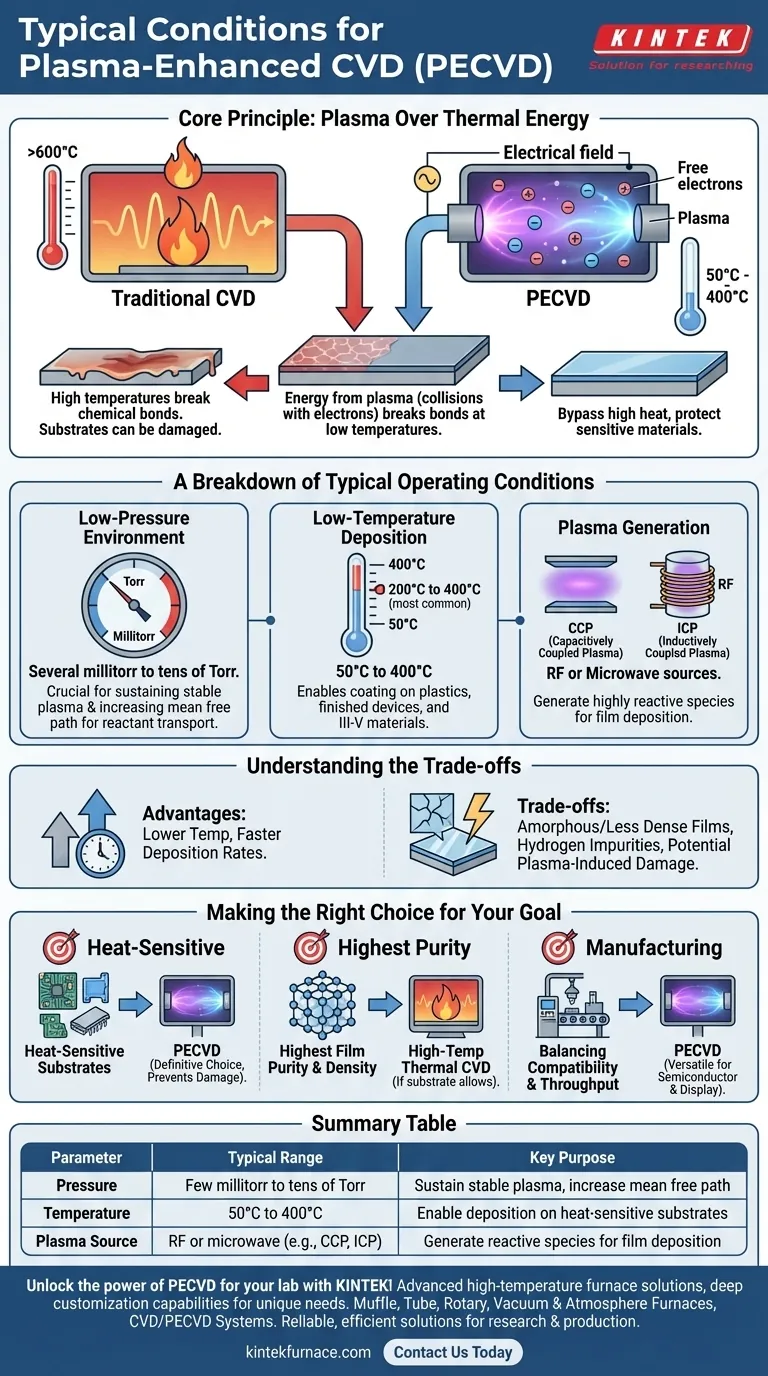

At its core, Plasma-Enhanced Chemical Vapor Deposition (PECVD) is defined by its use of low pressures and low temperatures to deposit thin films. The process typically operates in a pressure range from a few millitorr to tens of Torr, with substrate temperatures generally falling between 50°C and 400°C. This unique operating window is what separates PECVD from conventional, high-temperature CVD methods.

The fundamental advantage of PECVD is its ability to use energy from a plasma, rather than high heat, to drive the chemical reactions needed for film deposition. This makes it possible to coat materials that would be damaged or destroyed by the intense heat of traditional processes.

The Core Principle: Plasma Over Thermal Energy

To understand why these conditions are used, you must first grasp the central purpose of PECVD: to bypass the need for high thermal energy.

What is PECVD?

PECVD is a thin film deposition process that uses an electrical field to generate a plasma, which is a state of matter containing highly reactive ions, radicals, and free electrons. These energized particles interact with precursor gases introduced into the chamber, causing them to decompose and deposit as a solid film onto a substrate.

How Plasma Replaces Heat

In traditional Chemical Vapor Deposition (CVD), high temperatures (often >600°C) are required to provide enough energy to break the chemical bonds of the precursor gases.

In PECVD, the energy to break these bonds comes from collisions with high-energy electrons within the plasma, not from heat. This allows the chemical reactions to occur at a much lower temperature, preserving the integrity of the underlying substrate.

A Breakdown of Typical Operating Conditions

Each parameter in a PECVD process is carefully controlled to sustain the plasma and achieve the desired film properties.

Low-Pressure Environment

PECVD is fundamentally a low-pressure or vacuum-based process, typically operating from several millitorr to tens of Torr.

This low pressure is critical for two reasons. First, it is necessary to ignite and sustain a stable plasma. Second, it increases the "mean free path"—the average distance a particle travels before colliding with another—which allows ions and reactive species to travel to the substrate surface without premature reactions in the gas phase.

Low-Temperature Deposition

The most significant feature of PECVD is its low-temperature range, most commonly between 200°C and 400°C, though processes as low as 50°C are possible.

This is the key advantage of the technique. It enables the deposition of high-quality dielectric films, such as silicon nitride (SiN) or silicon dioxide (SiO₂), onto substrates that cannot tolerate high heat, including plastics, finished semiconductor devices with metal layers, and temperature-sensitive III-V materials.

Plasma Generation

The plasma itself is typically generated using a radio frequency (RF) or microwave source. The two most common methods are:

- Capacitively Coupled Plasma (CCP): Uses parallel plate electrodes to create a plasma, common for depositing insulating films.

- Inductively Coupled Plasma (ICP): Uses an RF-powered coil to induce a plasma, which can achieve higher plasma densities and faster deposition rates.

Understanding the Trade-offs

While powerful, the low-temperature nature of PECVD introduces specific trade-offs that are important to recognize.

Film Quality and Impurities

Because the deposition occurs at lower temperatures, the resulting films are often amorphous or less dense than their high-temperature counterparts.

For example, PECVD-deposited silicon nitride films inherently contain a significant amount of hydrogen. This incorporated hydrogen can affect the film's electrical properties, stress, and thermal stability, which must be accounted for in device design.

Potential for Plasma-Induced Damage

The energetic ions bombarding the substrate surface, while essential for the deposition reaction, can also cause physical or electrical damage. This is a critical consideration when depositing films on highly sensitive electronic components, such as the gate of a transistor.

Making the Right Choice for Your Goal

Selecting a deposition method depends entirely on the requirements of your substrate and the desired final film properties.

- If your primary focus is depositing on heat-sensitive substrates: PECVD is the definitive and often only choice, as its low-temperature process prevents substrate damage.

- If your primary focus is achieving the highest possible film purity and density: High-temperature thermal CVD may be superior, provided your substrate can withstand the heat.

- If your primary focus is balancing device compatibility and throughput for manufacturing: PECVD offers a versatile and robust solution used widely across the semiconductor and display industries.

Ultimately, understanding these operating conditions empowers you to choose the right tool for your specific engineering challenge.

Summary Table:

| Parameter | Typical Range | Key Purpose |

|---|---|---|

| Pressure | Few millitorr to tens of Torr | Sustain stable plasma and increase mean free path |

| Temperature | 50°C to 400°C | Enable deposition on heat-sensitive substrates |

| Plasma Source | RF or microwave (e.g., CCP, ICP) | Generate reactive species for film deposition |

Unlock the power of PECVD for your lab with KINTEK! Leveraging exceptional R&D and in-house manufacturing, we provide advanced high-temperature furnace solutions tailored for diverse laboratories. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to precisely meet your unique experimental needs. Whether you're working with heat-sensitive substrates or require optimized film properties, KINTEK delivers reliable, efficient solutions. Contact us today to discuss how our expertise can enhance your research and production processes!

Visual Guide

Related Products

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

People Also Ask

- What is resistance heating and how is it classified? Discover the Best Method for Your Thermal Needs

- What are the advantages of using CVD? Achieve High-Purity, Conformal Thin Films for Your Applications

- What is plasma-deposited silicon nitride, and what are its properties? Discover Its Role in Solar Cell Efficiency

- What parameters control the quality of PECVD-deposited films? Master Key Variables for Superior Film Properties

- How is silicon dioxide deposited from tetraethylorthosilicate (TEOS) in PECVD? Achieve Low-Temperature, High-Quality SiO2 Films