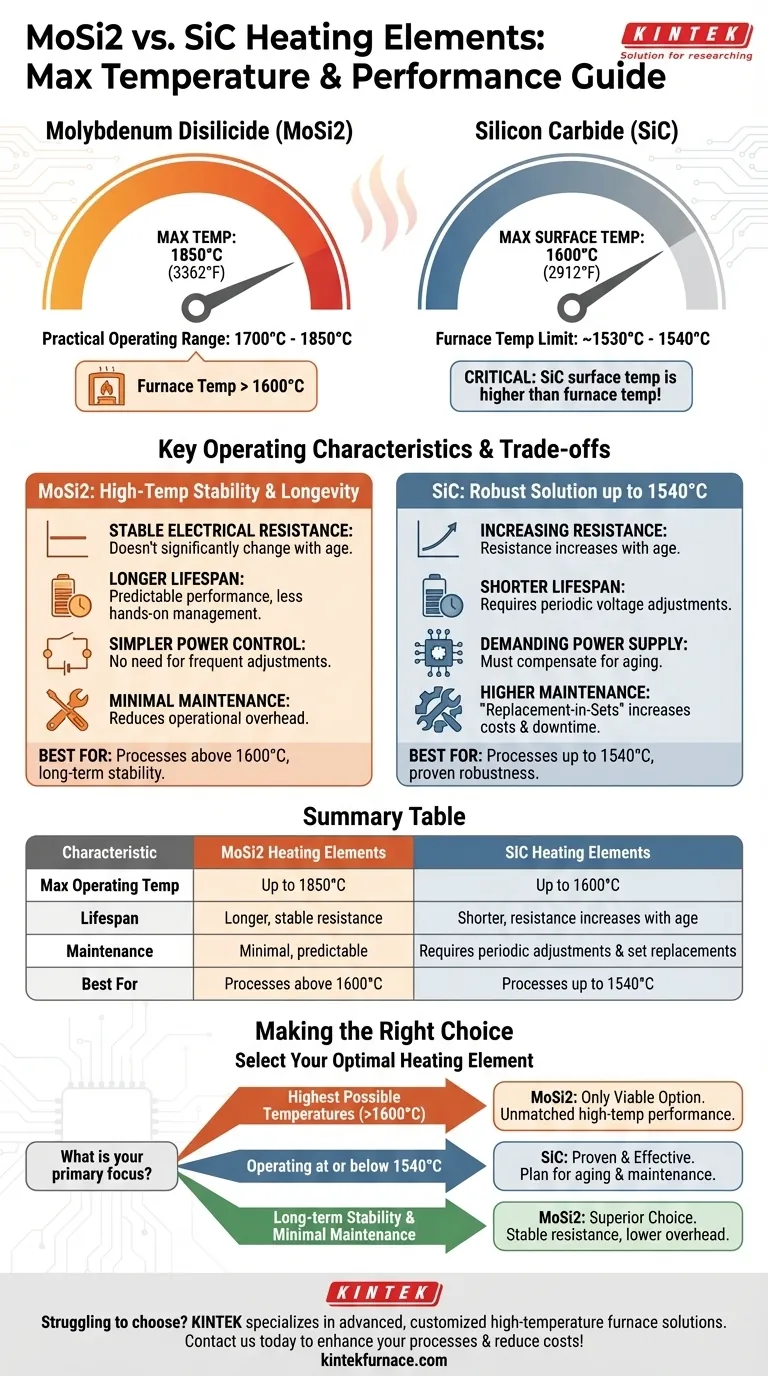

For high-temperature industrial processes, Molybdenum Disilicide (MoSi2) heating elements can achieve significantly higher operating temperatures than Silicon Carbide (SiC) elements. The maximum practical temperature for MoSi2 elements is typically around 1850°C (3362°F), while SiC elements are generally limited to a maximum surface temperature of 1600°C (2912°F).

The choice between MoSi2 and SiC is not simply about the maximum temperature. It is a critical engineering decision that must account for the required furnace atmosphere, the element's aging characteristics, and the long-term cost of maintenance and replacement.

A Closer Look at Molybdenum Disilicide (MoSi2)

Maximum vs. Practical Operating Temperature

While MoSi2 has a material capability of reaching up to 1900°C, its reliable, long-term operating temperature is more commonly rated between 1700°C and 1850°C.

Specific grades of MoSi2 elements are designed for different temperature ranges. For example, it is common to see models rated for a continuous working temperature of 1700°C, with higher-grade models capable of sustaining 1800°C.

Key Operating Characteristics

MoSi2 elements are valued for their ability to maintain stable performance at extreme temperatures. Unlike SiC, their electrical resistance does not significantly change with age, which contributes to a longer and more predictable lifespan.

This stability simplifies power control and reduces the need for frequent furnace adjustments or complex replacement schedules.

Understanding Silicon Carbide (SiC)

The 1600°C Ceiling

SiC heating elements are a robust and widely used solution for processes requiring temperatures up to 1600°C. They are a workhorse in many industries but cannot match the extreme temperature range of MoSi2.

Element Temperature vs. Furnace Temperature

A critical factor to consider is the thermal gradient between the element and the furnace chamber. An SiC element operating at its maximum surface temperature of 1600°C will typically result in a maximum furnace chamber temperature of around 1530°C to 1540°C. This distinction is vital for process design.

The Challenge of Aging and Resistance

The primary operational drawback of SiC is that its electrical resistance increases as it ages. This change requires periodic voltage adjustments to maintain the desired power output.

Furthermore, when one element in a set fails, all elements in that circuit group must be replaced together to maintain a balanced electrical load. This "replacement-in-sets" requirement can increase maintenance costs and downtime.

Understanding the Trade-offs

Temperature Capability

For any process requiring a furnace temperature above approximately 1550°C, MoSi2 is the clear choice. It is the only one of the two materials capable of reliably reaching the 1600°C to 1800°C range.

Lifespan and Maintenance

MoSi2 elements generally offer a longer operational lifespan and require less hands-on management due to their stable resistance over time.

SiC elements have a shorter lifespan and a more demanding maintenance schedule. The need to replace elements in matched sets must be factored into the total cost of ownership.

Circuit and Power Considerations

The aging characteristics of SiC necessitate a power supply system that can compensate for the increasing resistance over the element's life. MoSi2 circuits are generally simpler in this regard.

Making the Right Choice for Your Goal

Selecting the correct heating element is fundamental to furnace design and operational efficiency. Base your decision on the specific, long-term requirements of your application.

- If your primary focus is reaching the highest possible temperatures (above 1600°C): MoSi2 is your only viable option, offering performance that SiC cannot match.

- If your primary focus is operating at or below 1540°C: SiC is a proven and effective solution, but you must plan for its specific aging and maintenance requirements.

- If your primary focus is long-term stability and minimal maintenance: MoSi2 is the superior choice due to its stable resistance, which leads to a longer lifespan and lower operational overhead.

By understanding these core differences, you can select the heating element that provides the optimal balance of performance, longevity, and efficiency for your high-temperature process.

Summary Table:

| Characteristic | MoSi2 Heating Elements | SiC Heating Elements |

|---|---|---|

| Max Operating Temp | Up to 1850°C | Up to 1600°C |

| Lifespan | Longer, stable resistance | Shorter, resistance increases with age |

| Maintenance | Minimal, predictable | Requires periodic adjustments and set replacements |

| Best For | Processes above 1600°C | Processes up to 1540°C |

Struggling to choose the right heating element for your high-temperature furnace? KINTEK specializes in advanced solutions for diverse laboratories, offering Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With exceptional R&D and in-house manufacturing, we provide deep customization to precisely meet your unique experimental needs—ensuring optimal performance, longevity, and efficiency. Contact us today to discuss how our tailored high-temperature furnace solutions can enhance your processes and reduce maintenance costs!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What are the operational characteristics of SiC heating elements? Maximize High-Temp Performance and Efficiency

- What types of heating elements are commonly used in drop tube furnaces? Find the Right Element for Your Temperature Needs

- What parameters does the IEC standard specify for heating elements? Ensure Safety and Performance

- What is the difference between SiC and MoSi2? Choose the Right High-Temp Heating Element

- What is the temperature range for silicon carbide heating elements? Unlock High-Temp Performance from 600°C to 1625°C