From an environmental standpoint, the primary benefit of electric kilns is their complete lack of direct emissions during operation. Unlike gas or wood-fired kilns that burn fuel and release combustion byproducts, an electric kiln produces no carbon monoxide, soot, or other pollutants into your immediate workspace or local atmosphere. This makes it an inherently cleaner technology at the point of use.

While an electric kiln eliminates on-site pollution, its true environmental footprint is determined by the source of its electricity. The key benefit is shifting the point of impact from your studio to the power grid, a trade-off that can be highly advantageous depending on how your local energy is generated.

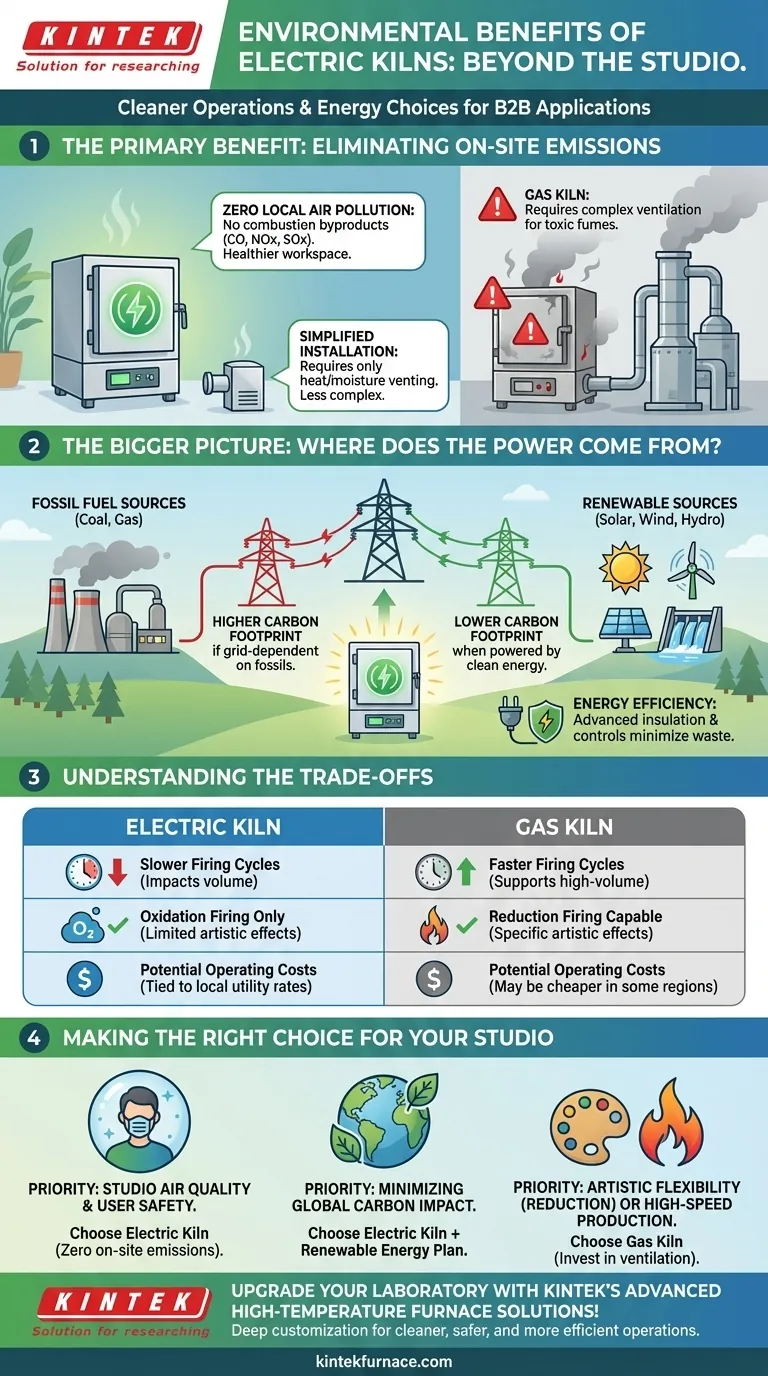

The Primary Benefit: Eliminating On-Site Emissions

The most immediate and tangible environmental advantage of an electric kiln is the improvement in local air quality. This has direct implications for both the user and the surrounding environment.

Zero Local Air Pollution

Because no fuel is burned at the kiln, there are no exhaust fumes. This means zero release of harmful gases like carbon monoxide (CO), nitrogen oxides (NOx), or sulfur oxides (SOx) from the firing process itself.

This creates a healthier working environment, removing the significant health risks associated with inhaling combustion byproducts.

Simplified Installation and Venting

Gas kilns require robust and complex ventilation systems to safely expel toxic fumes. Electric kilns, by contrast, only need venting to manage heat and moisture released from the clay, which simplifies installation and reduces infrastructure needs.

The Bigger Picture: Where Does the Power Come From?

An electric kiln does not eliminate emissions; it displaces them. Understanding this distinction is crucial for assessing its overall environmental impact.

The Role of the Energy Grid

The environmental cost of running an electric kiln is directly tied to your electricity provider. If your power comes from a grid dominated by coal or natural gas, then running your kiln still contributes to greenhouse gas emissions, albeit at the power plant instead of your studio.

Impact of Renewable vs. Fossil Fuel Sources

The true environmental strength of an electric kiln is realized when it is paired with clean energy. A kiln powered by solar, wind, hydro, or nuclear energy has a dramatically lower carbon footprint than one powered by fossil fuels.

Many energy providers now offer "green" or renewable energy plans, allowing you to source cleaner power even if you don't have your own solar panels.

Understanding Energy Efficiency

Modern electric kilns are engineered for high efficiency. They use advanced insulation and digital controllers to retain heat effectively, minimizing the amount of electricity wasted during a firing cycle. This efficiency is an environmental benefit regardless of the power source, as it reduces overall energy demand.

Understanding the Trade-offs

Choosing an electric kiln for its environmental benefits involves accepting certain operational and artistic trade-offs compared to fuel-burning alternatives.

Slower Firing Cycles

Electric kilns generally heat up and cool down more slowly than their gas counterparts. This can impact production schedules for high-volume studios.

Limited Atmospheric Control

Electric kilns excel at oxidation firing, creating a clean, oxygen-rich environment. However, they cannot easily perform reduction firing, a technique used with gas kilns that starves the atmosphere of oxygen to achieve specific, often dramatic, glaze effects. This is a significant artistic limitation for some ceramicists.

Potential Operating Costs

The cost-effectiveness of an electric kiln depends entirely on local utility rates. In regions with high electricity prices and cheap natural gas, a gas kiln may be less expensive to operate.

Making the Right Choice for Your Studio

The best kiln for you depends on a careful balance of your environmental concerns, artistic needs, and practical constraints.

- If your primary focus is studio air quality and user safety: An electric kiln is the undisputed winner, as it produces no harmful on-site emissions.

- If your primary focus is minimizing global carbon impact: Choose an electric kiln and actively power it with a renewable energy source or a green energy plan from your utility provider.

- If your primary focus is artistic flexibility (reduction effects) or high-speed production: A gas kiln may be necessary, but you must invest in proper ventilation and acknowledge its direct environmental footprint.

By understanding that the impact of an electric kiln is tied to its power source, you can make an informed decision that aligns with both your artistic goals and your environmental values.

Summary Table:

| Benefit | Description |

|---|---|

| Zero On-Site Emissions | No release of CO, NOx, or SOx during operation, enhancing local air quality. |

| Simplified Ventilation | Only requires heat and moisture venting, reducing installation complexity. |

| Energy Efficiency | Advanced insulation and digital controls minimize electricity waste. |

| Renewable Energy Compatibility | Can be powered by solar, wind, or other clean sources for lower carbon footprint. |

Upgrade your laboratory with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide electric kilns and other products like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise solutions for your unique experimental needs, helping you achieve cleaner, safer, and more efficient operations. Contact us today to discuss how we can support your environmental and performance goals!

Visual Guide

Related Products

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

People Also Ask

- How does the raw meal move inside the rotary kiln? Master Controlled Flow for Efficient Processing

- What are the main components in the construction of a rotary kiln? A Guide to the Core Systems

- What is an electric heating rotary kiln and what industries use it? Discover Precision Heating for High-Purity Materials

- How does automated control in electric rotary kilns benefit industrial processes? Achieve Unmatched Precision & Efficiency

- How is bed depth controlled in a rotary kiln and why is it important? Optimize Heat Transfer and Efficiency