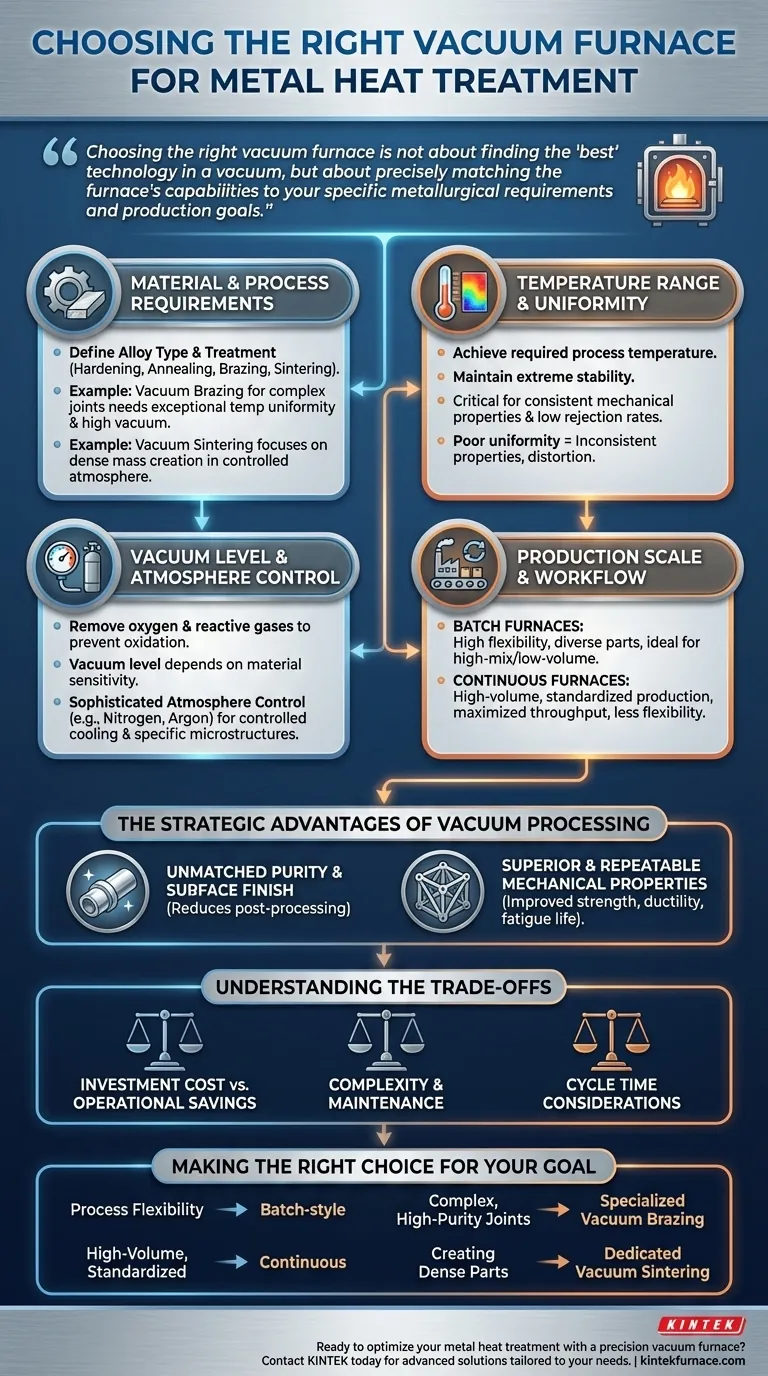

When choosing a vacuum furnace for metal heat treatment, your decision must be guided by four primary factors: the specific material and process you will use, the required temperature range and uniformity, the necessary vacuum level and atmosphere control, and your overall production volume and workflow. These elements work together to determine the quality of your final product, your operational efficiency, and your return on investment.

Choosing the right vacuum furnace is not about finding the "best" technology in a vacuum, but about precisely matching the furnace's capabilities to your specific metallurgical requirements and production goals. The wrong choice can lead to inconsistent quality, operational bottlenecks, and unnecessary costs.

Deconstructing the Core Decision Factors

The selection process is a systematic evaluation of how your needs align with the furnace's technical specifications. The most critical error is to focus on one factor, like temperature, while neglecting others that are equally vital for the desired outcome.

Material & Process Requirements

The first question is always what you are trying to achieve. The metal alloy and the intended heat treatment process—such as hardening, annealing, tempering, brazing, or sintering—dictate all other requirements.

For example, vacuum brazing for joining complex assemblies requires exceptional temperature uniformity and a high vacuum to ensure the purity of the joint. In contrast, vacuum sintering for powder metallurgy focuses on creating a dense, solid mass in a controlled atmosphere.

Temperature Range & Uniformity

You must select a furnace that can not only reach the required process temperature but also maintain it with extreme stability. Temperature uniformity across the entire hot zone is critical for ensuring every part in a batch receives the exact same treatment.

Poor uniformity can lead to inconsistent mechanical properties, distortion, and a high rejection rate, particularly for sensitive aerospace or medical components.

Vacuum Level & Atmosphere Control

The "vacuum" in a vacuum furnace is not a single state. The required vacuum level—from a rough vacuum to a high vacuum—depends on the material's sensitivity to oxidation and contamination. The primary purpose of the vacuum is to remove oxygen and other reactive gases.

Furthermore, modern furnaces offer sophisticated atmosphere control, allowing for the backfilling of inert gases like nitrogen or argon. This is essential for controlled cooling (quenching) to achieve specific microstructures and hardness levels.

Production Scale: Batch vs. Continuous

Your production volume dictates the furnace's fundamental design.

- Batch Furnaces: These are the most common type, offering high flexibility for processing different part types, sizes, and processes in separate cycles. They are ideal for high-mix, low-volume production or job shops.

- Continuous Furnaces: These systems are designed for high-volume, standardized production. Parts move uninterrupted through heating and cooling zones, maximizing throughput and energy efficiency but offering less flexibility.

Cooling System & Quench Capabilities

The heat treatment cycle doesn't end when the peak temperature is reached. The cooling rate is just as critical for determining the final properties of the metal.

The furnace's quenching system, which often uses high-pressure inert gas, must be capable of cooling the parts at a controlled rate to achieve the desired hardness and minimize thermal stress and distortion.

The Strategic Advantages of Vacuum Processing

Understanding why vacuum furnaces are chosen helps clarify the importance of the selection factors. The value lies in the pristine processing environment they create.

Unmatched Purity and Surface Finish

By removing oxygen, vacuum furnaces prevent oxidation, decarburization, and discoloration. This results in bright, clean parts that often require no secondary cleaning operations, reducing labor and material costs.

This process also purifies the metal's surface through degassing, removing trapped impurities to create a higher-quality final product.

Superior and Repeatable Mechanical Properties

The highly controlled heating and cooling cycles enable the precise engineering of a material's microstructure. This leads to improved strength, ductility, and fatigue life.

Because the process is automated and computer-controlled, it is highly repeatable. This ensures that the first part and the thousandth part have identical properties, which is a non-negotiable requirement in critical industries like aerospace and automotive manufacturing.

Understanding the Trade-offs

While powerful, vacuum furnaces are a significant investment with specific operational considerations. An objective evaluation must include the potential challenges.

Investment Cost vs. Operational Savings

Vacuum furnaces carry a higher initial capital cost than many traditional atmosphere furnaces. This investment must be weighed against long-term operational savings from higher part quality, elimination of post-processing, reduced scrap rates, and superior energy efficiency.

Complexity and Maintenance

These are sophisticated systems integrating high-vacuum pumps, advanced controls, and robust cooling systems. They require skilled operators and a diligent preventive maintenance program to ensure reliable, long-term performance.

Cycle Time Considerations

For a batch furnace, the total cycle time includes pumping down to the required vacuum level, heating, soaking, and cooling. While the heating and cooling can be rapid, the overall pump-down time can make the total cycle longer than some atmospheric processes. This is a key reason why high-volume production gravitates toward continuous furnaces.

Making the Right Choice for Your Goal

Your final decision should be a direct reflection of your primary operational objective.

- If your primary focus is process flexibility and varied parts: A batch-style furnace offers the versatility to handle diverse jobs and treatment cycles efficiently.

- If your primary focus is high-volume, standardized production: A continuous vacuum furnace will deliver the best throughput and lowest cost-per-part at scale.

- If your primary focus is joining complex, high-purity assemblies: Prioritize a furnace designed specifically for vacuum brazing with exceptional temperature uniformity and high-vacuum capabilities.

- If your primary focus is creating dense parts from metal powders: A dedicated vacuum sintering furnace with precise atmosphere control is essential for achieving the required final density and material properties.

By aligning these technical factors with your production goals, you can select a furnace that becomes a strategic asset rather than just a piece of equipment.

Summary Table:

| Factor | Key Considerations |

|---|---|

| Material & Process | Alloy type, heat treatment process (e.g., hardening, brazing, sintering) |

| Temperature Range & Uniformity | Required max temperature, stability, and uniformity across hot zone |

| Vacuum Level & Atmosphere Control | Vacuum level (rough to high), inert gas backfilling for quenching |

| Production Scale | Batch vs. continuous furnaces based on volume and flexibility |

| Cooling System | Quenching capabilities with controlled cooling rates |

Ready to optimize your metal heat treatment with a precision vacuum furnace? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all supported by strong deep customization capabilities to meet your unique experimental requirements. Whether you're in aerospace, automotive, or other industries, we ensure superior purity, repeatable results, and enhanced efficiency. Contact us today to discuss how our furnaces can elevate your production and deliver unmatched value!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What is the process of vacuum heat treatment? Achieve Superior Metallurgical Properties

- How does a vacuum furnace prevent heat transfer and contamination? Achieve Ultimate Material Purity

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- What is a vacuum furnace used for? Achieve Purity and Precision in High-Temp Processing

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today