At their core, Silicon Carbide (SiC) heating elements are defined by a unique combination of three thermal properties: an extremely high maximum operating temperature, excellent thermal conductivity, and a very low coefficient ofthermal expansion. This trifecta allows them to deliver intense, uniform heat with exceptional stability and reliability, far surpassing the capabilities of many traditional metallic heating elements.

The true value of SiC heating elements isn't just their ability to get hot. It's how their distinct thermal properties translate directly into greater process efficiency, longer element lifespan, and a lower total cost of ownership in demanding industrial applications.

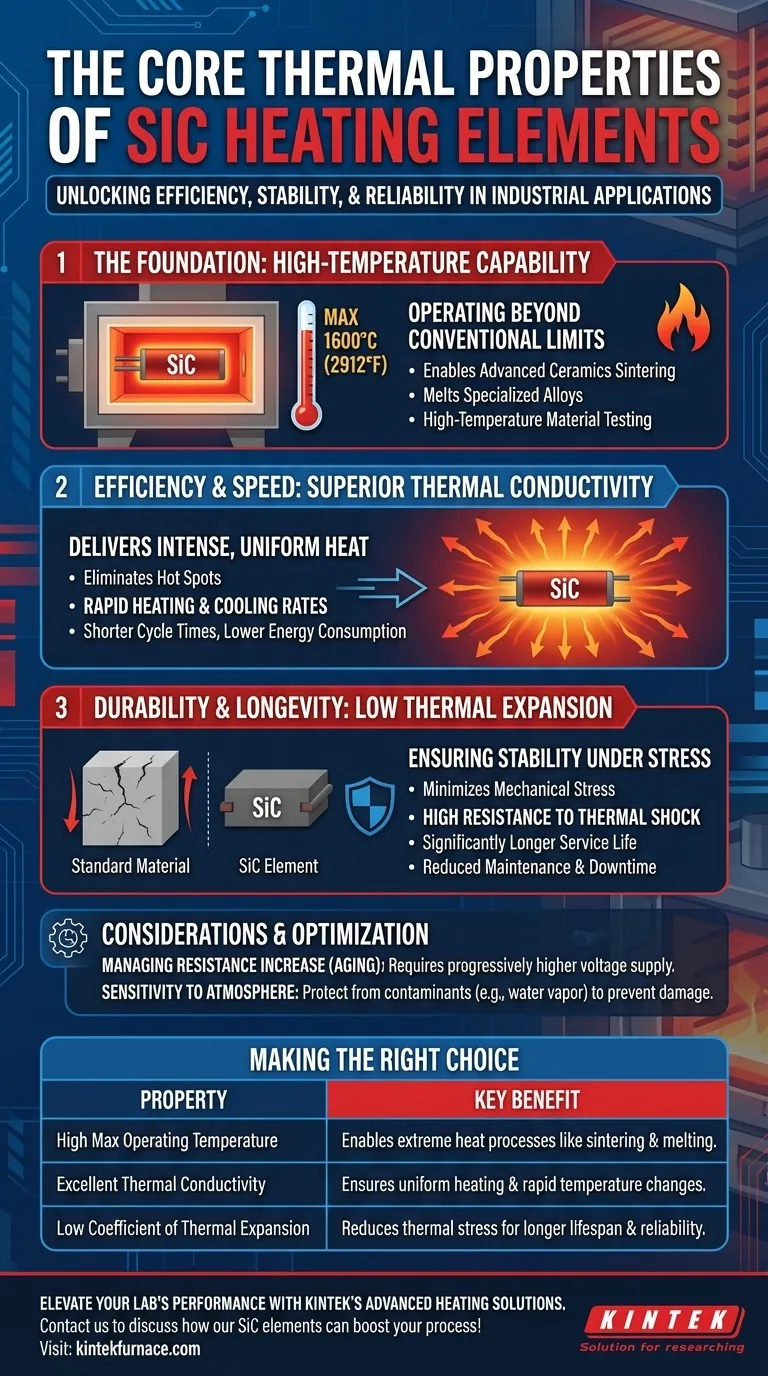

The Foundation: High-Temperature Capability

Operating Beyond Conventional Limits

Silicon Carbide elements are engineered for extreme heat. They can operate consistently at surface temperatures up to 1600°C (2912°F).

This capability unlocks industrial processes like the sintering of advanced ceramics, melting of specialized alloys, and high-temperature material testing, which are simply not feasible with conventional heating elements.

How SiC Delivers Efficient Heat

Superior Thermal Conductivity

SiC possesses excellent thermal conductivity. This means heat generated within the element is transferred quickly and efficiently to your furnace chamber and workload.

The practical benefit is highly uniform heating, eliminating the hot spots and temperature gradients that can compromise product quality and process consistency.

Rapid Heating and Cooling Rates

Because they transfer heat so effectively, SiC elements can reach target temperatures very quickly. This significantly reduces the time and energy wasted during the initial heat-up phase of a cycle.

Faster cycle times not only increase throughput but also lead to lower energy consumption per cycle, reducing both operational costs and your carbon footprint.

Ensuring Durability Under Thermal Stress

Low Coefficient of Thermal Expansion

A key property for longevity is SiC's low thermal expansion. The element expands and contracts very little, even when subjected to rapid and extreme temperature changes.

This dimensional stability minimizes the internal mechanical stress that causes fatigue, cracking, and eventual failure in other materials.

The Impact on Lifespan and Reliability

This inherent stability, combined with SiC's excellent mechanical strength, makes the elements highly resistant to breakage from thermal shock.

The result is a significantly longer service life, less frequent need for replacement, and a dramatic reduction in costly maintenance and unplanned furnace downtime.

Understanding the Trade-offs and Considerations

Managing Resistance Increase (Aging)

A known characteristic of SiC is that its electrical resistance gradually increases with use and age. This is a natural process that must be managed.

Power supply systems for SiC furnaces must be able to provide progressively higher voltage over time to maintain the required power output and process temperature.

Sensitivity to Atmosphere and Contaminants

The lifespan and performance of SiC elements can be affected by the furnace atmosphere. Certain chemicals and water vapor at high temperatures can accelerate aging or cause damage.

Proper furnace design and operational procedures are necessary to protect the elements from contaminants and ensure they perform as expected.

Making the Right Choice for Your Process

Understanding these properties is key to leveraging SiC for your specific application. It's a decision based on performance requirements and long-term value.

- If your primary focus is reaching extreme process temperatures: SiC is one of the most reliable and effective choices for applications consistently operating above 1300°C.

- If your primary focus is process efficiency and speed: The rapid heating and high conductivity of SiC directly translate to shorter cycle times and lower energy costs.

- If your primary focus is long-term reliability and minimal downtime: The low thermal expansion and robust nature of SiC lead to a longer service life, justifying the initial investment.

By evaluating these properties against your goals, you can confidently choose a heating solution that enhances process control and delivers superior long-term value.

Summary Table:

| Property | Key Benefit |

|---|---|

| High Max Operating Temperature (up to 1600°C) | Enables extreme heat processes like sintering and alloy melting |

| Excellent Thermal Conductivity | Ensures uniform heating and rapid temperature changes |

| Low Coefficient of Thermal Expansion | Reduces thermal stress for longer lifespan and reliability |

Ready to elevate your lab's performance with advanced heating solutions? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with tailored high-temperature furnace systems. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental needs. Contact us today to discuss how our SiC heating elements can boost your process efficiency, reliability, and cost-effectiveness!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What are the properties and capabilities of Silicon Carbide (SiC) as a heating element? Unlock Extreme Heat and Durability

- Why is silicon carbide resistant to chemical reactions in industrial furnaces? Unlock Durable High-Temp Solutions

- What makes silicon carbide heating elements resistant to chemical corrosion? Discover the Protective Oxide Layer

- What makes SIC heating elements superior for high-temperature applications? Unlock Efficiency and Durability

- What are the properties and applications of silicon carbide (SiC)? Unlock High-Temperature Performance