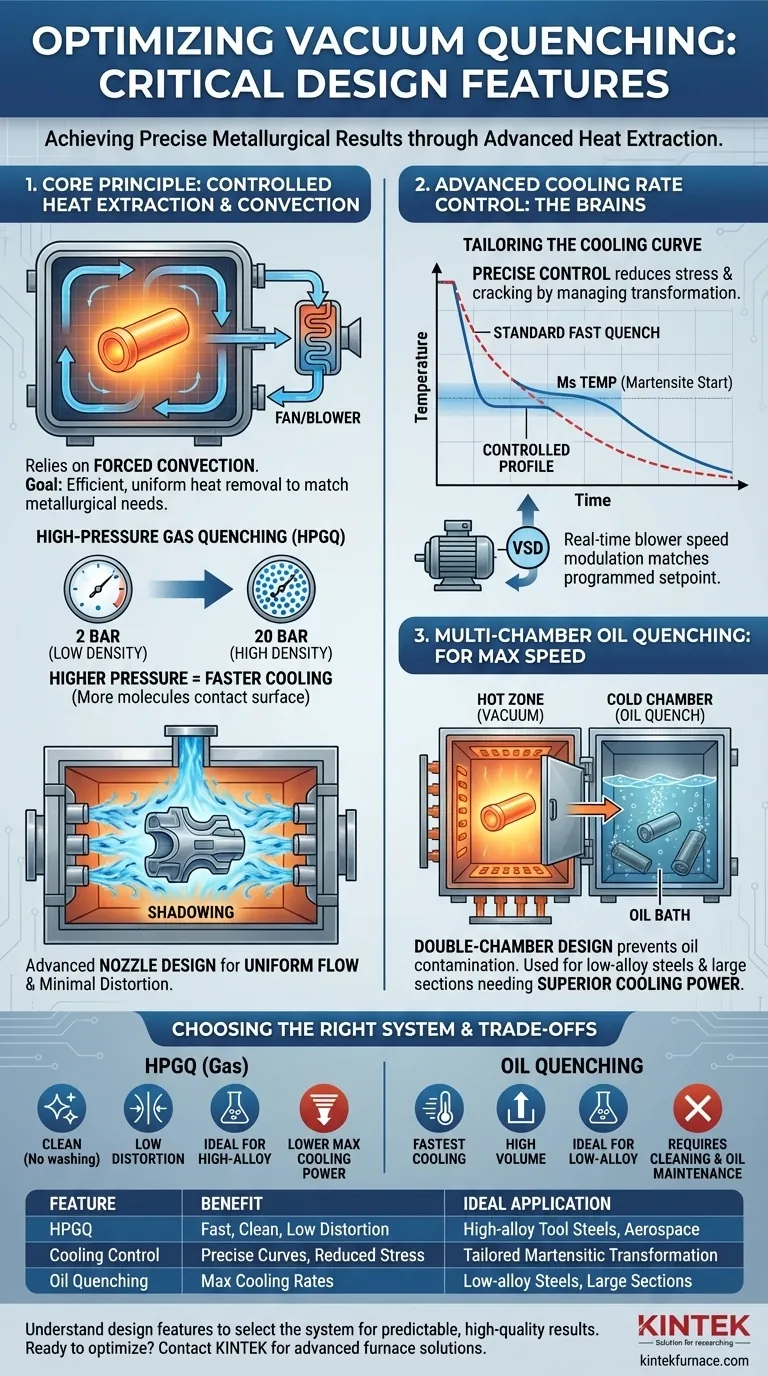

At its core, optimizing a vacuum quenching process comes down to three critical design elements: the use of high-pressure gas quenching (HPGQ), sophisticated cooling rate control systems, and multi-chamber configurations for oil quenching when required. These features work together to precisely manage heat extraction, which is the fundamental goal of any quenching operation.

The most effective vacuum furnace is not simply the one that cools the fastest. Instead, it is the one that provides the most precise and repeatable control over the cooling rate, allowing you to match the process to the specific metallurgical needs of the material.

The Core Principle: Controlled Heat Extraction

The primary purpose of quenching is to cool a heated component at a specific rate to achieve a desired metallurgical microstructure, such as martensite, which imparts hardness and strength.

Vacuum furnaces provide an exceptionally clean, inert environment for heating. The optimization challenge lies entirely in how efficiently and uniformly heat is removed during the cooling cycle.

The Role of Convection

Unlike open-air quenching where heat is removed by multiple methods, vacuum quenching relies almost exclusively on forced convection.

A powerful fan or blower circulates a quenching gas (typically nitrogen or helium) through the hot zone. The gas absorbs heat from the parts and transfers it to a heat exchanger, which cools the gas before it is recirculated.

High-Pressure Gas Quenching (HPGQ): The Modern Standard

For most modern tool steels and high-performance alloys, HPGQ is the preferred method. Its optimization hinges on pressure, flow, and gas type.

Why High Pressure Matters

The ability of a gas to absorb heat is directly related to its density. Increasing the gas pressure from 2 bar to 20 bar dramatically increases the number of gas molecules available to contact the part's surface.

This results in a significantly higher heat transfer coefficient, allowing for much faster cooling rates that are necessary to harden many types of steel. A 20-bar system represents the high end of modern HPGQ capability.

The Importance of Nozzle Design

Simply having high pressure is not enough. The gas must be delivered uniformly over the entire surface of the workload.

Advanced furnaces use strategically placed nozzles designed to create a turbulent, high-velocity flow that envelops the parts. This prevents "shadowing," where some areas cool slower than others, which is a primary cause of distortion and non-uniform hardness.

Advanced Cooling Rate Control: The Brains of the Operation

The most significant leap in vacuum quenching technology is the ability to precisely control the cooling curve. The goal is not always to quench as fast as possible.

Tailoring the Martensitic Transformation

For many high-alloy tool steels, cooling too quickly through the martensitic transformation start (Ms) temperature can induce extreme internal stresses, leading to distortion or even cracking.

Advanced control systems allow operators to program a specific cooling profile. This often involves rapid cooling to just above the Ms temperature, followed by a slower, controlled cool through the transformation range to mitigate stress.

How It's Achieved: Convection Control

This level of control is achieved by using variable speed drives (VSDs) on the main circulation blower.

By modulating the blower's speed, the furnace's control system can increase or decrease the volume and velocity of the gas flow in real-time, precisely matching the actual cooling rate to the programmed setpoint.

Double Chambers for Oil Quenching

Some materials, particularly low-alloy steels or parts with very large cross-sections, require cooling rates that even 20-bar gas cannot achieve. For these applications, oil quenching is necessary.

When Gas Isn't Fast Enough

Oil has a vastly superior heat transfer capability compared to any gas. A vacuum oil quench furnace provides the benefits of clean vacuum heating with the aggressive cooling power of oil.

The Two-Chamber Design

To accomplish this safely and cleanly, these furnaces use a double-chamber design. The workload is heated in the high-temperature vacuum "hot zone."

Once at temperature, an internal door opens, and the workload is rapidly transferred to an adjacent, isolated "cold chamber" that is backfilled with inert gas and contains the quench oil. This design prevents oil vapors from contaminating the heating chamber and heating elements.

Understanding the Trade-offs

Choosing the right system involves balancing metallurgical needs against process complexity and cost.

Gas Quenching: Cleanliness vs. Cooling Power

HPGQ is exceptionally clean, eliminating the need for post-quench parts washing. It also generally produces less part distortion than liquid quenching. However, the initial capital cost for high-pressure systems is significant, and its cooling power is ultimately limited compared to oil.

Oil Quenching: Speed vs. Complexity

Vacuum oil quenching provides the fastest cooling rates possible, enabling the hardening of a wide range of steels. The trade-offs are the necessity of post-process cleaning, a higher risk of part distortion, and the maintenance and safety considerations associated with using quench oil.

Making the Right Choice for Your Goal

Your selection of a vacuum quenching system should be driven entirely by the materials you process and the properties you need to achieve.

- If your primary focus is high-alloy tool steels and aerospace components: Prioritize a high-pressure (10-20 bar) gas quench furnace with advanced cooling rate control for minimal distortion and precise metallurgical results.

- If your primary focus is low-alloy steels, large cross-sections, or high-volume production: A multi-chamber vacuum furnace with an integral oil quench is necessary to achieve the required hardness.

- If your primary focus is general-purpose heat treatment with maximum flexibility: A 6-10 bar HPGQ furnace offers a strong balance of performance for many common tool steels without the higher cost of a 20-bar system or the complexity of oil.

Ultimately, understanding these design features empowers you to select a system that delivers predictable, repeatable, and high-quality results for every part you treat.

Summary Table:

| Feature | Key Benefit | Ideal Application |

|---|---|---|

| High-Pressure Gas Quenching (HPGQ) | Fast, clean cooling with minimal distortion | High-alloy tool steels, aerospace components |

| Advanced Cooling Rate Control | Precise cooling curves to reduce stress and cracking | Materials requiring tailored martensitic transformation |

| Multi-Chamber for Oil Quenching | Maximum cooling rates for large sections | Low-alloy steels, high-volume production |

Ready to optimize your vacuum quenching process? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, with strong deep customization capabilities to meet unique experimental requirements. Contact us today to discuss how we can enhance your lab's efficiency and achieve precise metallurgical results!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- What is a vacuum furnace used for? Achieve Purity and Precision in High-Temp Processing

- What does a vacuum furnace do? Achieve Superior Material Processing in a Pure Environment

- How does a vacuum furnace prevent heat transfer and contamination? Achieve Ultimate Material Purity

- What is the process of vacuum heat treatment? Achieve Superior Metallurgical Properties

- Why use a vacuum furnace? Achieve Unparalleled Material Purity and Process Control