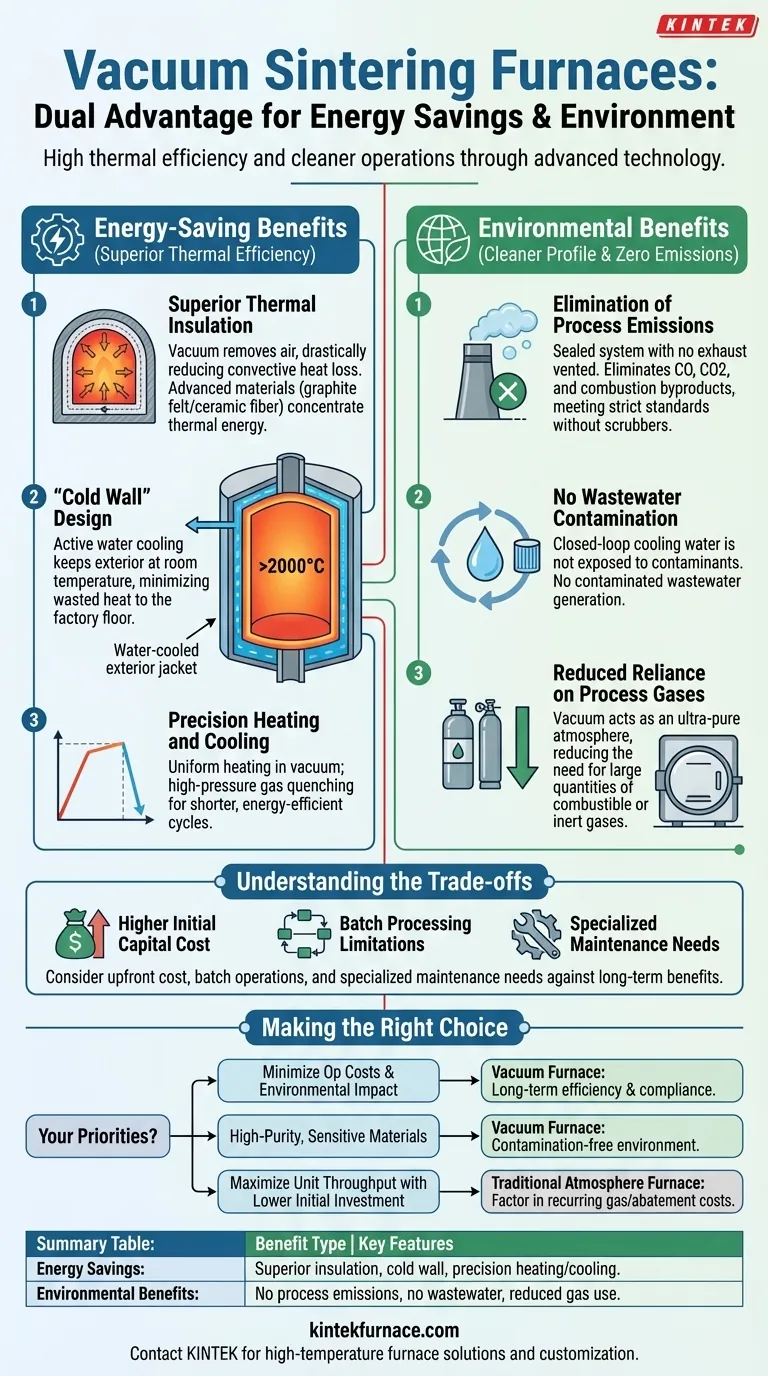

At their core, vacuum sintering furnaces provide a dual advantage of significant energy savings through superior thermal efficiency and a cleaner environmental profile by virtually eliminating process emissions. The sealed vacuum environment is the key technology that enables both benefits, making it an indispensable tool for modern, high-performance manufacturing.

The fundamental benefit of a vacuum furnace is its sealed, controlled environment. This design not only minimizes energy waste by preventing heat loss but also inherently contains all byproducts, negating the need for the complex and costly exhaust or wastewater treatment systems required by traditional atmosphere furnaces.

How Vacuum Furnaces Drive Energy Efficiency

The energy savings from a vacuum furnace are not incidental; they are a direct result of its fundamental design principles. This efficiency lowers operational costs and reduces the overall carbon footprint of the manufacturing process.

Superior Thermal Insulation

A vacuum is one of the most effective insulators known. By removing air and other gases that would otherwise transfer heat via convection, the furnace chamber dramatically reduces passive heat loss to the surrounding environment.

This is further enhanced by advanced insulation materials, such as graphite felt or ceramic fiber, that line the furnace's interior, keeping thermal energy concentrated in the hot zone where it is needed.

The 'Cold Wall' Design

Most modern vacuum furnaces employ a "cold wall" design. The outer vessel is jacketed and actively cooled with water.

This design ensures that the vessel's exterior remains at or near room temperature, even when the interior hot zone reaches temperatures exceeding 2000°C. This means energy is kept inside the furnace to do useful work, not wasted heating the factory floor.

Precision Heating and Cooling

Vacuum environments allow for highly responsive and uniform heating, ensuring energy is applied precisely and not wasted on overcoming atmospheric variables.

Furthermore, features like high-pressure gas quenching allow for controlled, accelerated cooling cycles. Shortening the overall cycle time means the furnace consumes energy for a shorter duration, directly contributing to efficiency.

The Environmental Impact: A Closed-Loop System

A vacuum furnace is inherently a closed system, which provides significant and straightforward environmental advantages over furnaces that vent to the atmosphere.

Elimination of Process Emissions

Because the system is sealed and operates under a vacuum, there are no exhaust gases vented to the atmosphere. This completely eliminates the release of carbon monoxide, carbon dioxide, or other byproducts of combustion or process reactions common in traditional furnaces.

This design inherently meets strict environmental standards without requiring secondary scrubbers, afterburners, or other costly emission control equipment.

No Wastewater Contamination

Unlike atmosphere furnaces that may use wet scrubbing systems to clean their exhaust, vacuum furnaces produce no contaminated wastewater. The closed-loop water used for the cold wall design is not exposed to process contaminants and can be recirculated efficiently.

Reduced Reliance on Process Gases

Many sintering processes require a specific atmosphere to prevent oxidation. In a vacuum furnace, the vacuum itself serves as the perfect, ultra-pure "atmosphere," eliminating the need to purchase, store, and handle large quantities of combustible or inert process gases like hydrogen or argon. This simplifies operations and improves workplace safety.

Understanding the Trade-offs

While highly beneficial, vacuum furnaces are not the universal solution for every application. Understanding their limitations is key to making an informed decision.

Higher Initial Capital Cost

Vacuum furnaces are complex machines incorporating sophisticated vacuum pumps, seals, and control systems. This typically results in a higher upfront investment compared to simpler, continuous-belt atmosphere furnaces.

Batch Processing Limitations

The vast majority of vacuum furnaces operate in batches, where parts are loaded, the chamber is sealed, a cycle is run, and parts are unloaded. This may be less efficient for certain very high-volume, continuous-flow production lines.

Specialized Maintenance Needs

The high-performance components, particularly the vacuum pumping system and seals, require a higher level of maintenance expertise than conventional furnace systems.

Making the Right Choice for Your Goal

Your decision should be guided by your specific priorities, balancing upfront cost against long-term operational performance and compliance.

- If your primary focus is minimizing operational costs and environmental impact: A vacuum furnace is a superior long-term choice due to its energy efficiency and lack of emissions, reducing ongoing utility and compliance expenses.

- If your primary focus is producing high-purity, oxidation-sensitive materials: The contamination-free environment of a vacuum furnace is non-negotiable for achieving the required material properties and minimizing scrap.

- If your primary focus is maximizing unit throughput with a lower initial investment: A traditional continuous atmosphere furnace might be suitable, but you must factor in the recurring costs of process gases and environmental abatement.

Ultimately, adopting a vacuum sintering furnace is an investment in precision, operational efficiency, and long-term environmental responsibility.

Summary Table:

| Benefit Type | Key Features |

|---|---|

| Energy Savings | Superior thermal insulation, cold wall design, precision heating/cooling |

| Environmental Benefits | No process emissions, no wastewater, reduced process gas use |

Ready to enhance your lab's efficiency and sustainability? KINTEK specializes in high-temperature furnace solutions, including Vacuum & Atmosphere Furnaces, with deep customization to meet your unique needs. Contact us today to learn how our advanced technologies can save energy and reduce environmental impact for your operations!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What is the role of vacuum pumps in a vacuum heat treatment furnace? Unlock Superior Metallurgy with Controlled Environments

- Why is a high vacuum essential for Ti-6Al-4V sintering? Protect Your Alloys from Embrittlement

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- What tasks does a high-temperature vacuum sintering furnace perform for PEM magnets? Achieve Peak Density

- What is the purpose of setting a mid-temperature dwell stage? Eliminate Defects in Vacuum Sintering