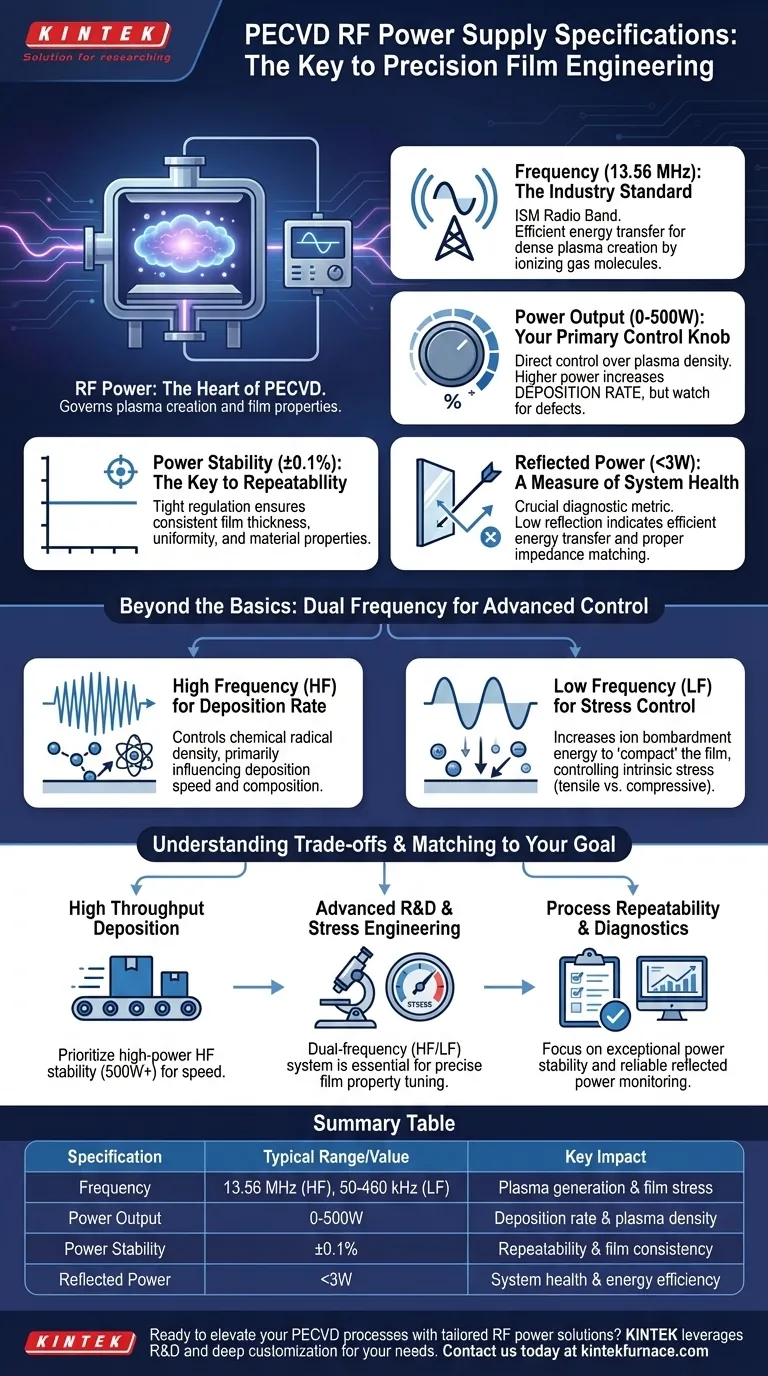

In any Plasma-Enhanced Chemical Vapor Deposition (PECVD) system, the radio frequency (RF) power supply is the heart of the process, governing the creation and characteristics of the plasma. A typical RF power supply for PECVD operates at a federally regulated frequency of 13.56 MHz with a power output ranging from 0 to 500 watts. Critically, these systems are designed for high stability (around ±0.1%) and minimal reflected power (under 3W) to ensure consistent and efficient energy transfer to the plasma.

The specifications of an RF power supply are not merely numbers; they are a direct reflection of your ability to control the plasma environment. Understanding them is the key to moving from simple film deposition to precise material engineering.

Deconstructing the Core Specifications

The numbers on a spec sheet directly translate to process capabilities. Each one serves a distinct and critical purpose in defining the plasma you can create.

Frequency (13.56 MHz): The Industry Standard

The 13.56 MHz frequency is not arbitrary. It is a designated Industrial, Scientific, and Medical (ISM) radio band, allowing high-power operation without interfering with commercial communication services.

This high frequency is highly effective at transferring energy to electrons, which in turn collide with and ionize the precursor gas molecules, efficiently creating a dense plasma.

Power Output (0-500W): Your Primary Control Knob

Power output, typically adjustable from 0 up to 300W or 500W, is the most direct control you have over the plasma.

Increasing the power generally increases the plasma density (the number of ions and radicals). This directly influences the deposition rate of your film. More power means a faster deposition, but it is not without consequences.

Power Stability (±0.1%): The Key to Repeatability

Power stability dictates how much the output power wavers during a process. A specification of ±0.1% is extremely tight for a reason.

Even small fluctuations in power can alter plasma density and ion energy, leading to variations in film thickness, uniformity, and material properties. High stability is essential for repeatable, production-worthy results.

Reflected Power (<3W): A Measure of System Health

Reflected power is the energy that the plasma and chamber fail to absorb, bouncing back to the power supply. It is a crucial diagnostic metric.

Low reflected power indicates that the system's impedance is properly matched, and energy is being transferred efficiently. High reflected power signals a problem, such as an unstable plasma, issues with the chamber, or a failing impedance matching network.

Beyond the Basics: The Role of Frequency in Film Control

Advanced PECVD systems often employ more than just a single high-frequency supply. The introduction of a second, lower frequency unlocks a new dimension of process control, particularly for film stress.

High Frequency (HF) for Deposition Rate

As discussed, the 13.56 MHz HF supply is excellent at generating a high density of chemical radicals. These are the primary building blocks for the film.

Therefore, the HF power primarily controls the deposition rate and has a strong influence on the film's chemical composition.

Low Frequency (LF) for Stress Control

Many systems also include a Low Frequency (LF) generator, operating in the 50-460 kHz range. This LF power has a much different effect on the plasma.

LF power significantly increases the energy of ions bombarding the substrate. This ion bombardment can be used to physically "compact" the growing film, which is the primary mechanism for controlling intrinsic film stress. By blending HF and LF power, you can tune a film from tensile to compressive stress.

Understanding the Trade-offs

Selecting or operating a system requires balancing competing factors. More power or speed is not always the superior choice.

High Power vs. Film Quality

While higher power increases deposition rate, it can also lead to more defects. Excessive ion bombardment can damage the substrate or the growing film, and very high plasma density can lead to unwanted gas-phase particle formation (dust).

Deposition Rate vs. Film Stress

Pushing for a fast deposition rate using only HF power often results in films with high intrinsic stress, which can cause cracking or delamination. Controlling this stress with LF power often requires reducing the overall deposition rate.

Single vs. Dual Frequency Systems

A single-frequency (HF) system is simpler, more reliable, and less expensive. It is perfectly adequate for applications where film stress is not a primary concern.

A dual-frequency (HF/LF) system provides a far greater process window, enabling precise control over stress. This capability comes at the cost of increased system complexity and expense.

Matching the Power Supply to Your Goal

The ideal specifications are directly tied to your intended application. Evaluate your needs based on the final properties you want to achieve in your film.

- If your primary focus is high-throughput deposition: A robust, high-power (500W+) HF supply with excellent stability is your most critical component.

- If your primary focus is advanced R&D and stress engineering: A dual-frequency system with both HF and LF capabilities is non-negotiable for controlling film properties.

- If your primary focus is process repeatability and diagnostics: Pay closest attention to power stability and ensure the system provides reliable reflected power monitoring.

Ultimately, understanding these specifications transforms the RF power supply from a simple component into your most precise tool for engineering film performance.

Summary Table:

| Specification | Typical Range/Value | Key Impact |

|---|---|---|

| Frequency | 13.56 MHz (HF), 50-460 kHz (LF) | Controls plasma generation and film stress |

| Power Output | 0-500W | Influences deposition rate and plasma density |

| Power Stability | ±0.1% | Ensures repeatability and consistent film properties |

| Reflected Power | <3W | Indicates system health and energy efficiency |

Ready to elevate your PECVD processes with tailored RF power solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace systems, including CVD/PECVD Systems. Our deep customization capabilities ensure precise alignment with your unique experimental needs, whether for high-throughput deposition, stress engineering, or reliable R&D. Contact us today to discuss how our expertise can optimize your film deposition and drive your innovations forward!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

People Also Ask

- What is PECVD and how does it differ from traditional CVD? Unlock Low-Temperature Thin Film Deposition

- How does the PECVD process work? Enable Low-Temperature, High-Quality Thin Film Deposition

- What is the second benefit of deposition within a discharge in PECVD? Enhance Film Quality with Ion Bombardment

- What are the advantages of plasma enhanced CVD? Achieve Low-Temperature, High-Quality Thin Film Deposition

- How does plasma enhanced CVD work? Achieve Low-Temperature, High-Quality Thin Film Deposition