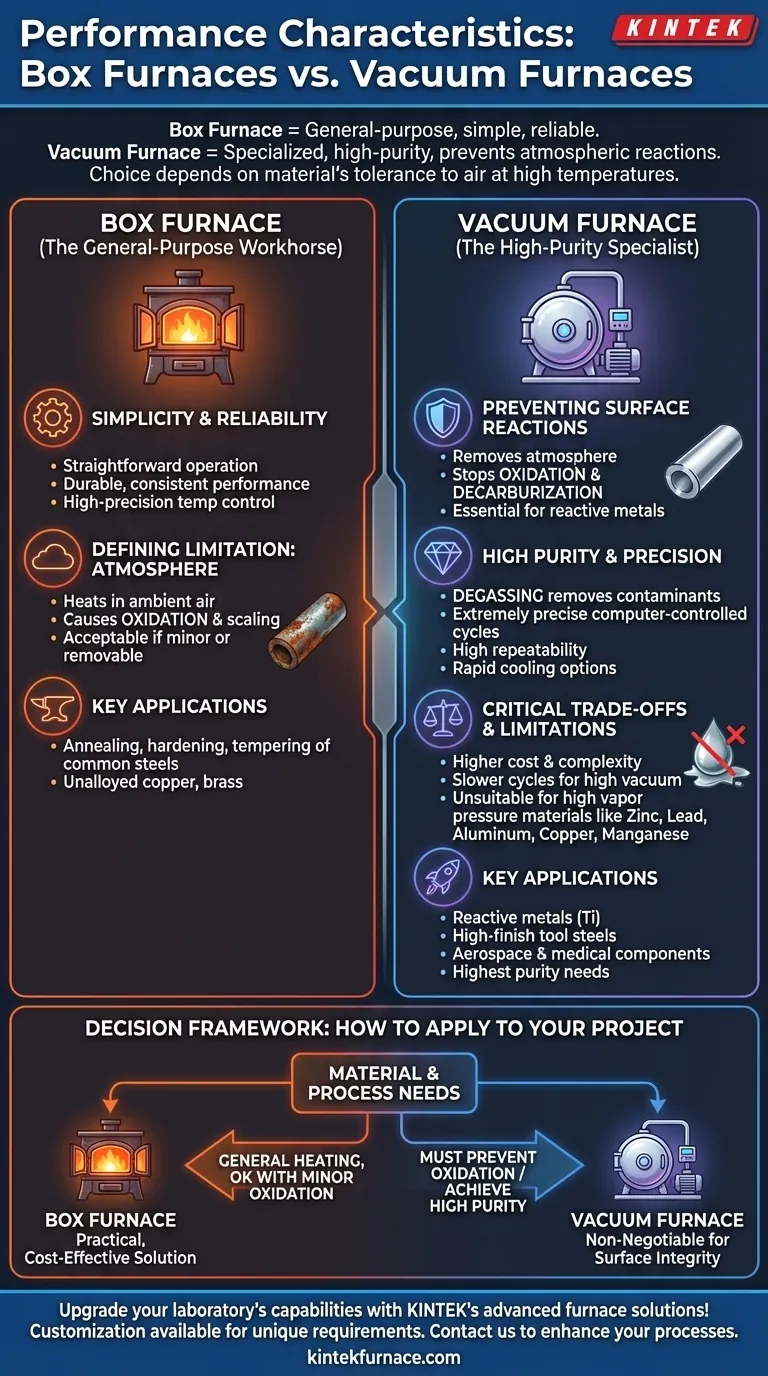

In essence, a box furnace is a general-purpose tool valued for its simplicity and reliability in standard heat-treating applications, while a vacuum furnace is a specialized instrument designed for high-purity processes where preventing atmospheric reactions is critical. The choice between them depends entirely on whether your material's integrity can tolerate exposure to air at high temperatures.

Your decision framework is straightforward: if you must prevent oxidation, decarburization, or other surface reactions, you need a vacuum furnace. For most other industrial heating tasks, the simplicity and ease of use of a box furnace make it the more practical and economical choice.

The Box Furnace: The General-Purpose Workhorse

A box furnace, also known as a muffle furnace, is the standard for many heat treatment processes. Its performance is defined by reliability and ease of use for applications where atmospheric control is not the primary concern.

Simplicity and Reliability

The primary advantage of a box furnace is its straightforward operation and maintenance. These furnaces are designed for durability and consistent performance in typical industrial environments.

They provide high-precision temperature control and maintain a constant, uniform temperature within the chamber, making them suitable for a wide range of applications like annealing, hardening, and tempering.

The Defining Limitation: Atmosphere

A box furnace heats material in the presence of the ambient atmosphere (air). This means oxygen is present, which will cause oxidation and scaling on the surface of most metals at high temperatures.

This is not a defect but a fundamental characteristic. If minor surface oxidation is acceptable or can be easily removed through a secondary process like sandblasting or pickling, a box furnace is often sufficient.

The Vacuum Furnace: The High-Purity Specialist

A vacuum furnace performs heat treatment in a chamber where the atmosphere has been removed. This single difference creates a completely distinct set of performance characteristics geared toward material purity and surface integrity.

Preventing Surface Reactions

The core function of a vacuum furnace is to prevent unwanted chemical reactions. By removing oxygen and other gases, it stops oxidation and decarburization from occurring.

This is essential for processing reactive metals like titanium, high-finish tool steels, and materials for aerospace or medical applications where surface properties cannot be compromised.

Achieving High Purity

A vacuum environment actively pulls contaminants and by-products out of the material as it is heated, a process known as degassing. This results in a final product with higher purity and improved mechanical properties.

Precision, Control, and Speed

Vacuum furnaces offer extremely precise, computer-controlled heating and cooling cycles. This ensures process repeatability, which is critical for meeting stringent quality standards.

Key performance metrics include:

- Temperature Uniformity: Precise control within heated zones up to 3,000°C.

- Vacuum Level: Can range from low vacuum to ultra-high vacuum (as low as 1x10⁻¹¹ torr).

- Rapid Cooling: Many are equipped with gas quenching systems for fast, controlled cooling.

Cycle Time Considerations

Throughput is directly tied to the required vacuum level. Low-vacuum furnaces have faster pump-down and overall cycle times. High-vacuum systems require significantly more time to remove trace gases, resulting in slower cycles.

Understanding the Critical Trade-offs

Neither furnace is universally superior; they are engineered for different tasks. Understanding their limitations is crucial for making an informed decision.

Material Compatibility in a Vacuum

Vacuum furnaces are unsuitable for heating materials with a high saturated vapor pressure.

Metals like zinc, lead, aluminum, copper, and manganese can evaporate or "boil" under vacuum at high temperatures. This not only damages the part but can also contaminate the inside of the furnace.

Heating Uniformity Challenges

While precise, achieving perfectly uniform heating in a vacuum can be challenging, especially for large or complex-shaped workpieces. Heat transfer in a vacuum relies primarily on radiation, which can lead to hot and cold spots without specialized tooling and carefully designed processes.

Throughput vs. Purity

The relationship between cycle time and vacuum level presents a direct trade-off. Achieving the highest purity with an ultra-high vacuum comes at the cost of lower throughput. For high-volume production, this can be a significant bottleneck.

Complexity and Cost

Vacuum furnaces are inherently more complex systems. They require vacuum pumps, sophisticated control systems, and more rigorous maintenance, making them a significantly higher capital and operational investment compared to box furnaces.

How to Apply This to Your Project

Your choice should be dictated by your material, your process requirements, and your production goals.

- If your primary focus is general annealing, tempering, or stress-relieving of common steels: A box furnace is the most practical and cost-effective solution.

- If you are processing reactive metals, medical implants, or aerospace components: The atmospheric control of a vacuum furnace is non-negotiable to ensure surface integrity.

- If your goal is to degas a material or achieve the highest possible purity: You must use a vacuum furnace.

- If you are heating materials like unalloyed copper, brass, or certain aluminum alloys: A box furnace or a controlled-atmosphere furnace (using inert gas) is required, as a vacuum furnace can damage the material.

Ultimately, your decision rests on a clear understanding of your material's interaction with atmosphere at temperature.

Summary Table:

| Characteristic | Box Furnace | Vacuum Furnace |

|---|---|---|

| Atmosphere | Ambient air (oxygen present) | Vacuum (no oxygen) |

| Key Applications | Annealing, hardening, tempering of common steels | Processing reactive metals, medical implants, aerospace components |

| Temperature Control | High precision, uniform heating | Extremely precise, computer-controlled cycles |

| Cost and Complexity | Lower cost, simpler operation | Higher cost, more complex with vacuum systems |

| Limitations | Causes oxidation and scaling | Unsuitable for high vapor pressure materials like zinc or copper |

Upgrade your laboratory's capabilities with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization to meet unique experimental requirements. Whether you need the reliability of a box furnace or the purity of a vacuum furnace, we deliver precise, efficient solutions. Contact us today to discuss how we can enhance your heat treatment processes and achieve superior results!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- How does a vacuum heat treatment furnace influence Ti-6Al-4V microstructure? Optimize Ductility and Fatigue Resistance

- What are the functions of a high-vacuum furnace for CoReCr alloys? Achieve Microstructural Precision and Phase Stability

- What is the vacuum heat treatment process? Achieve Superior Surface Quality and Material Performance

- What are the general operational features of a vacuum furnace? Achieve Superior Material Purity & Precision

- What role does a high-temperature vacuum heat treatment furnace play in LP-DED? Optimize Alloy Integrity Today