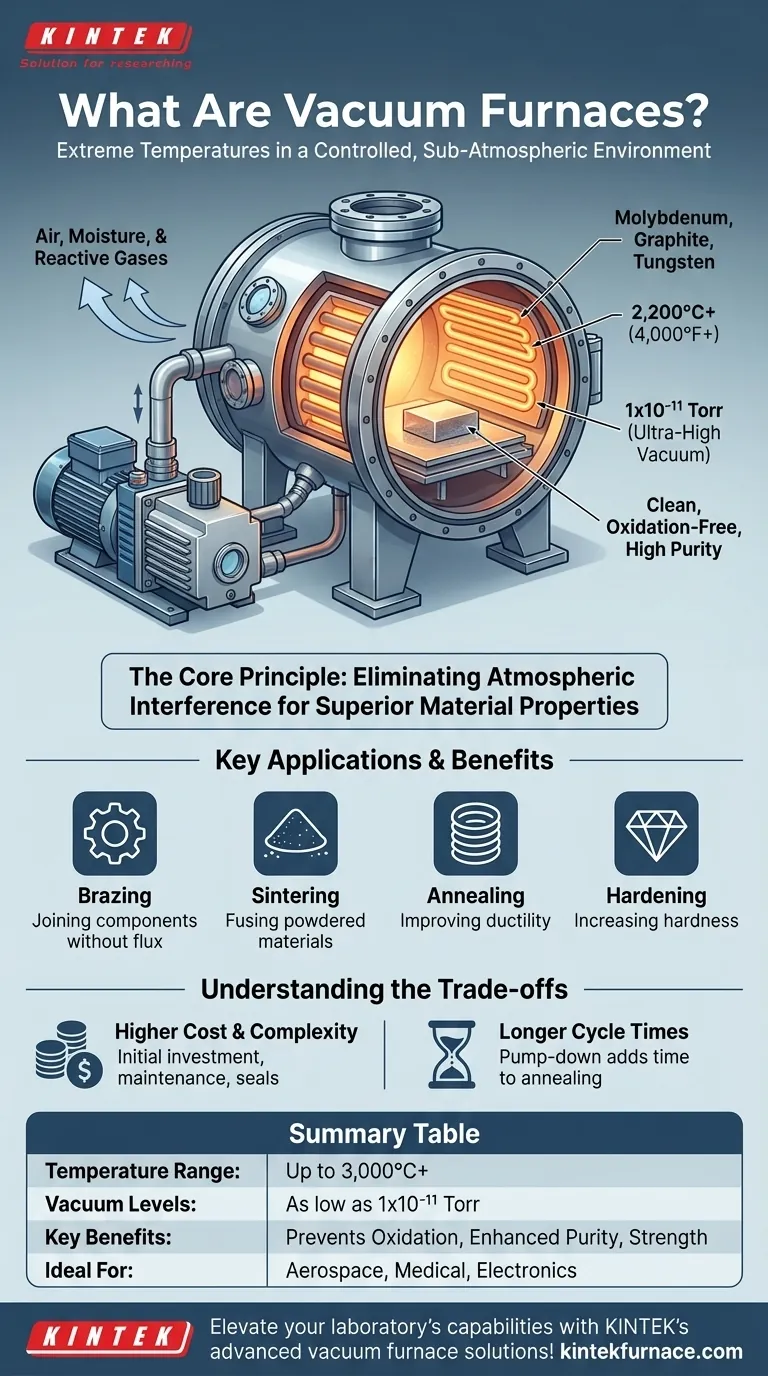

At its core, a vacuum furnace is a specialized chamber that heats materials to extreme temperatures in a controlled, sub-atmospheric environment. By removing air and other reactive gases before heating, these furnaces prevent oxidation and contamination, which is critical for processing high-performance materials. They operate under a wide range of conditions, with temperatures that can exceed 2,200°C (4,000°F) and vacuum levels as low as 1x10⁻¹¹ Torr.

The true purpose of a vacuum furnace isn't just to generate heat; it's to create an ultra-pure environment. By eliminating atmospheric interference, it allows for thermal processes that result in materials with superior strength, cleanliness, and structural integrity.

How a Vacuum Furnace Achieves Superior Results

A vacuum furnace's unique capabilities stem from its ability to precisely control the environment in which a material is heated and cooled.

The Core Principle: Removing the Atmosphere

The process begins by placing materials inside a sealed, robust chamber. A sophisticated system of pumps then removes the air and moisture from this chamber.

This critical step eliminates oxygen and other reactive gases that would otherwise cause oxidation, discoloration, or contamination at high temperatures. The result is an exceptionally clean, bright surface finish on the final part.

Creating the Vacuum

The level of vacuum is a key operating parameter. For many industrial applications, a medium or high vacuum is sufficient.

However, for sensitive electronics, medical, or aerospace components, furnaces can achieve ultra-high vacuum levels, creating an environment that is almost a perfect void. This ensures absolutely no atmospheric interference during the process.

Reaching Extreme Temperatures

Once the vacuum is established, powerful heating elements heat the workload. These elements are often made from high-temperature materials like molybdenum, graphite, or tungsten.

These systems can achieve exceptionally uniform temperatures, often ranging from 800°C to over 3,000°C (1,500°F to 5,400°F), with precise digital control ensuring the material is heated exactly as required.

Ensuring Process Repeatability

Modern vacuum furnaces are fully automated. The entire cycle—from pumping down the vacuum to the specific heating profile and controlled cooling or quenching—is managed by a computer.

This automation guarantees that every part processed under a specific recipe receives the exact same treatment, ensuring high repeatability and consistent quality.

The Key Applications and Benefits

The controlled environment of a vacuum furnace unlocks processes and material properties that are impossible to achieve in a conventional atmospheric furnace.

Purity and Enhanced Properties

By preventing reactions with the atmosphere, vacuum furnaces produce parts with higher purity and enhanced mechanical properties. This is essential for superalloys, titanium, and advanced ceramics used in demanding applications.

During heating, the vacuum can also help pull out trapped impurities or residual gases from within the material itself, a process known as outgassing, further improving its quality.

Versatility in Thermal Processing

Vacuum furnaces are not limited to a single task. They are highly versatile and used for a wide range of critical processes, including:

- Brazing: Joining components with a filler metal, creating strong, clean joints without the use of flux.

- Sintering: Fusing powdered materials together to create a solid mass.

- Annealing: Softening metals to improve ductility and reduce internal stresses.

- Hardening: Heating and then rapidly cooling a material to increase its hardness.

Understanding the Trade-offs

While incredibly powerful, vacuum furnaces are not the solution for every thermal processing need. Their precision and capabilities come with specific considerations.

Higher Initial Cost and Complexity

Vacuum systems are inherently more complex than their atmospheric counterparts. The need for robust chambers, high-performance pumps, seals, and advanced control systems results in a significantly higher initial investment and maintenance overhead.

Longer Cycle Times

The process of creating a vacuum, known as the "pump-down," adds time to the beginning of every cycle. For applications where speed is paramount and oxidation is not a major concern, a traditional continuous-belt furnace may be more efficient.

Material Compatibility

Certain materials can be problematic in a vacuum. Materials with high vapor pressures can outgas excessively, potentially contaminating the furnace interior or other parts in the load. Careful evaluation of the material being processed is essential.

Making the Right Choice for Your Goal

Selecting the right furnace technology depends entirely on the requirements of your material and final product.

- If your primary focus is material purity and performance: A vacuum furnace is essential for processing sensitive alloys, medical-grade metals, or aerospace components where oxidation is unacceptable.

- If your primary focus is high-strength joining: The ultra-clean environment of a vacuum furnace is ideal for brazing, as it prevents oxide formation that would weaken the joint.

- If your primary focus is cost-effective, high-volume treatment of common steels: A traditional atmospheric furnace often provides a more economical and faster solution when slight surface oxidation is tolerable.

Ultimately, choosing a vacuum furnace is a strategic decision to prioritize material integrity and process control over operational simplicity.

Summary Table:

| Aspect | Details |

|---|---|

| Temperature Range | Up to 3,000°C (5,400°F) or higher |

| Vacuum Levels | As low as 1x10⁻¹¹ Torr |

| Key Benefits | Prevents oxidation, ensures purity, enhances material strength |

| Common Applications | Brazing, sintering, annealing, hardening |

| Ideal For | Aerospace, medical, electronics, and high-performance alloys |

Elevate your laboratory's capabilities with KINTEK's advanced vacuum furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace systems, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we can precisely meet your unique experimental requirements, delivering superior purity, repeatability, and performance for materials like superalloys and ceramics. Don't let contamination hold you back—contact us today to discuss how our tailored solutions can optimize your thermal processes and drive innovation in your projects!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What are the different classifications of vacuum furnaces based on pressure range? Explore High-Vacuum vs. UHV for Your Lab

- What is the purpose of transferring high-temperature glass to a preheated annealing furnace? Ensuring Sample Integrity

- What are the key design features of a vacuum graphitizing furnace? Achieving High-Purity Graphitization

- What is the working principle of a vacuum carburizing furnace? Achieve Superior Surface Hardening for Steel Parts

- What are the advantages of using vacuum filtration systems for calcium-based perrhenates? Expert Stability Guide

- What is the significance of an automated pressure control system in a vacuum chamber? Optimize Plasma Nitriding

- What industries commonly use vacuum sintering furnaces? Unlock Purity and Strength for High-Tech Applications

- Why is high-purity nitrogen (N2) required during the selenization of electrode materials? Expert Furnace Insights