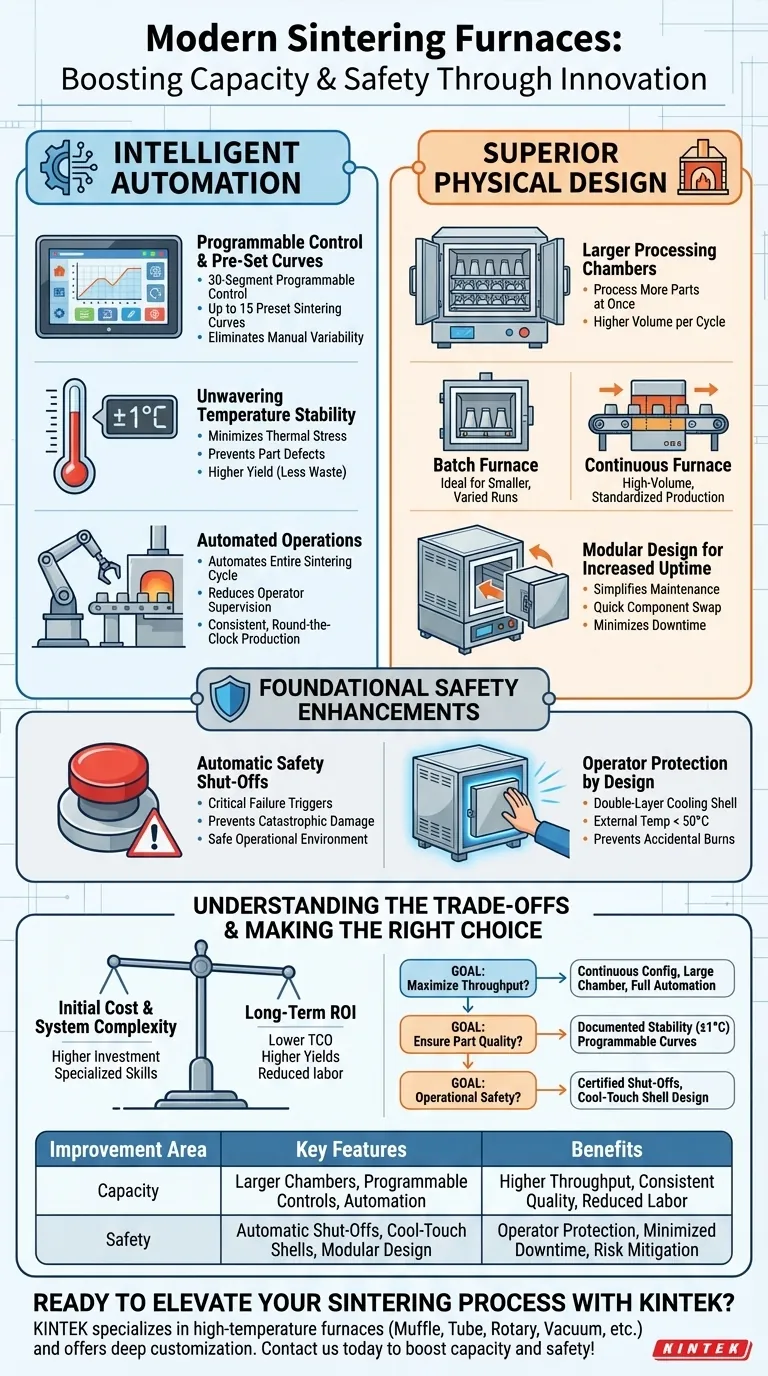

In short, modern sintering furnaces have seen significant capacity and safety improvements driven by two primary forces: intelligent automation and superior physical design. These advancements include larger processing chambers, highly precise control systems with programmable curves, and integrated safety mechanisms like automatic shut-offs and cool-touch external shells.

The core evolution in sintering furnaces is not just about making them bigger or safer in isolation. It's about integrating intelligent software controls with robust physical engineering to transform sintering from a high-variable art into a predictable, efficient, and reliable manufacturing science.

Boosting Capacity Through Intelligent Automation

The most significant leaps in productivity come from the furnace's ability to think and act with minimal human intervention. This ensures speed, repeatability, and a higher yield of quality parts.

Programmable Control and Pre-Set Curves

Modern furnaces feature advanced controllers, often operated via a simple color touchscreen. With capabilities like 30-segment programmable control and up to 15 preset sintering curves, operators can execute complex, multi-stage heating and cooling profiles with perfect consistency.

This dramatically reduces setup time and eliminates the variability that comes from manual adjustments, ensuring every batch is processed under ideal conditions.

Unwavering Temperature Stability

A key factor in production capacity is yield—the number of usable parts per cycle. Modern furnaces achieve exceptional temperature stability, often holding within ±1°C of the setpoint.

This precision minimizes thermal stress and prevents part defects, warping, or incomplete sintering. Fewer rejected parts means a higher effective output and less wasted material and energy.

Automated Operations

Intelligent control systems automate the entire sintering cycle, from initial pump-down in vacuum models to the final cooling stage. This reduces the need for constant operator supervision, freeing up skilled labor for other value-added tasks and enabling more consistent, round-the-clock production.

Enhancing Capacity with Superior Physical Design

Beyond the control system, the physical construction of the furnace is engineered for higher throughput and greater operational uptime.

Larger Processing Chambers

The most direct way to increase capacity is to process more parts at once. Manufacturers now offer furnaces with significantly larger internal chambers, allowing for a higher volume of product in a single sintering cycle, which directly increases productivity.

Batch vs. Continuous Configurations

Flexibility in design allows facilities to match the furnace to their specific workflow. Batch furnaces are ideal for smaller, varied production runs, while continuous furnaces are designed for high-volume, standardized manufacturing where parts move constantly through the heat zones.

Choosing the right configuration is critical for optimizing production flow and maximizing plant capacity.

Modular Design for Increased Uptime

Modern furnaces often feature a modular design. This simplifies maintenance, repair, and troubleshooting significantly.

When a component fails, it can be quickly swapped out, minimizing equipment downtime. More uptime directly translates to more production time and higher overall capacity.

Foundational Safety Enhancements

Alongside performance, operator safety has become a central design pillar. Modern furnaces integrate multiple layers of protection, moving from reactive alerts to proactive, automated safety systems.

Automatic Safety Shut-Offs

These furnaces are equipped with mechanisms that automatically shut down the system in the event of a critical failure. This includes triggers for over-temperature, over-pressure, or cooling water interruptions, preventing catastrophic equipment damage and ensuring a safe operational environment.

Operator Protection by Design

Physical engineering plays a crucial role in daily safety. Features like a double-layer cooling shell keep the furnace's external surface temperature below 50°C, even when internal temperatures are extreme. This design prevents accidental burns and makes the immediate work area safer for personnel.

Understanding the Trade-offs

While these advancements offer clear benefits, they require careful consideration.

Initial Cost vs. Long-Term ROI

Furnaces equipped with advanced automation, precision controls, and robust safety features carry a higher initial investment. The trade-off is a significantly lower total cost of ownership over the equipment's lifespan, driven by higher yields, reduced labor, lower energy consumption, and greater uptime.

System Complexity and Maintenance

While modular designs simplify repairs, the underlying systems are more complex than their predecessors. Troubleshooting advanced electronics or control software may require technicians with specialized skills, a factor to consider for maintenance planning and training.

Making the Right Choice for Your Goal

The best furnace depends entirely on your primary operational driver.

- If your primary focus is maximizing throughput: Prioritize a continuous configuration with the largest possible chamber and fully automated controls to minimize cycle and loading times.

- If your primary focus is ensuring part quality: Invest in a system with documented temperature stability (±1°C) and highly programmable sintering curves.

- If your primary focus is operational safety and risk mitigation: Select a furnace with certified automatic shut-offs and a cool-touch external shell design.

Ultimately, these modern improvements allow you to treat sintering as a precise and controlled step in your manufacturing process.

Summary Table:

| Improvement Area | Key Features | Benefits |

|---|---|---|

| Capacity | Larger chambers, programmable controls, automation | Higher throughput, consistent quality, reduced labor |

| Safety | Automatic shut-offs, cool-touch shells, modular design | Operator protection, minimized downtime, risk mitigation |

Ready to elevate your sintering process with cutting-edge furnace solutions? KINTEK specializes in high-temperature furnaces, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Leveraging our exceptional R&D and in-house manufacturing, we offer deep customization to precisely meet your unique experimental and production needs. Contact us today to discuss how our advanced solutions can boost your capacity, enhance safety, and deliver superior results for your laboratory or manufacturing facility!

Visual Guide

Related Products

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- How is the structure of a rotary tube furnace characterized? Discover Its Key Components and Benefits

- How does the heating process work in rotary tube furnaces? Achieve Uniform Heat for Powders and Granules

- How do rotary tube furnaces contribute to material science and chemical engineering? Unlock Precision in Material Processing

- What are the key advantages of rotary tube furnaces? Achieve Superior Uniformity and Efficiency for Your Materials

- How does a rotary tube furnace operate? Master Continuous Heating for Uniform Results