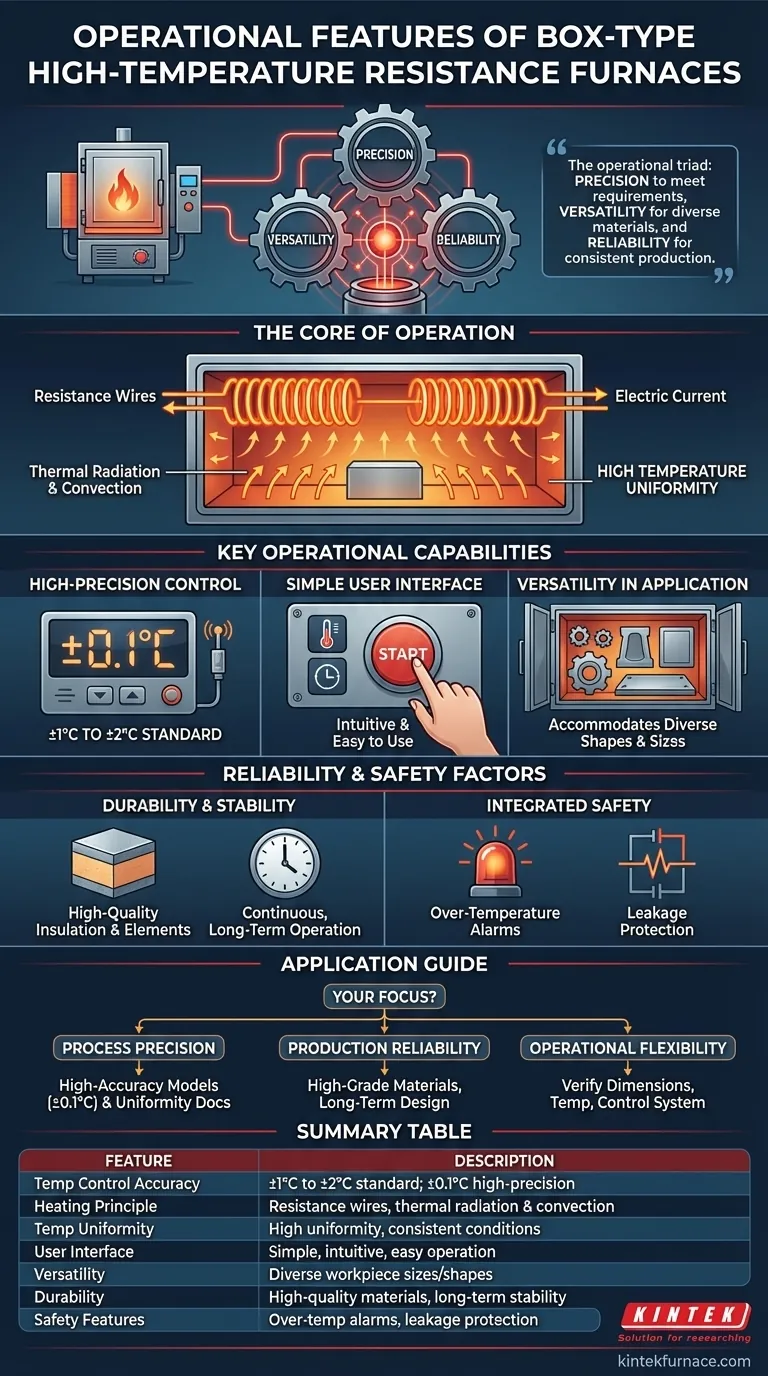

At their core, the operational features of box-type high-temperature resistance furnaces are defined by a synthesis of user-friendly control, high-precision temperature management, and robust, integrated safety systems. These elements work together to create a reliable and versatile tool for a wide range of thermal processing applications.

The true value of these furnaces lies not just in their ability to reach high temperatures, but in their operational triad: the precision to meet strict process requirements, the versatility to handle diverse materials, and the reliability to ensure consistent production with minimal downtime.

The Core of Operation: How They Work

To understand their features, it is essential to first understand their fundamental design. This simplicity is the foundation of their operational flexibility.

The Heating Principle

These furnaces are universal heating equipment that employ resistance wires as their primary heating elements. An electric current passes through these elements, generating intense heat.

This heat is then transferred to the workpiece inside the chamber primarily through thermal radiation and convection, ensuring the entire space is heated.

High Temperature Uniformity

A core advantage derived from this design is high temperature uniformity. The placement and quality of the heating elements ensure that heat is distributed evenly throughout the furnace chamber.

This uniformity is critical for processes where every part of the workpiece must experience the exact same thermal conditions for a consistent outcome.

Key Operational Capabilities

The operational capabilities are what make these furnaces indispensable in laboratories and industrial settings. They are designed for both performance and ease of use.

High-Precision Temperature Control

Modern box-type furnaces are equipped with high-precision temperature control systems and sensitive sensors. This allows for an exceptional level of accuracy.

Standard models typically achieve a temperature control accuracy of ±1°C to ±2°C. For highly sensitive applications, such as semiconductor material annealing, high-precision models can maintain an accuracy of ±0.1°C.

Simple, User-Friendly Interface

Despite their advanced capabilities, these furnaces are designed for straightforward operation. The user interface is typically intuitive, allowing for simple starting, stopping, and temperature setting after minimal training.

Versatility in Application

The design of the furnace interior—typically spacious and regularly shaped—provides significant versatility. They can accommodate a wide variety of workpiece sizes and shapes, from small, delicate precision parts to large industrial molds.

Understanding the Reliability and Safety Factors

Reliability is not just a feature but a requirement for production environments. These furnaces integrate components and systems designed for longevity and safety.

Durability and Stability

The long-term performance is ensured by using high-quality heating elements and insulation materials. These components are selected for their high temperature and oxidation resistance.

This robust construction allows for continuous, long-term operation with high stability, reducing production downtime and maintenance needs.

Integrated Safety Protocols

Operator safety and equipment protection are paramount. These furnaces include critical safety features to prevent accidents and damage.

Key protections include over-temperature alarms, which automatically cut power if the temperature exceeds a set limit, and leakage protection circuits to prevent electrical hazards. These systems ensure both the operator and the equipment remain safe.

How to Apply This to Your Project

Choosing the right furnace requires matching its operational characteristics to your specific technical goals.

- If your primary focus is process precision: Seek out models that explicitly specify high-accuracy controllers (e.g., ±0.1°C) and provide documentation on their temperature uniformity.

- If your primary focus is production reliability: Prioritize furnaces built with high-grade heating elements and superior insulation materials designed for continuous, long-term operation.

- If your primary focus is operational flexibility: Verify that the furnace's internal dimensions, maximum temperature, and control system can handle the full spectrum of your intended applications.

Ultimately, understanding these operational features empowers you to select a furnace that functions not just as a tool, but as a precise and reliable part of your process.

Summary Table:

| Feature | Description |

|---|---|

| Temperature Control Accuracy | ±1°C to ±2°C standard; ±0.1°C for high-precision models |

| Heating Principle | Resistance wires with thermal radiation and convection |

| Temperature Uniformity | High uniformity for consistent thermal conditions |

| User Interface | Simple and intuitive for easy operation |

| Versatility | Handles diverse workpiece sizes and shapes |

| Durability | High-quality elements and insulation for long-term stability |

| Safety Features | Over-temperature alarms and leakage protection circuits |

Upgrade your thermal processing with KINTEK's advanced high-temperature furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure precise alignment with your unique experimental needs, enhancing efficiency and reliability. Contact us today to discuss how our furnaces can optimize your operations!

Visual Guide

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- Why is a box muffle furnace used for the 800°C annealing of titanium LMD samples? Optimize Your Material Performance

- How is a laboratory muffle furnace utilized during the debinding stage of HAp green bodies? Precision Thermal Control

- How is a muffle furnace utilized for AlN crystal post-processing? Optimize Surface Purity via Staged Oxidation

- What is the function of laboratory high-temperature box furnaces in T6 aluminum treatment? Key to Material Strength

- What role does a high-temperature box resistance furnace play in sintering? Mastering Electrolyte Tube Densification