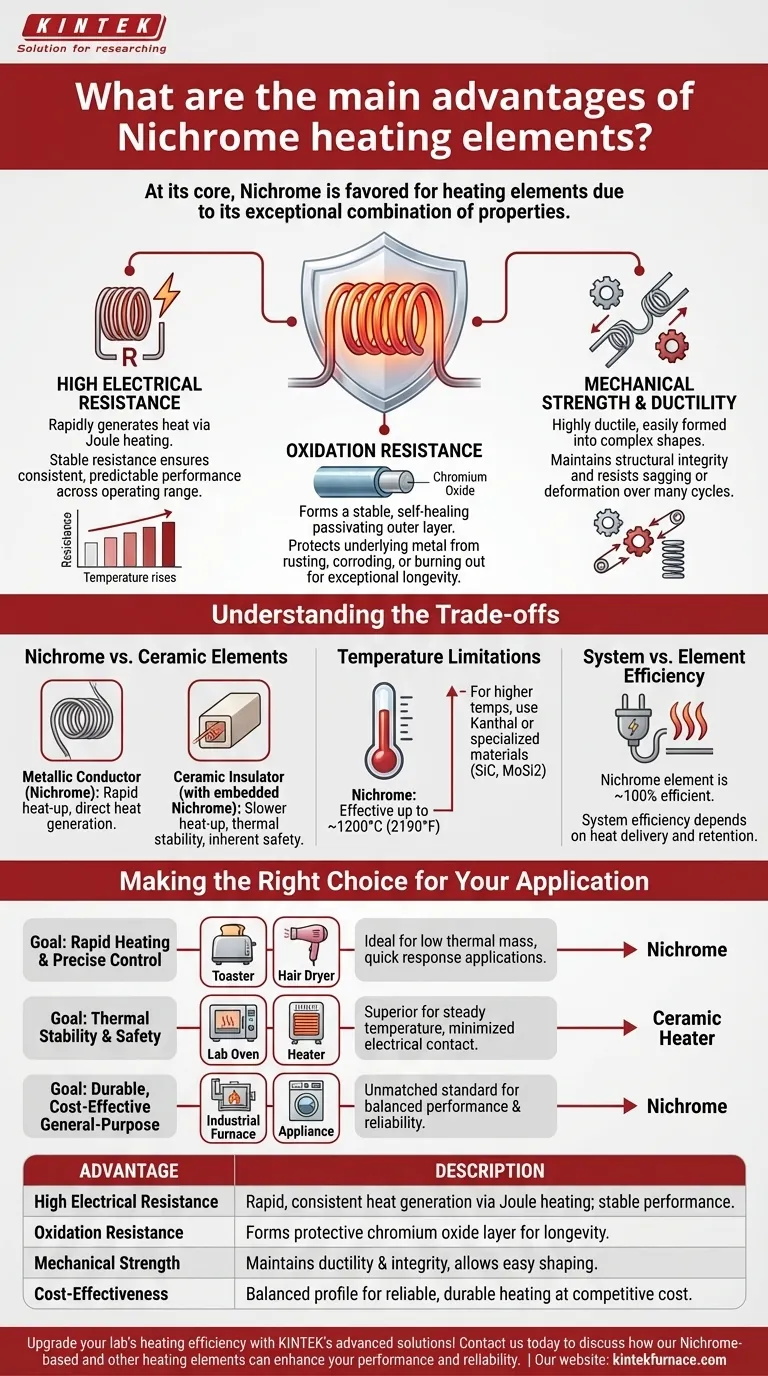

At its core, Nichrome is favored for heating elements due to its exceptional combination of high electrical resistance, outstanding resistance to oxidation at high temperatures, and mechanical stability. This unique blend of properties allows it to reliably and consistently convert electricity into heat over thousands of hours of operation, making it the standard for a vast range of applications from household appliances to industrial furnaces.

The true advantage of Nichrome is not just one single attribute, but its balanced profile. It provides predictable, durable, and controllable heat in a form factor that is both strong and easy to manufacture, creating a powerful and cost-effective solution.

The Core Properties of Nichrome

To understand why Nichrome is so effective, we must look at its fundamental material characteristics when subjected to high heat and electrical current.

High Electrical Resistance

Nichrome is an alloy, primarily of nickel and chromium, specifically designed to have a high electrical resistance. When current flows through it, this resistance causes the element to heat up rapidly—a phenomenon known as Joule heating.

Crucially, this resistance remains relatively stable across its operating temperature range. This ensures that the heat output is consistent and predictable, a vital characteristic for any controlled heating process.

Formation of a Protective Oxide Layer

The defining feature of Nichrome is its performance at high temperatures. When heated, the chromium in the alloy forms a passivating outer layer of chromium oxide.

This thin, adherent layer is extremely stable and protects the underlying metal from further oxidation. It is this self-healing "skin" that prevents the element from rusting, corroding, or burning out quickly, giving it exceptional longevity.

Ductility and Mechanical Strength

Unlike some other high-temperature materials, Nichrome is highly ductile. This means it can be easily drawn into wire and formed into complex shapes like coils and ribbons without breaking.

It also maintains good mechanical strength at high temperatures, resisting sagging or deforming over many heating and cooling cycles. This structural integrity is critical for ensuring the element remains in its intended position and does not cause a short circuit.

Understanding the Trade-offs

While Nichrome is an excellent general-purpose choice, it is not the universal solution for all heating applications. Objective analysis requires understanding its limitations and how it compares to alternatives.

Nichrome vs. Ceramic Elements

A common point of confusion is the difference between Nichrome and ceramic heaters. Nichrome is a metallic conductor that generates heat itself; it requires separate electrical insulation.

Ceramic heating elements, by contrast, are electrical insulators that house an embedded heating coil (often Nichrome). The ceramic body heats up and radiates that heat. While this provides inherent electrical safety and excellent thermal stability, it results in a slower heat-up and cool-down time compared to an exposed Nichrome element.

Temperature Limitations

Nichrome is effective up to approximately 1200°C (2190°F). For applications requiring even higher temperatures, other materials are necessary.

Alloys like Kanthal (FeCrAl) can operate at higher temperatures but are more brittle. For extreme industrial processes, materials like molybdenum disilicide or silicon carbide are used, though they come with significant cost and complexity trade-offs.

System Efficiency vs. Element Efficiency

The conversion of electricity to heat in any resistive element, including Nichrome, is nearly 100% efficient.

The difference in "energy efficiency" between systems comes down to how well that generated heat is delivered to the target and retained. A system with a slow-cooling ceramic element may be perceived as more efficient in an oven that needs to hold a stable temperature, while a fast-heating, low-mass Nichrome coil is far more efficient for applications requiring rapid, on-demand heat.

Making the Right Choice for Your Application

Selecting the correct heating element requires matching the material's properties to the primary goal of your design.

- If your primary focus is rapid heating and precise control: Nichrome's low thermal mass and quick response time make it the ideal choice for applications like toasters, hair dryers, and heat guns.

- If your primary focus is thermal stability and inherent safety: A ceramic heater is superior where maintaining a steady temperature is critical and the risk of electrical contact must be minimized.

- If your primary focus is durable, cost-effective general-purpose heating: Nichrome remains the unmatched standard for a vast majority of applications due to its balanced performance, reliability, and manufacturability.

Ultimately, choosing the right material begins with a clear understanding of the specific demands of your application.

Summary Table:

| Advantage | Description |

|---|---|

| High Electrical Resistance | Enables rapid, consistent heat generation via Joule heating with stable performance across temperatures. |

| Oxidation Resistance | Forms a protective chromium oxide layer for longevity and corrosion prevention at high temperatures. |

| Mechanical Strength | Maintains ductility and structural integrity, allowing easy shaping and resistance to deformation. |

| Cost-Effectiveness | Offers a balanced profile for reliable, durable heating in diverse applications at a competitive cost. |

Upgrade your lab's heating efficiency with KINTEK's advanced solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace systems like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs. Contact us today to discuss how our Nichrome-based and other heating elements can enhance your performance and reliability!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- What parameters does the IEC standard specify for heating elements? Ensure Safety and Performance

- What temperature ranges are recommended for SiC versus MoSi2 heating elements? Optimize Your Furnace Performance

- What is the difference between SiC and MoSi2? Choose the Right High-Temp Heating Element

- What is silicon carbide used for in heating applications? Discover Its High-Temperature Durability

- What is the operating temperature of SiC? Unlock Reliable Performance Up to 1600°C