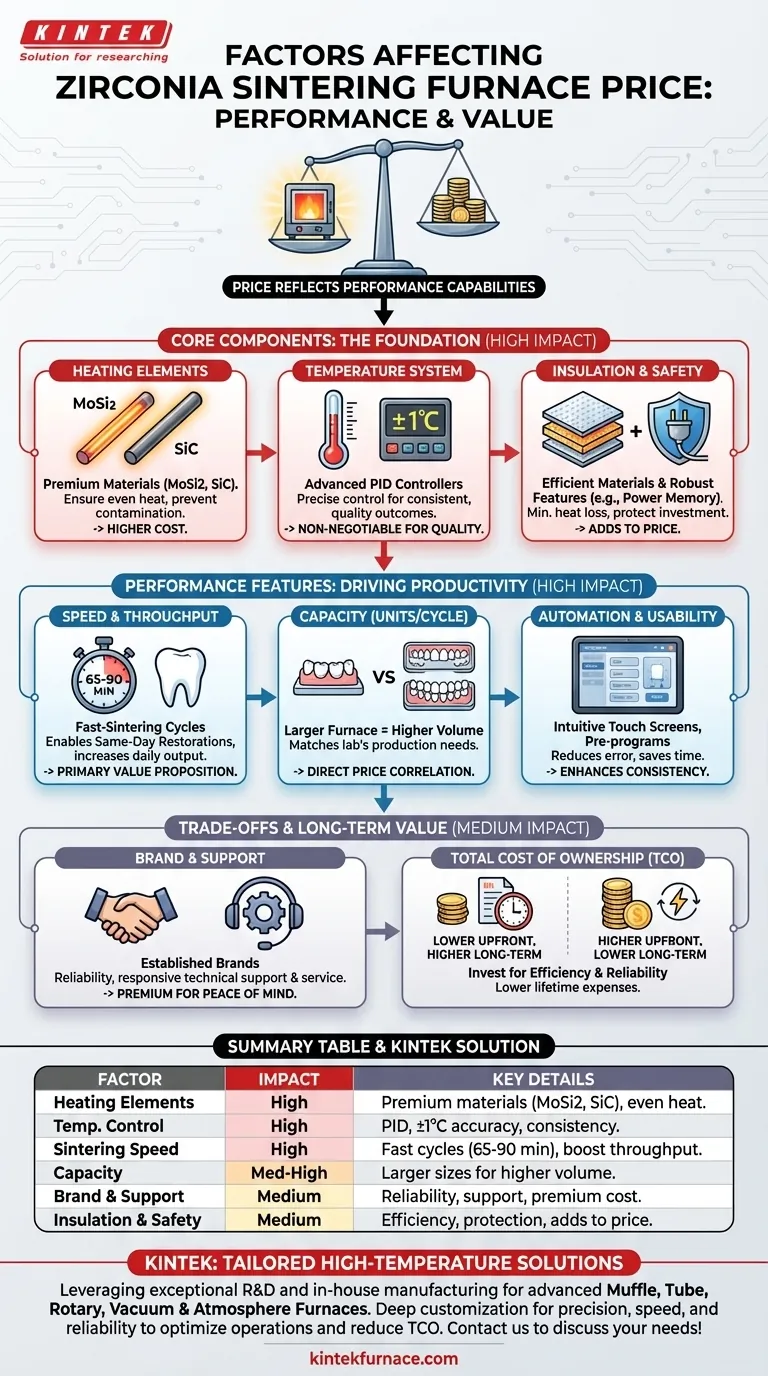

Ultimately, the price of a zirconia sintering furnace is a direct reflection of its performance capabilities. The cost is determined by the quality of its core components, its operational speed and capacity, and the sophistication of its control systems. Prices can range from several thousand dollars for basic models to tens of thousands for high-performance units designed for maximum laboratory throughput.

The sticker price of a furnace is only part of the story. The real calculation involves weighing the upfront investment against the long-term return in productivity, reliability, and the quality of the final restorations. A higher-priced furnace often pays for itself through increased speed and reduced operational costs.

Deconstructing the Cost: Core Components

The internal hardware of a furnace is the foundation of its performance and a primary driver of its price. Cutting-edge components deliver better results and have a longer operational life, but they come at a premium.

The Heart of the Furnace: Heating Elements

The type and quality of heating elements are critical. High-purity molybdenum disilicide (MoSi2) or silicon carbide (SiC) rods are the industry standard for high-performance furnaces.

These premium elements ensure even heat distribution and prevent contamination of the zirconia, which is essential for achieving predictable esthetics and strength. Cheaper furnaces may use lower-grade elements that can wear out faster and compromise the final restoration.

Precision and Control: The Temperature System

Achieving the correct translucency and strength in zirconia requires exceptionally precise temperature management.

Top-tier furnaces use sophisticated PID (Proportional-Integral-Derivative) controllers and high-accuracy thermocouples. This allows for temperature control with an accuracy of ±1℃, ensuring that sintering profiles are followed exactly. This precision is a non-negotiable feature for consistent, high-quality clinical outcomes and carries a corresponding cost.

Efficiency and Build: Insulation and Safety

The quality of the furnace's insulation directly impacts its energy efficiency and temperature stability.

Advanced, environmentally-friendly thermal materials minimize heat loss, reducing electricity consumption over the furnace's lifetime. Furthermore, robust safety features like over-temperature protection and power interruption memory (to resume a cycle after an outage) contribute to a higher price but are invaluable for protecting your investment and preventing lost work.

Performance Features That Drive Price and Productivity

Beyond the core components, specific features determine how a furnace integrates into a lab's workflow. These features are often the biggest differentiators in price between entry-level and premium models.

Speed: The Value of Fast Sintering

The ability to complete a sintering cycle quickly is perhaps the most significant value proposition of a modern furnace. While standard cycles can take many hours, high-end models offer fast-sintering programs that can be completed in as little as 65-90 minutes.

This speed enables a lab to offer same-day restorations and dramatically increase daily throughput, directly impacting profitability. This performance capability is a primary justification for a higher price point.

Capacity: Units Per Cycle

Furnace size directly correlates with price. A small furnace designed for a few single units will be significantly cheaper than a large-capacity model capable of sintering multiple full-arch bridges simultaneously.

The choice here is a simple calculation of your lab's current and projected case volume. A larger capacity supports a higher-volume production environment.

Automation and Usability

Modern furnaces emphasize ease of use to reduce operator error and training time. Features like a large color touch screen, pre-programmed settings for various zirconia brands, and intuitive interfaces add to the cost.

While a simpler interface may function adequately, a highly automated and user-friendly system saves valuable technician time and ensures greater consistency in the production process.

Understanding the Trade-offs

A furnace is a long-term investment, and the initial purchase price is only one factor in its overall cost.

Brand Reputation and Support

Established brands often command higher prices. This premium is not just for the name; it reflects a track record of reliability, proven performance, and, most importantly, access to responsive technical support and service. When a critical piece of equipment fails, quality support is invaluable.

Upfront Cost vs. Total Cost of Ownership

A low-cost furnace may seem attractive, but it can lead to higher long-term expenses. Cheaper models may consume more energy, require more frequent replacement of heating elements, or have a higher failure rate leading to costly downtime.

Conversely, a more expensive, efficient, and reliable furnace can result in a lower total cost of ownership over its lifespan.

Supplier and Regional Factors

Finally, the price you pay will be influenced by the specific supplier or distributor and their associated markup. Regional factors, including shipping costs, import duties, and local market competition, will also affect the final price.

Selecting the Right Furnace for Your Lab's Goals

Choosing a furnace requires aligning its capabilities with your lab's specific business objectives.

- If your primary focus is maximizing throughput and offering same-day service: Prioritize furnaces with proven fast-sintering cycles and a capacity that matches your case volume.

- If your primary focus is a boutique lab centered on high-end esthetics: Invest in a furnace with exceptional temperature precision and high-purity heating elements to guarantee consistent, high-quality results.

- If your primary focus is minimizing initial investment for a new or small lab: A basic, reliable model with a smaller capacity and standard cycle times is a viable starting point, but be prepared for lower productivity.

Ultimately, view this purchase not as an expense, but as a strategic investment in your laboratory's production capacity and quality standards.

Summary Table:

| Factor | Impact on Price | Key Details |

|---|---|---|

| Heating Elements | High | Premium materials (MoSi2, SiC) ensure even heat, prevent contamination, and increase cost. |

| Temperature Control | High | PID controllers with ±1℃ accuracy for consistent results and higher pricing. |

| Sintering Speed | High | Fast-sintering programs (65-90 min) boost throughput but add to expense. |

| Capacity | Medium to High | Larger sizes for multiple units increase price based on lab volume needs. |

| Brand and Support | Medium | Established brands offer reliability and support, justifying premium costs. |

| Insulation and Safety | Medium | Advanced materials improve efficiency and safety, affecting overall price. |

Ready to enhance your lab's productivity with a tailored zirconia sintering furnace? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure we meet your unique experimental needs, delivering precision, speed, and reliability. Contact us today to discuss how our high-temperature furnace solutions can optimize your operations and reduce total cost of ownership!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- Why is accurate temperature control important in dental furnaces? Ensure Perfect Restorations Every Time

- What are the benefits of using dental sintering and porcelain furnaces? Enhance Strength, Aesthetics, and Efficiency

- What are some key features of dental sintering and porcelain furnaces? Optimize Your Dental Lab's Workflow

- What are the primary functions of ceramic dental furnaces? Achieve Precision and Durability in Dental Restorations

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision