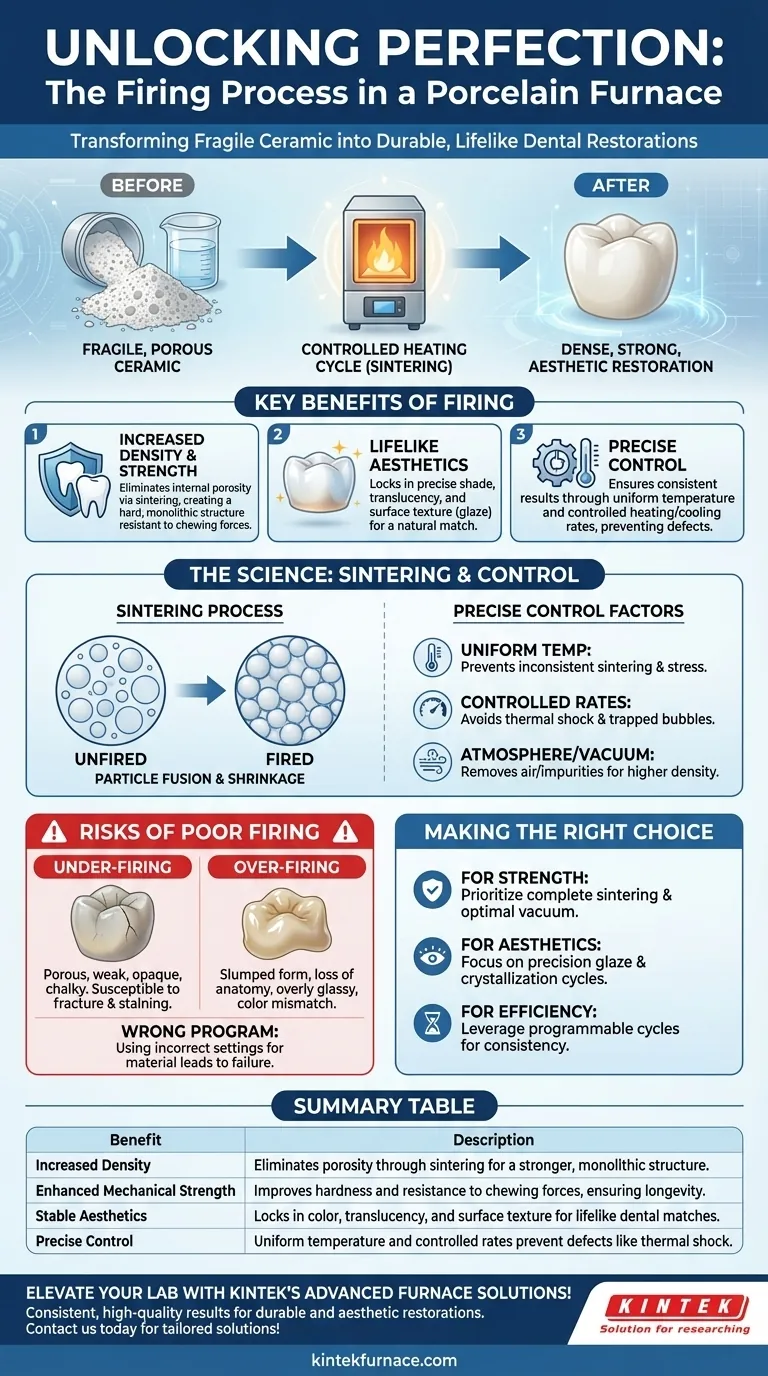

At its core, the firing process in a porcelain furnace is a transformative step that converts a fragile, porous ceramic application into a final, high-strength dental restoration. This controlled heating cycle is responsible for giving the ceramic its crucial properties, including optimal density, mechanical strength, and stable, lifelike color.

The fundamental purpose of firing is not merely to heat the ceramic, but to initiate sintering—a process that fuses individual ceramic particles at a microscopic level. This eliminates internal porosity, creating a dense, monolithic structure that is both strong and aesthetically pleasing.

The Transformation: From Powder to Prosthesis

A raw dental ceramic, whether in powder/liquid form or a milled block, lacks the physical properties required for clinical function. The firing process creates a precisely controlled environment to induce the necessary chemical and physical changes.

The Science of Sintering

Sintering is the technical term for what occurs inside the furnace. As the temperature rises, the individual particles of the ceramic material begin to bond and fuse together.

This fusion dramatically reduces the space between particles, effectively shrinking the material and eliminating the voids or pores that were present in its unfired state. The result is a significantly denser and stronger final object.

Achieving Optimal Density and Hardness

The primary mechanical benefit of firing is the increase in density. A porous material is inherently weak, as voids act as stress concentrators where fractures can begin.

By eliminating these voids through sintering, the furnace creates a restoration that is substantially harder and more resistant to the forces of chewing. This ensures the long-term clinical success and longevity of the crown, veneer, or bridge.

Locking In Color and Aesthetics

Firing is also critical for achieving the final aesthetic result. The process develops the ceramic's prescribed shade, translucency, and surface texture (glaze).

The specific temperatures and hold times are designed to mature the color pigments and opacifiers within the material, ensuring the final restoration is a precise match to the patient's natural teeth and remains stable over time.

Why Precise Control is Non-Negotiable

A porcelain furnace is far more than a simple oven. Its value lies in its ability to manage every variable of the heating and cooling process with extreme precision.

Uniform Temperature Distribution

The most critical factor is even temperature distribution throughout the firing chamber. If one part of a restoration heats faster than another, the sintering will be inconsistent.

This leads to internal stresses, weak spots, or visible defects in the final product. Modern furnaces are engineered to ensure every surface of the restoration reaches the target temperature at the same time.

Controlled Heating and Cooling Rates

How quickly the furnace heats up and cools down is just as important as the peak temperature. Ramping the temperature too quickly can cause surface layers to fuse before internal gases have escaped, trapping bubbles.

Likewise, cooling too rapidly induces thermal shock, creating micro-fractures that compromise the restoration's structural integrity, even if they aren't immediately visible.

Atmosphere and Vacuum Management

Many firing cycles incorporate a vacuum. A vacuum is pulled in the initial heating stages to remove air and impurities from between the ceramic particles.

This allows the particles to achieve more intimate contact before they begin to fuse, resulting in a restoration with even greater density and fewer internal defects.

Understanding the Risks of Poor Firing

When the firing process is not executed correctly, the quality of the final restoration is severely compromised. These are not minor issues; they directly impact clinical outcomes.

The Danger of Under-Firing

If the furnace fails to reach the correct temperature or hold it for the required duration, the ceramic will be under-sintered. The resulting restoration will be porous, weak, opaque, and may appear chalky. It will be highly susceptible to fracture and staining.

The Problem of Over-Firing

Excessive heat or time causes the ceramic to "slump" and lose its carefully sculpted anatomical form. The material can also appear overly glassy and translucent, failing to match the patient's natural dentition. This renders the restoration aesthetically unacceptable.

The Impact of Incorrect Program Selection

Modern ceramics are highly specialized. Using a firing program intended for a different material is a common source of failure. Each material has a unique profile for temperature, hold times, and vacuum levels, which must be followed exactly as specified by the manufacturer.

Making the Right Choice for Your Goal

Achieving predictable, high-quality results depends on using the furnace's capabilities to meet the specific demands of the restoration.

- If your primary focus is strength and longevity: Prioritize complete sintering by using the correct manufacturer program and ensuring the furnace's vacuum system is functioning optimally to maximize density.

- If your primary focus is high-end aesthetics: Pay close attention to the precision of your glaze and crystallization cycles, as these final firings determine the ultimate shade, translucency, and surface luster.

- If your primary focus is operational efficiency: Fully leverage the programmable cycles of your furnace to ensure every case is fired with absolute consistency, minimizing remakes and saving valuable technician time.

Ultimately, mastering the principles of the firing process transforms the furnace from a simple piece of equipment into a precision instrument for creating durable and lifelike dental art.

Summary Table:

| Benefit | Description |

|---|---|

| Increased Density | Eliminates porosity through sintering for a stronger, monolithic structure. |

| Enhanced Mechanical Strength | Improves hardness and resistance to chewing forces, ensuring longevity. |

| Stable Aesthetics | Locks in color, translucency, and surface texture for lifelike dental matches. |

| Precise Control | Uniform temperature and controlled rates prevent defects like thermal shock. |

Elevate your dental lab's precision and efficiency with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. Our deep customization capabilities ensure they meet your unique experimental needs, delivering consistent, high-quality results for durable and aesthetic dental restorations. Contact us today to discuss how our tailored solutions can transform your workflow and outcomes!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What aspects of a dental restoration are directly impacted by the choice of a dental sintering furnace? Ensure Fit, Strength & Longevity

- How often should dental furnaces be calibrated? Ensure Precision for Perfect Restorations

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision

- Why is accurate temperature control important in dental furnaces? Ensure Perfect Restorations Every Time