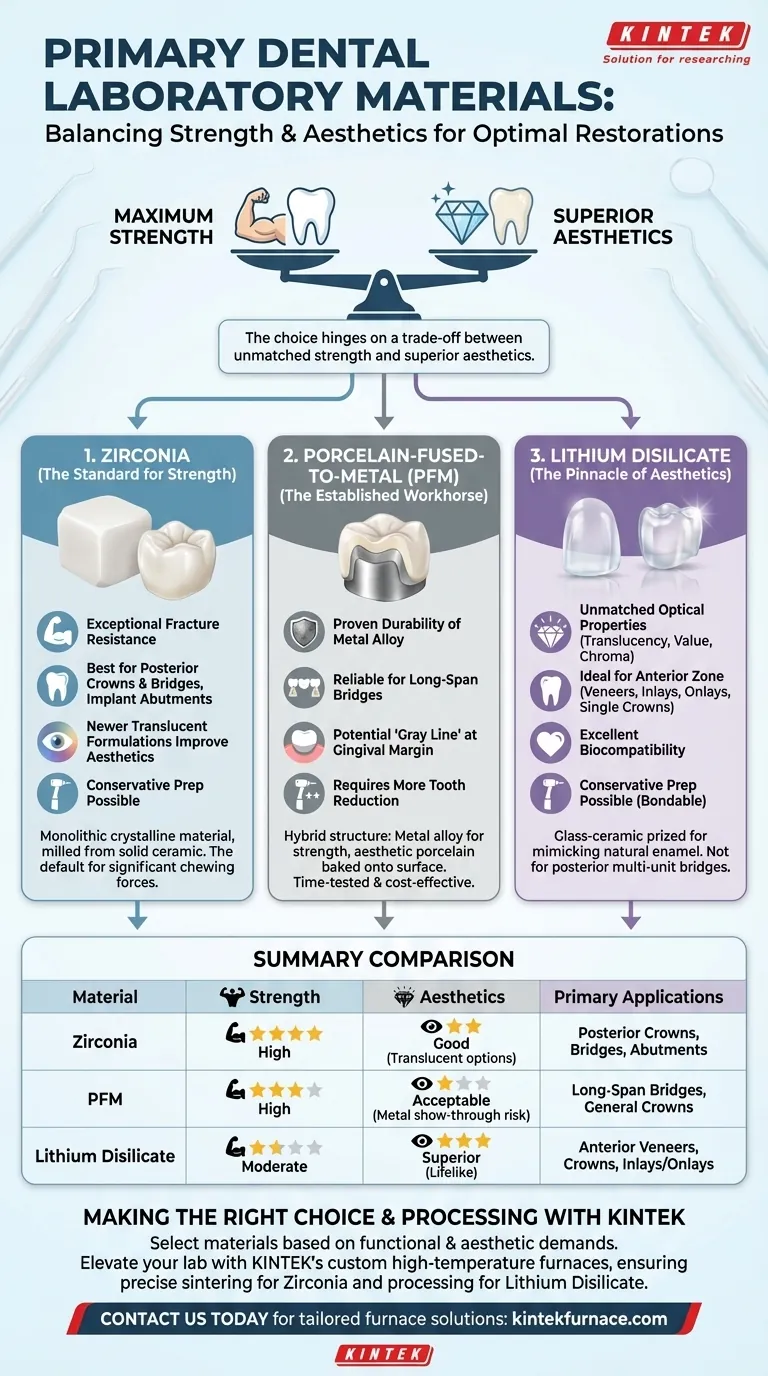

The three primary materials used in modern dental laboratories are zirconia, porcelain-fused-to-metal (PFM), and lithium disilicate. Each is selected based on a precise balance of strength, aesthetics, and the specific clinical demands of the restoration, such as its location in the mouth and the forces it must endure.

The choice of a dental restorative material is not a matter of old versus new, but of selecting the right tool for the job. Your decision hinges on a fundamental trade-off: the unmatched strength of zirconia, the superior aesthetics of lithium disilicate, and the proven reliability of PFM.

Zirconia: The Standard for Strength

Zirconia, a high-strength ceramic (zirconium dioxide), has become the default material for restorations that must withstand significant chewing forces.

What is Zirconia?

Zirconia is a monolithic crystalline material, meaning it is milled from a solid block of the ceramic. This composition gives it exceptional fracture resistance, far surpassing that of other all-ceramic options.

Primary Applications

Due to its robust nature, zirconia is the material of choice for posterior crowns and bridges, where occlusal forces are highest. It is also frequently used for durable implant abutments.

Aesthetic Considerations

While incredibly strong, traditional zirconia can be opaque, which may not be ideal for highly visible anterior teeth. However, newer formulations like translucent zirconia have significantly improved aesthetics, making it a more versatile option than ever before.

Lithium Disilicate: The Pinnacle of Aesthetics

When a restoration must blend seamlessly with natural teeth, lithium disilicate (often known by the brand name E.max) is the premier choice.

What is Lithium Disilicate?

This is a glass-ceramic material prized for its optical properties. Its ability to mimic the translucency, value, and chroma of natural enamel is unmatched by other restorative materials.

Primary Applications

Lithium disilicate excels in the anterior aesthetic zone. It is the ideal material for veneers, inlays, onlays, and single crowns on front teeth where appearance is the highest priority.

Strength Profile

While strong enough for single crowns anywhere in the mouth, lithium disilicate is not as fracture-resistant as zirconia. Therefore, it is generally not recommended for multi-unit bridges in the posterior region.

Porcelain-Fused-to-Metal (PFM): The Established Workhorse

For decades, the PFM was the gold standard, and it remains a reliable and relevant option in many clinical situations.

The Hybrid Structure

A PFM restoration consists of a cast metal alloy substructure that provides strength, with a layer of aesthetic porcelain baked onto its surface.

Why It's Still Used

PFMs combine the proven durability of metal with the acceptable aesthetics of porcelain. They are a time-tested, predictable, and often more cost-effective solution, especially for long-span bridges where metal's strength is an advantage.

Understanding the Trade-offs

No single material is perfect for every situation. The decision requires a clear understanding of the compromises involved.

Strength vs. Aesthetics

This is the central trade-off. Zirconia offers maximum strength at the cost of some translucency, while lithium disilicate offers maximum aesthetics with less fracture resistance. PFM sits in the middle, offering good strength but with aesthetic limitations.

Biocompatibility and Tissue Response

Both zirconia and lithium disilicate are highly biocompatible and kind to the surrounding gum tissue. PFMs can sometimes lead to a dark line at the gingival margin (the "gray line") if recession occurs, and in rare cases, patients may have an allergy to the base metal alloy.

Preparation Requirements

All-ceramic restorations like zirconia and lithium disilicate can often be bonded to the tooth, which may allow for more conservative tooth preparation. PFMs typically require more tooth reduction to create space for both the metal and the porcelain layers.

Making the Right Choice for Your Goal

Your material selection should be a deliberate decision guided by the specific functional and aesthetic demands of the case.

- If your primary focus is maximum strength for posterior cases: Choose zirconia for its unmatched durability under high occlusal forces.

- If your primary focus is superior aesthetics for the anterior region: Select lithium disilicate for its lifelike translucency and excellent color integration.

- If your primary focus is a proven, cost-effective solution for bridges: Consider PFM as a reliable workhorse that combines the strength of metal with functional aesthetics.

Understanding the distinct profile of each material empowers you to deliver predictable, functional, and beautiful patient outcomes.

Summary Table:

| Material | Key Characteristics | Primary Applications |

|---|---|---|

| Zirconia | High strength, fracture-resistant | Posterior crowns, bridges, implant abutments |

| PFM | Reliable, cost-effective, hybrid structure | Long-span bridges, general crowns |

| Lithium Disilicate | Superior aesthetics, excellent translucency | Anterior veneers, inlays, onlays, single crowns |

Elevate Your Dental Laboratory with Custom High-Temperature Furnaces

At KINTEK, we understand that precise material processing is key to creating durable and beautiful dental restorations. Leveraging exceptional R&D and in-house manufacturing, we provide dental laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental and production needs.

Whether you're sintering zirconia for maximum strength or processing lithium disilicate for superior aesthetics, our furnaces ensure consistent results and enhanced efficiency. Contact us today via our contact form to discuss how we can tailor a solution for your laboratory!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- Why is using a universal setting for all materials in a dental furnace a mistake? Master Precision Sintering for Perfect Restorations

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations

- What aspects of a dental restoration are directly impacted by the choice of a dental sintering furnace? Ensure Fit, Strength & Longevity