In short, ceramic heating elements are widely used in applications requiring uniform, high-temperature, and safe heating. Their most common uses are found in industrial processing like plastic extrusion, precision tools such as soldering irons, high-temperature furnaces, and efficient HVAC systems.

The decision to use a ceramic heating element is not just about reaching a certain temperature. It's about leveraging a unique combination of thermal stability, electrical insulation, and energy efficiency that makes it the superior choice for applications where safety and reliability are paramount.

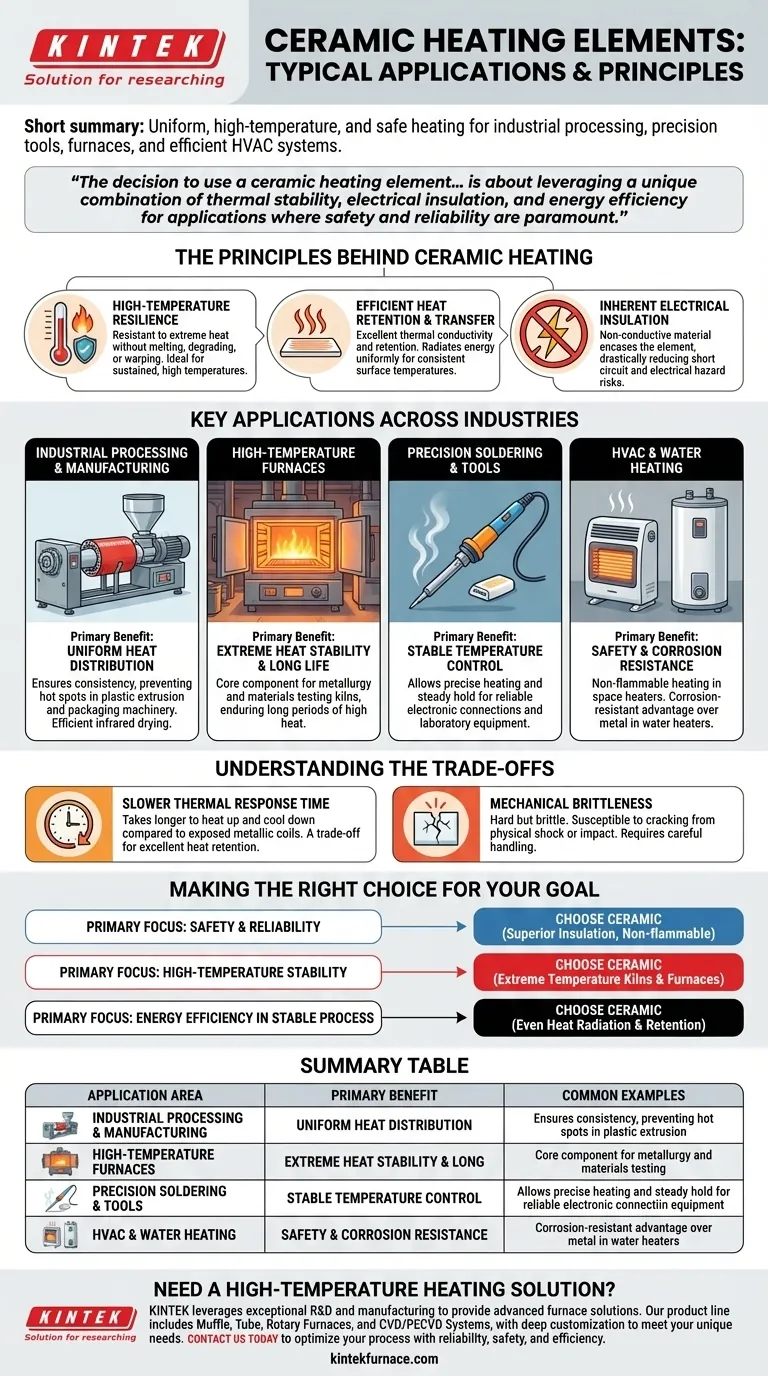

The Principles Behind Ceramic Heating

To understand where ceramic heaters excel, you must first understand their fundamental properties. These components work by converting electrical energy into thermal energy through an advanced ceramic material.

High-Temperature Resilience

Ceramic materials are exceptionally resistant to heat. They can operate at very high temperatures without melting, degrading, or warping, unlike many metallic alternatives.

This resilience makes them ideal for processes that demand sustained, extreme heat.

Efficient Heat Retention and Transfer

Ceramics possess excellent thermal conductivity and retention. Once heated, they hold that energy efficiently and radiate it uniformly.

This quality ensures consistent surface temperatures, which is critical for sensitive processes, and reduces the energy required to maintain a set point.

Inherent Electrical Insulation

A defining characteristic of ceramic is its inability to conduct electricity. The heating element is safely encased within this insulating material.

This design dramatically reduces the risk of short circuits and electrical hazards, enhancing operational safety, especially in high-temperature or demanding environments.

Key Applications Across Industries

The unique properties of ceramic heaters make them the go-to solution in several specific fields. Each application leverages a different primary benefit of the material.

Industrial Processing and Manufacturing

In plastic extrusion and packaging machinery, uniform heat is critical to ensure product quality. Ceramic band heaters provide this consistency, preventing hot spots that could damage materials.

For industrial drying processes, ceramic infrared emitters are used to efficiently apply heat over large surface areas without direct contact.

High-Temperature Furnaces

Metallurgy and materials testing often require furnaces that can reach and hold extreme temperatures for long periods.

Ceramic heating elements are the core component in these furnaces, providing the necessary high-temperature stability and long service life required for such demanding work.

Precision Soldering and Tools

Soldering irons require precise and stable temperature control to create reliable electronic connections without damaging components.

Ceramic heaters allow these tools to heat up to a specific temperature and hold it steady, while their internal insulation ensures operator safety.

HVAC and Water Heating

In modern space heaters and some HVAC systems, ceramic elements provide safe, efficient, and non-flammable heating. Because they don't glow red-hot like some metal coils, they reduce fire risk.

For water heaters, the material's corrosion resistance offers a significant durability advantage over metal elements that can rust and fail over time.

Understanding the Trade-offs

While highly effective, ceramic heaters are not the universal solution for every heating need. Understanding their limitations is key to making an informed decision.

Slower Thermal Response Time

Compared to an exposed metallic coil, a ceramic heater generally takes longer to heat up and cool down. This is a direct trade-off for its excellent heat retention.

For applications requiring rapid temperature cycling, a different technology might be more suitable.

Mechanical Brittleness

Ceramic is a hard but brittle material. Unlike ductile metals that can bend, a ceramic element can crack or shatter if subjected to significant physical shock or impact.

Care must be taken during installation and maintenance to avoid mechanical stress.

Making the Right Choice for Your Goal

Selecting the right heating technology depends entirely on your primary objective.

- If your primary focus is safety and reliability: Choose ceramic for its superior electrical insulation and non-flammable properties, especially in user-facing products or critical processes.

- If your primary focus is high-temperature stability: Ceramic is the definitive choice for applications like furnaces and industrial kilns that operate at extreme temperatures.

- If your primary focus is energy efficiency in a stable process: Ceramic's ability to retain and radiate heat evenly makes it highly efficient for applications that need to maintain a set temperature for extended periods.

Ultimately, choosing a ceramic heater is a strategic decision for applications where precision, safety, and long-term durability outweigh the need for instant-on heating.

Summary Table:

| Application Area | Primary Benefit of Ceramic Heater | Common Examples |

|---|---|---|

| Industrial Processing | Uniform Heat Distribution | Plastic Extrusion, Packaging Machinery |

| High-Temperature Furnaces | Extreme Heat Stability & Long Life | Metallurgy, Materials Testing Kilns |

| Precision Tools | Stable Temperature Control | Soldering Irons, Laboratory Equipment |

| HVAC & Water Heating | Safety & Corrosion Resistance | Space Heaters, Commercial Water Heaters |

Need a High-Temperature Heating Solution Tailored to Your Unique Requirements?

At KINTEK, we leverage our exceptional R&D and in-house manufacturing capabilities to provide diverse laboratories and industries with advanced high-temperature furnace solutions. Our product line—including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—is complemented by strong deep customization capabilities to precisely meet your unique experimental and processing needs, whether you require the uniform heating of a ceramic element or another specialized solution.

Contact us today to discuss how we can optimize your heating process with reliability, safety, and efficiency.

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- Why are silicon carbide heating elements essential in high-temperature industries? Unlock Reliable, Extreme Heat Solutions

- What are the properties and capabilities of Silicon Carbide (SiC) as a heating element? Unlock Extreme Heat and Durability

- Why is silicon carbide resistant to chemical reactions in industrial furnaces? Unlock Durable High-Temp Solutions

- What are the advantages of using high purity green silicon carbide powder in heating elements? Boost Efficiency and Lifespan

- What is the maximum temperature silicon carbide heating elements can withstand? Key Factors for Longevity and Performance