Ultimately, the specific parameters of a box-type atmosphere furnace are dictated by its intended application. The temperature range, chamber size, and type of atmosphere control are not arbitrary; they are direct responses to the specific material being processed and the desired outcome of that process, whether for research or industrial production.

The core challenge is not finding the "best" furnace, but rather defining your process needs with precision. Once your material, desired outcome, and operational scale are clear, the required furnace specifications naturally follow.

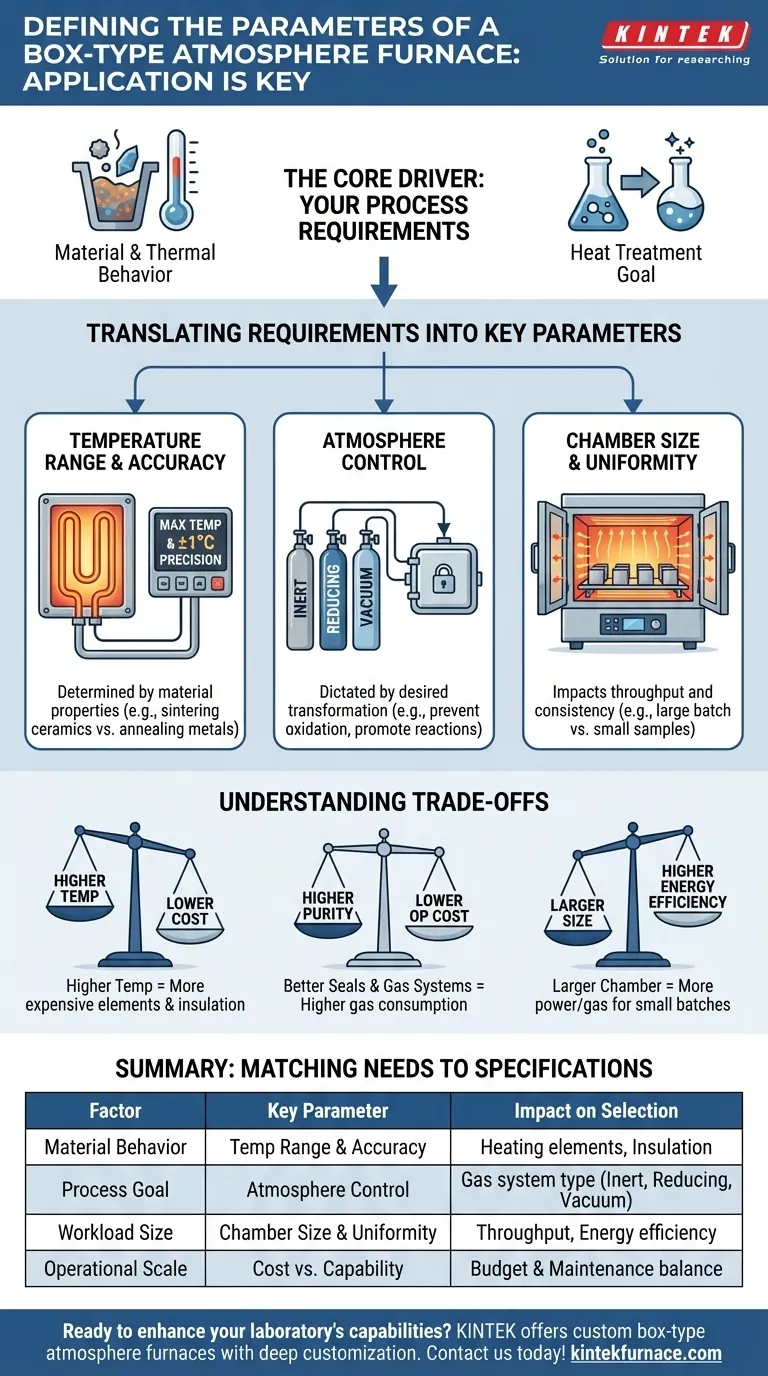

The Core Driver: Your Process Requirements

Before evaluating any furnace model, you must first define the problem you are trying to solve. The furnace is a tool, and its specifications must match the job at hand.

What is your material and its thermal behavior?

The primary factor is the material you will be heating. Its chemical and physical properties determine the most critical furnace parameters.

For example, sintering advanced ceramics requires extremely high temperatures, while annealing certain metals might require more moderate heat but very strict atmospheric control.

What is the goal of the heat treatment?

The desired transformation of your material dictates the environment it needs. Are you trying to harden a metal, bind powdered materials together, or remove impurities?

This goal directly translates into the need for an inert, reducing, or vacuum atmosphere to prevent oxidation, promote specific chemical reactions, or protect the material's integrity.

Translating Requirements into Key Parameters

Once you have defined your process, you can map those needs directly to the furnace's technical specifications.

Temperature Range & Accuracy

The maximum temperature is the most fundamental parameter, driven entirely by your process. Furnaces can range from 1000°C for general applications to over 2000°C for specialized materials.

Temperature control accuracy, often within ±1°C to ±5°C, is critical for processes where slight deviations can ruin the final product. This precision is managed by the temperature control system and the quality of the heating elements.

Atmosphere Control

This is the defining feature of an atmosphere furnace. The choice of gas system is based on whether you need to protect your material or actively influence it.

- Inert Gas (Nitrogen, Argon): Used to create a protective, non-reactive environment to prevent oxidation and contamination. This is the most common requirement.

- Reducing Gas (Hydrogen): Used to actively remove oxygen from the material's surface, often required in specific metallurgical or chemical processes.

- Vacuum: Used to remove all atmospheric gases, which is essential for highly sensitive materials or to promote outgassing.

Chamber Size and Uniformity

The internal chamber size must be large enough to accommodate your workpiece or batch size. This decision directly impacts throughput and operational efficiency.

However, size is not the only consideration. Temperature uniformity across the entire chamber is crucial for ensuring that every part of your workload receives the exact same heat treatment, guaranteeing consistent results.

Core Structural Components

These primary requirements then inform the selection of the furnace's physical components.

The required temperature range dictates the choice of heating elements (e.g., resistance wire) and insulation materials (e.g., ceramic fiber) needed to safely and efficiently reach and maintain that heat. The need for a specific atmosphere dictates the quality of the chamber seals and the sophistication of the gas supply system.

Understanding the Trade-offs

Selecting a furnace involves balancing capabilities with practical constraints. There is no single solution that is perfect for every application.

Higher Temperature vs. Cost

Achieving higher temperatures (above 1700°C) requires more advanced, expensive heating elements and insulation materials. This significantly increases both the initial purchase price and long-term maintenance costs.

Atmosphere Purity vs. Operational Cost

Maintaining a high-purity atmosphere with minimal leakage demands superior chamber sealing and more complex gas delivery systems. This results in higher upfront costs and increased consumption of expensive gases like argon or hydrogen.

Chamber Size vs. Energy Efficiency

A larger chamber provides higher throughput but is significantly less energy-efficient for processing small, individual samples. It consumes more power and gas to heat and purge the larger volume, making it wasteful for small-batch work.

How to Specify Your Ideal Furnace

Use your primary process goal to prioritize the most important furnace parameters.

- If your primary focus is high-temperature materials research: Prioritize the maximum temperature range and precise, programmable temperature control to explore material limits.

- If your primary focus is preventing oxidation in sensitive metals: Prioritize the sealing performance of the chamber and the quality of the inert gas control system.

- If your primary focus is consistent, high-volume production: Prioritize chamber size, temperature uniformity, and robust safety and automation features for reliable, repeatable operation.

By clearly defining your application first, you can select a furnace that is not just capable, but perfectly suited to your specific technical and operational needs.

Summary Table:

| Factor | Key Parameter | Impact on Furnace Selection |

|---|---|---|

| Material & Thermal Behavior | Temperature Range & Accuracy | Determines heating elements and insulation for specific processes |

| Process Goal | Atmosphere Control | Influences gas system (inert, reducing, vacuum) for oxidation prevention or reactions |

| Workload Size | Chamber Size & Uniformity | Affects throughput and energy efficiency for consistent heat treatment |

| Operational Scale | Cost vs. Capability | Balances temperature, purity, and size with budget and maintenance needs |

Ready to enhance your laboratory's capabilities with a custom box-type atmosphere furnace? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures your unique experimental requirements are met precisely, boosting efficiency and reliability. Contact us today to discuss how we can tailor a furnace to your specific needs!

Visual Guide

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- How does an inert atmosphere prevent oxidation? Shield Materials from Oxygen Damage

- How does nitrogen atmosphere heat treatment improve surface strengthening? Enhance Durability and Performance

- How does a chemically inert atmosphere function in a furnace? Prevent Oxidation and Ensure Material Purity

- What are the benefits of inert atmosphere heat treating? Prevent Oxidation and Preserve Material Integrity

- How does the inert atmosphere heat treating process work? Prevent Oxidation for Superior Material Quality