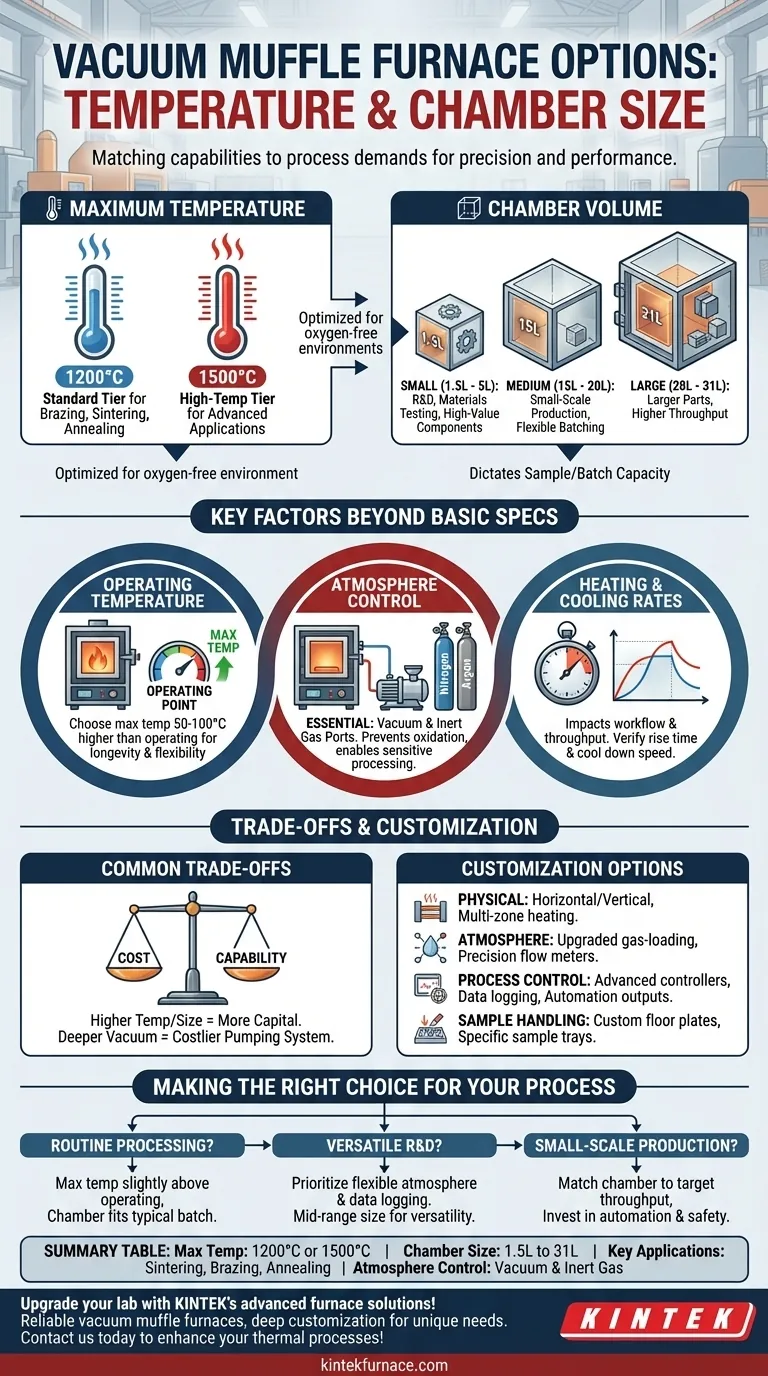

In short, vacuum muffle furnaces are typically available with maximum operating temperatures of 1200°C or 1500°C and internal chamber sizes ranging from 1.5 liters to 31 liters. These models are specifically engineered for processes requiring both high heat and a controlled atmosphere, equipped with vacuum ports and gas inlets as standard features.

Choosing the right vacuum muffle furnace is less about finding the highest temperature or largest size, and more about precisely matching the furnace's capabilities—temperature, volume, and atmosphere control—to the specific demands of your material and process.

Deconstructing the Specifications

When you see a spec sheet for a vacuum muffle furnace, the numbers for temperature and chamber size represent fundamental engineering decisions. Understanding the context of these specifications is the first step toward making an informed choice.

Maximum Temperature: 1200°C vs. 1500°C

The temperature ratings are directly tied to the heating elements and insulation used in the furnace's construction.

While standard muffle furnaces operate up to 1200°C and specialized high-temperature models can exceed 1800°C, vacuum-capable models are commonly optimized for the 1200°C and 1500°C tiers. This range covers the vast majority of applications like brazing, sintering, and annealing that also require an oxygen-free environment.

Chamber Volume: From 1.5L to 31L

The chamber size dictates your sample or batch capacity.

A smaller furnace (1.5L to 5L) is ideal for research and development, materials testing, or processing small, high-value components. Larger furnaces (15L to 31L) are better suited for small-scale production runs or processing larger parts.

Key Factors Beyond Temperature and Size

A truly effective furnace selection process looks beyond the two primary specifications. The following factors are often more critical to achieving repeatable, high-quality results.

The Role of Operating Temperature

Your target operating temperature is more important than the furnace's maximum temperature.

For equipment longevity and process flexibility, it is a best practice to select a furnace with a maximum temperature at least 50-100°C higher than your typical operating point. This prevents the heating elements from running at 100% capacity kefir a long time.

The Importance of Atmosphere Control

Vacuum muffle furnaces are defined by their ability to control the internal atmosphere. All models include ports to connect a vacuum pump and to introduce inert gases like nitrogen or argon.

This capability is essential for preventing oxidation and other unwanted chemical reactions at high temperatures, which is a non-negotiable requirement for processing sensitive metals and advanced ceramics.

Heating and Cooling Rates

The time it takes for the furnace to reach temperature (rise time) and cool down can significantly impact your workflow and throughput. This is a critical specification to verify, as it is determined by the power of the heating elements and the quality of the insulation.

Understanding the Trade-offs and Customization

Standard models serve many needs, but it's crucial to understand their limitations and the possibilities of customization.

Common Trade-offs

The primary trade-off is cost vs. capability. A furnace广告 with a higher maximum temperature or a larger chamber is a more significant capital investment.

Similarly, achieving a deeper vacuum requires a more powerful (and expensive) pumping system. You must balance the cost against the actual, validated requirements of your process.

When Standard Isn't Enough: Customization

If your process has unique demands, manufacturers offer extensive customization. These options allow you to tailor a furnace to your exact needs.

Key customization areas include:

- Physical Configuration: Horizontal or vertical loading, multi-zone heating for improved uniformity, or even tilting and rotating systems.

- Atmosphere Enhancement: Upgraded gas-loading systems with precision flow meters for more sophisticated atmosphere control.

- Process Control & Data: Advanced controllers, data logging ports (RS232C), temperature and event output terminals for automation and quality control.

- Sample Handling: Custom furnace floor plates and sample trays designed for your specific parts.

Making the Right Choice for Your Process

Your final decision should be guided by your specific application.

- If your primary focus is routine processing: Select a furnace with a maximum temperature slightly above your required operating temperature and a chamber size that comfortably fits your typical batch.

- If your primary focus is versatile R&D: Prioritize a model with flexible atmosphere control and consider data output terminals for experiment logging. A mid-range size may offer the best versatility.

- If your primary focus is small-scale production: Match the chamber size to your target throughput and invest in options for process automation and alarm outputs to ensure consistency and safety.

Ultimately, the right furnace is the one that reliably and repeatably executes your specific thermal process.

Summary Table:

| Specification | Options |

|---|---|

| Maximum Temperature | 1200°C or 1500°C |

| Chamber Size | 1.5L to 31L |

| Key Applications | Sintering, Brazing, Annealing |

| Atmosphere Control | Vacuum and inert gas (e.g., nitrogen, argon) |

Upgrade your lab with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable vacuum muffle furnaces, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs—whether for R&D, materials testing, or small-scale production. Contact us today to discuss how we can enhance your thermal processes with tailored solutions!

Visual Guide

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How does high-temperature heating facilitate the conversion of rice husks into inorganic precursors for silica extraction?

- What is the critical role of a high-temperature muffle furnace in converting biomass into Fe-N-BC?

- What is the function of a high-temperature muffle furnace in HZSM-5 preparation? Master Catalytic Activation

- How does a high-temperature muffle furnace contribute to the thermal treatment process of chalcopyrite ore?

- What is the function of a high-temperature muffle furnace in ZnO-SP preparation? Master Nanoscale Synthesis Control