In essence, the primary advantages of Chemical Vapor Deposition (CVD) are its exceptional control over film properties and its ability to uniformly coat complex surfaces. Because the process uses chemical precursors in a gas phase, it can create highly pure, dense, and consistent thin films with precisely tailored thickness and composition. This unique capability to conform to intricate, non-line-of-sight geometries makes CVD an indispensable process in demanding fields like semiconductor manufacturing, aerospace engineering, and biomedical devices.

While many processes can deposit a layer of material, CVD's core strength is its ability to grow a new surface from the ground up, molecule by molecule. This gas-phase reaction allows it to conform perfectly to any geometry, creating engineered films of unparalleled purity and uniformity that are often impossible to achieve with other methods.

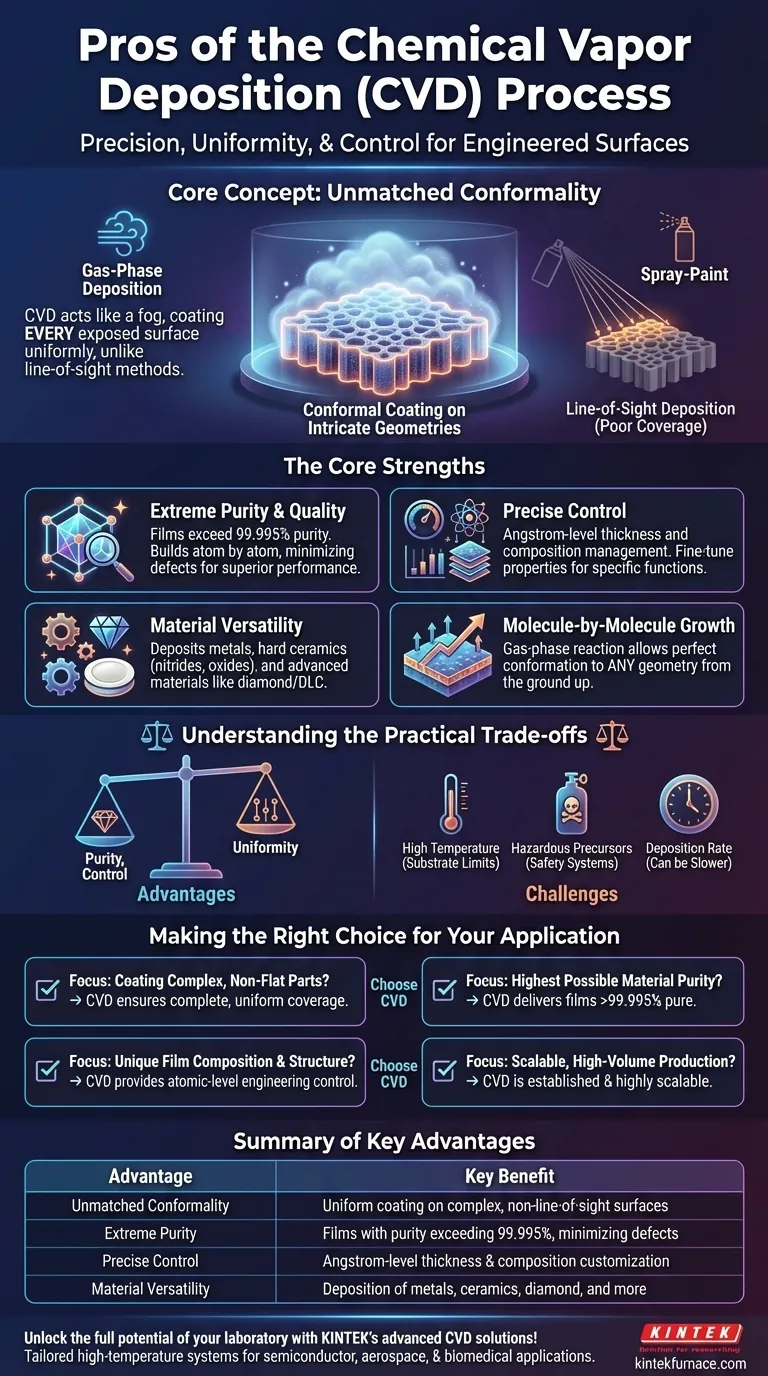

The Core Strengths of the CVD Process

To understand why CVD is chosen for critical applications, we must look beyond a simple list of benefits and examine how its fundamental mechanism delivers tangible advantages.

Unmatched Conformality and Uniformity

The defining feature of CVD is its use of gaseous reactants. Unlike line-of-sight deposition methods (like Physical Vapor Deposition or PVD) that act like a spray-paint can, CVD works more like a fog that fills every corner of a chamber.

This allows the chemical reaction to occur uniformly on all exposed surfaces, regardless of their orientation or complexity. The result is a highly conformal coating that perfectly replicates intricate topographies, trenches, and even the internal surfaces of porous materials.

Extreme Purity and Material Quality

CVD is capable of producing films with exceptional purity, often exceeding 99.995%. This is because the precursor gases can be refined to very high standards before they are introduced into the reaction chamber.

The process itself is also inherently clean, effectively building the desired film atom by atom while byproducts are exhausted as gas. This minimizes impurities and defects, leading to superior electrical, optical, and mechanical performance of the final film.

Precise Control Over Film Properties

The CVD process offers an incredible degree of control. By carefully managing variables like gas flow rates, temperature, and pressure, operators can precisely dictate the final properties of the film.

This includes customizing film thickness with angstrom-level precision, controlling the chemical composition by mixing different precursor gases, and even influencing the film's crystalline structure. This makes it possible to engineer a surface for a specific function.

Unparalleled Material Versatility

CVD is not limited to a single class of materials. The process is incredibly versatile and can be adapted to deposit a vast range of substances.

This includes metals and metal alloys, hard ceramics like nitrides and oxides, and even advanced materials like diamond and diamond-like carbon (DLC). This flexibility allows it to be applied to a wide array of industrial and research challenges.

Understanding the Practical Trade-offs

No process is without its challenges. While powerful, the advantages of CVD come with practical considerations that are critical for making an informed decision.

Process Temperature

Many, though not all, CVD processes require high temperatures to drive the necessary chemical reactions. This can be a significant limitation when working with temperature-sensitive substrates, such as certain plastics or pre-processed semiconductor wafers. While low-temperature CVD variants exist, they often involve their own set of compromises.

Precursor Gas Handling

The precursor chemicals used in CVD are often volatile, toxic, corrosive, or pyrophoric (igniting on contact with air). This necessitates sophisticated and expensive gas handling and safety systems, as well as rigorous operational protocols to protect personnel and equipment.

Deposition Rate

While one reference notes the process can be "quick," CVD can sometimes have a lower deposition rate compared to certain PVD techniques, especially for very thick coatings. For applications where sheer volume and speed are the primary drivers and film quality is secondary, CVD may not be the most cost-effective choice.

Making the Right Choice for Your Application

Selecting a deposition method depends entirely on your project's most critical requirement.

- If your primary focus is coating complex, non-flat parts: CVD is likely the superior choice due to its gas-phase nature ensuring complete and uniform coverage where line-of-sight methods would fail.

- If your primary focus is achieving the highest possible material purity: CVD's ability to produce films exceeding 99.995% purity for critical electronic or optical performance is a decisive advantage.

- If your primary focus is developing a unique film with a specific composition or structure: CVD provides the fine-tuned control necessary to engineer materials at the atomic level, layer by layer.

- If your primary focus is scaling from research to high-volume industrial production: CVD processes are well-established, controllable, and highly scalable for manufacturing environments.

Ultimately, choosing CVD is a decision to engineer a surface with precision, rather than simply to cover one.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Unmatched Conformality | Uniform coating on complex, non-line-of-sight surfaces |

| Extreme Purity | Films with purity exceeding 99.995%, minimizing defects |

| Precise Control | Angstrom-level thickness and composition customization |

| Material Versatility | Deposition of metals, ceramics, diamond, and more |

Unlock the full potential of your laboratory with KINTEK's advanced CVD solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with high-temperature furnace systems like CVD/PECVD, tailored to your unique experimental needs. Our deep customization capability ensures precise performance for semiconductor, aerospace, and biomedical applications. Contact us today to discuss how we can enhance your research and production processes!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

People Also Ask

- How does plasma enhanced CVD work? Achieve Low-Temperature, High-Quality Thin Film Deposition

- How is silicon dioxide (SiO2) used in PECVD applications? Key Roles in Microfabrication

- What are the main components of a PECVD system? Unlock Low-Temperature Thin Film Deposition

- What is PECVD and how does it differ from traditional CVD? Unlock Low-Temperature Thin Film Deposition

- What is plasma enhanced chemical vapor deposition application? Enable High-Performance Thin Films at Lower Temperatures