At its core, a muffle furnace achieves rapid, uniform heating through the strategic placement of its heating elements and the design of its internal chamber. The most critical features are open coil heating elements positioned on multiple sides of the processing chamber. This design ensures fast, direct radiant heating, while advanced temperature controllers and thermally conductive chamber materials work in concert to distribute that heat evenly.

Fast heat-up and temperature uniformity are not the result of a single component. They are the outcome of an integrated system where heating element design, chamber construction, and sophisticated temperature controls work together to deliver precise and repeatable thermal processing.

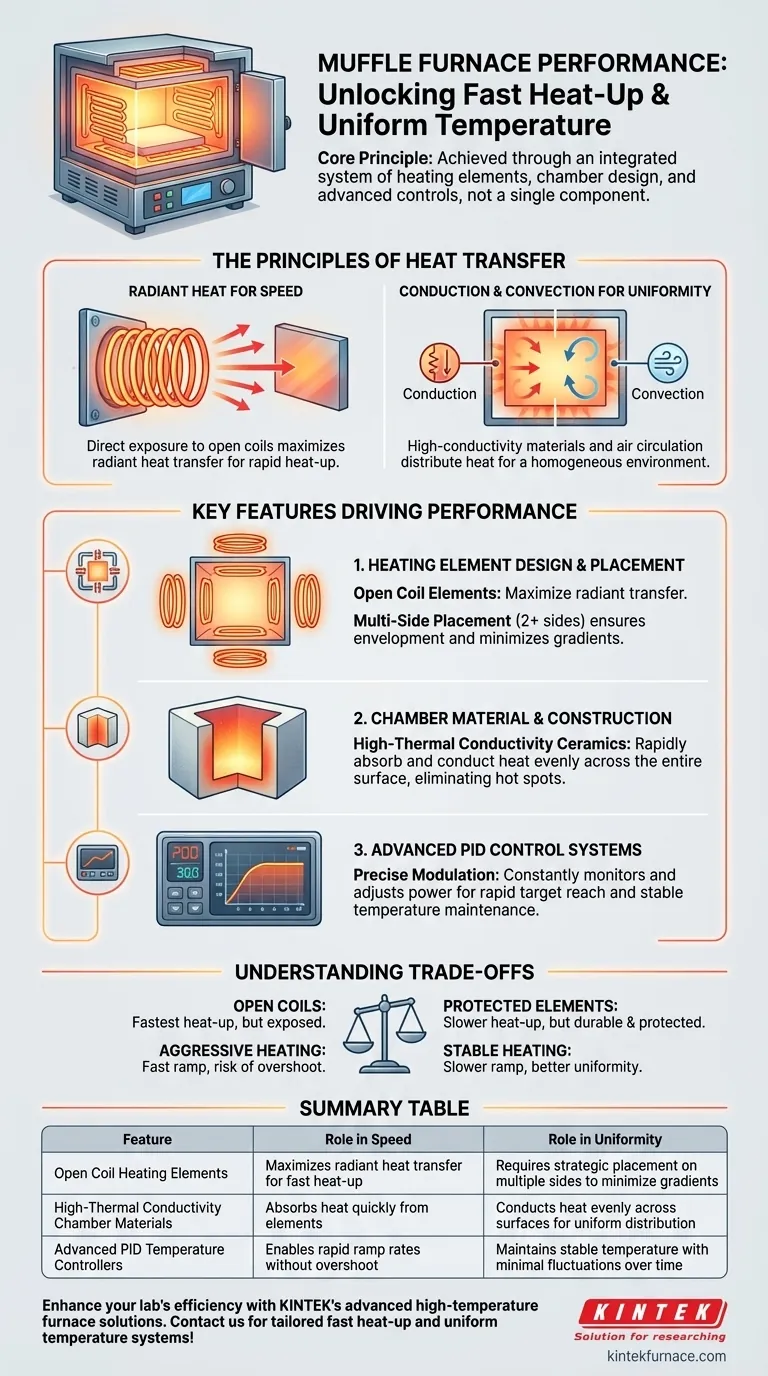

The Principles of Heat Transfer in a Furnace

To understand which features matter, we must first understand how a furnace heats a workpiece. The process relies on a combination of heat transfer methods, each contributing to either speed or uniformity.

The Role of Radiant Heat for Speed

Heating elements, typically made of high-resistance wire, generate intense heat when electricity passes through them. This energy travels through the empty space of the chamber as radiant heat.

Furnaces that expose the chamber directly to these elements, using an "open coil" design, transfer this energy very quickly. This direct exposure is the primary driver of a fast heat-up time.

The Role of Conduction and Convection for Uniformity

Once radiant heat strikes the chamber walls and the workpiece, it is absorbed. The heat then spreads through solid materials via conduction.

Materials with high thermal conductivity, such as dense ceramics, are essential for furnace chambers. They quickly absorb heat and spread it across their entire surface, helping to eliminate hot spots.

Simultaneously, the air or protective atmosphere inside the chamber heats up and circulates via convection, further distributing the temperature for a homogeneous environment.

Key Features Driving Performance

Based on these principles, three specific features are responsible for delivering both speed and uniformity.

Heating Element Design and Placement

The single most important feature for rapid heating is the use of open coil heating elements. By leaving the coils exposed, the furnace maximizes the rate of radiant heat transfer.

To ensure this heat is applied uniformly, these elements must be placed on at least two sides of the chamber. High-performance models often feature elements on three, four, or even five sides to fully envelop the workpiece in heat and minimize any temperature gradients.

Chamber Material and Construction

The interior chamber, or muffle, is not just a container; it's an active part of the heating system. It is constructed from highly heat-resistant materials, often advanced ceramics.

An effective chamber material possesses high thermal conductivity. This allows it to absorb heat quickly from the elements and conduct it evenly across its entire surface, creating a uniformly hot environment for the material being processed.

Advanced Temperature Control Systems

A powerful heating system is useless without precise control. Modern furnaces use fully programmable digital controllers (often PID controllers) that constantly monitor the chamber temperature via a thermocouple.

This controller modulates the power sent to the heating elements with extreme precision. It ensures the furnace reaches the target temperature quickly without significant "overshoot" and maintains that temperature with minimal fluctuation, which is critical for uniformity over time.

Understanding the Trade-offs

Selecting a furnace requires balancing competing priorities. The ideal features for speed are not always the ideal features for every application.

Open Coils vs. Protected Elements

While open coil elements provide the fastest heat-up, they are also more exposed to physical damage and potential contamination from outgassing samples.

Some furnace designs embed the heating elements within the ceramic insulation. This protects the elements and can extend their life, but it slows heat transfer, resulting in longer heat-up times.

Aggressive Heating vs. Stability

A "fully programmable" controller allows you to set a very fast heating rate. However, an overly aggressive rate can cause the temperature to exceed the setpoint before the controller can stabilize it.

Achieving uniformity requires giving the system time for conduction and convection to even out the temperature. The most uniform results often come from a controlled, slightly slower ramp rate.

Chamber Size and Load

Performance specifications are always dependent on context. A small, empty furnace will heat up much faster than a large furnace packed with a dense workload.

The mass of the items you place in the furnace will act as a heat sink, increasing the time required to reach both the setpoint and thermal equilibrium (uniformity).

How to Apply This to Your Goal

Your specific application determines which features to prioritize.

- If your primary focus is maximum throughput and speed: Prioritize a furnace with open coil heating elements on three or more sides of the chamber.

- If your primary focus is absolute precision and repeatability: Scrutinize the specifications of the digital temperature controller and verify the chamber is built from a single-piece, high-conductivity ceramic.

- If your primary focus is long-term durability with corrosive materials: Consider a furnace with embedded or protected heating elements, accepting the trade-off of a slower heat-up cycle.

By understanding how these core features function as a system, you can confidently select and operate a furnace that delivers the performance your work demands.

Summary Table:

| Feature | Role in Speed | Role in Uniformity |

|---|---|---|

| Open Coil Heating Elements | Maximizes radiant heat transfer for fast heat-up | Requires strategic placement on multiple sides to minimize gradients |

| High-Thermal Conductivity Chamber Materials | Absorbs heat quickly from elements | Conducts heat evenly across surfaces for uniform distribution |

| Advanced PID Temperature Controllers | Enables rapid ramp rates without overshoot | Maintains stable temperature with minimal fluctuations over time |

Ready to enhance your lab's efficiency with a high-performance muffle furnace? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental requirements. Contact us today to discuss how our tailored solutions can deliver fast heat-up and uniform temperature for your specific applications!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation