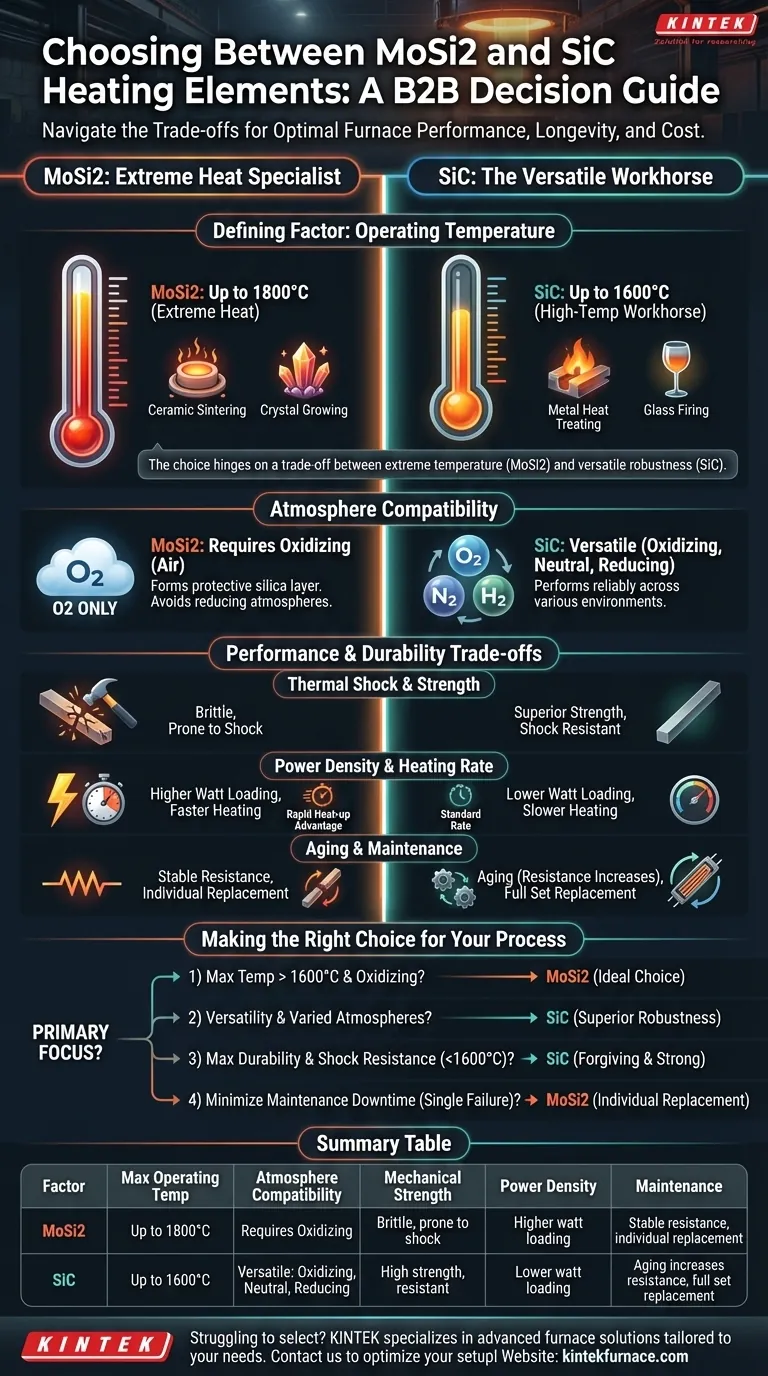

Choosing between MoSi2 and SiC heating elements is a critical decision that directly impacts furnace performance, longevity, and operational cost. While both are premier materials for high-temperature applications, their ideal use cases are distinct. The primary factors are maximum operating temperature and atmospheric conditions, with MoSi2 excelling at extreme temperatures (up to 1800°C) in oxidizing environments, and SiC offering greater versatility and mechanical robustness at slightly lower temperatures (up to 1600°C).

The choice is not about which material is universally "better," but which is precisely suited to your specific process. The decision hinges on a trade-off between the extreme temperature capability of Molybdenum Disilicide (MoSi2) and the versatile, mechanically robust nature of Silicon Carbide (SiC).

The Defining Factor: Operating Temperature

The first and most important filter in your decision is the maximum temperature your process requires.

MoSi2: For Extreme Heat (up to 1800°C)

Molybdenum Disilicide elements are the standard for applications that demand operating temperatures from approximately 1550°C up to 1800°C (3272°F).

Their ability to perform at these temperatures is due to the formation of a protective, self-healing layer of silica (SiO2) glass on their surface.

This makes MoSi2 the default choice for specialized processes like sintering advanced ceramics, growing crystals, and high-temperature materials research.

SiC: The High-Temp Workhorse (up to 1600°C)

Silicon Carbide elements are exceptionally reliable for the majority of high-temperature applications, with a maximum operating temperature of around 1600°C (2912°F).

They are the proven, go-to element for heat treating metals, firing glass and ceramics, and in furnaces for electronic component manufacturing. For any process that operates consistently below 1550°C, SiC is often the more practical and robust option.

Atmosphere Compatibility: Where Each Element Thrives

The furnace atmosphere is the second critical factor, as it determines the chemical stability and lifespan of the element.

MoSi2's Reliance on Oxygen

MoSi2 elements require an oxidizing atmosphere (like air) to function correctly. The protective silica layer that allows for high-temperature operation can only form and replenish itself in the presence of oxygen.

Using MoSi2 in reducing or neutral atmospheres can lead to rapid degradation and element failure.

SiC's Versatility Across Environments

SiC is significantly more versatile. It performs reliably in oxidizing, neutral, and many reducing atmospheres.

This robustness makes SiC a much safer and more flexible choice for applications where the furnace atmosphere may vary or for processes like nitriding that explicitly exclude oxygen.

Understanding the Trade-offs: Performance and Durability

Beyond temperature and atmosphere, the operational characteristics of your furnace will favor one material over the other.

Thermal Shock and Mechanical Strength

SiC possesses superior mechanical strength and resistance to thermal shock compared to MoSi2. It can withstand faster heating and cooling cycles without fracturing.

MoSi2 is more brittle, especially at lower temperatures, and is more susceptible to damage from physical impact or rapid temperature changes.

Power Density and Heating Rate

MoSi2 elements typically allow for a higher watt loading, or power density. This means they can often heat a furnace chamber more rapidly than SiC elements of a similar size.

If rapid heat-up is a critical process requirement in an oxidizing atmosphere, MoSi2 holds a distinct advantage.

Aging and Maintenance

SiC elements "age" over their lifespan, meaning their electrical resistance gradually increases with use. This requires a power supply with a variable voltage output to maintain consistent power delivery over time.

MoSi2 elements have a relatively stable resistance throughout their life. A significant advantage is that individual failed MoSi2 elements can often be replaced one by one, whereas SiC elements are typically replaced as a complete set.

Making the Right Choice for Your Process

Your specific operational goal is the ultimate guide. Consider the primary demand of your application to make a definitive choice.

- If your primary focus is reaching temperatures above 1600°C in an oxidizing atmosphere: MoSi2 is your necessary and ideal choice.

- If your primary focus is process versatility with varied atmospheres or frequent, rapid thermal cycling: SiC provides superior robustness and operational flexibility.

- If your primary focus is maximum durability and resistance to mechanical or thermal shock below 1600°C: SiC is the more forgiving and physically stronger option.

- If your primary focus is minimizing maintenance downtime for single-element failures: MoSi2's ability to be individually replaced can be a significant long-term benefit.

By aligning the unique properties of each material with your specific operational demands, you ensure optimal furnace performance, reliability, and cost-effectiveness.

Summary Table:

| Factor | MoSi2 | SiC |

|---|---|---|

| Max Operating Temperature | Up to 1800°C | Up to 1600°C |

| Atmosphere Compatibility | Requires oxidizing (e.g., air) | Versatile: oxidizing, neutral, reducing |

| Mechanical Strength | Brittle, prone to thermal shock | High strength, resistant to thermal shock |

| Power Density | Higher watt loading, faster heating | Lower watt loading |

| Maintenance | Stable resistance, individual element replacement | Aging increases resistance, full set replacement |

Struggling to select the right heating element for your high-temperature processes? At KINTEK, we specialize in advanced furnace solutions tailored to your unique needs. Leveraging exceptional R&D and in-house manufacturing, we offer a diverse product line including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your experimental requirements, enhancing performance, reliability, and cost-effectiveness. Don't let element choice compromise your results—contact us today to discuss how we can optimize your furnace setup!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What makes SIC heating elements superior for high-temperature applications? Unlock Efficiency and Durability

- What makes silicon carbide heating elements resistant to chemical corrosion? Discover the Protective Oxide Layer

- Why are silicon carbide heating elements essential in high-temperature industries? Unlock Reliable, Extreme Heat Solutions

- What are the properties and capabilities of Silicon Carbide (SiC) as a heating element? Unlock Extreme Heat and Durability

- Why is silicon carbide resistant to chemical reactions in industrial furnaces? Unlock Durable High-Temp Solutions