | Prevent errors and optimize for strength, speed, or longevity |

Ready to elevate your dental lab's sintering process? At KINTEK, we specialize in advanced high-temperature furnace solutions tailored for dental laboratories. Leveraging exceptional R&D and in-house manufacturing, our products—including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—are designed with strong deep customization capabilities to precisely meet your unique experimental needs. Whether you're aiming for maximum strength, rapid turnaround, or enhanced safety, KINTEK furnaces deliver reliable performance and consistent results. Contact us today to discuss how our solutions can optimize your sintering workflow and boost productivity!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Spark Plasma Sintering SPS Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- Why is using a universal setting for all materials in a dental furnace a mistake? Master Precision Sintering for Perfect Restorations

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations

- What aspects of a dental restoration are directly impacted by the choice of a dental sintering furnace? Ensure Fit, Strength & Longevity

- How often should dental furnaces be calibrated? Ensure Precision for Perfect Restorations

- Why is accurate temperature control important in dental furnaces? Ensure Perfect Restorations Every Time