In essence, Silicon Carbide (SiC) heating elements are highly durable ceramic components prized for their ability to operate efficiently at high temperatures. They are defined by their excellent thermal conductivity, mechanical strength, and resistance to chemical corrosion, making them a cornerstone technology for heat-intensive industrial processes in metal treatment, electronics manufacturing, and ceramics firing.

While often chosen for their high-temperature capabilities, the defining characteristic of SiC elements is their aging process. Understanding how their electrical resistance changes over time is the critical factor in their effective application and maintenance.

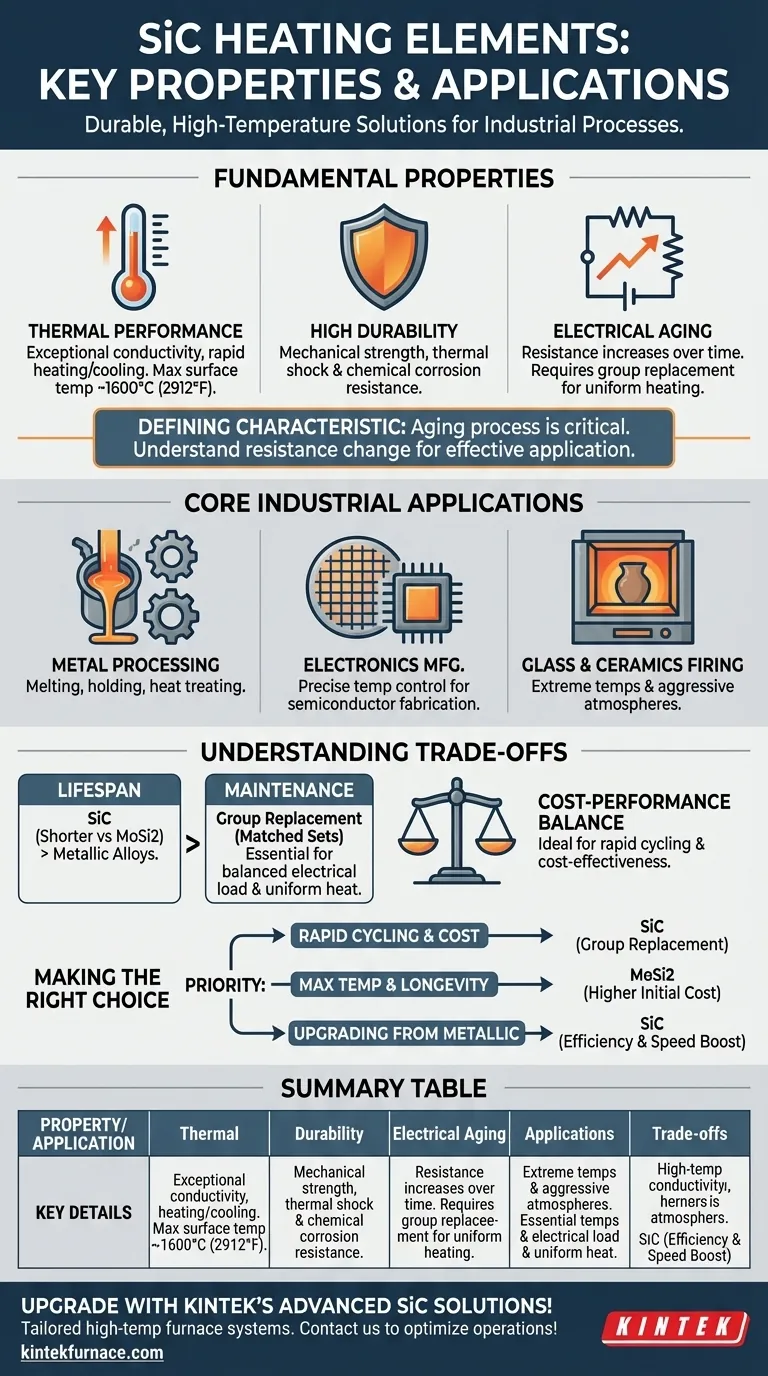

The Fundamental Properties of SiC Elements

To select the right heating element, you must first understand its core performance characteristics. SiC elements offer a unique combination of thermal, mechanical, and electrical properties.

Exceptional Thermal Performance

SiC elements possess exceptional thermal conductivity, which allows for very rapid heating times. This property is crucial for industries that rely on batch processing and require fast heating and cooling cycles.

They are capable of reaching a maximum element surface temperature of approximately 1600°C (2912°F). This translates to a maximum attainable furnace temperature in the range of 1530-1540°C, placing them in the high-temperature class of heating elements.

High Mechanical and Chemical Durability

These elements are known for their high mechanical strength and excellent resistance to thermal shock. This durability allows them to withstand the rigors of harsh industrial environments without frequent failure.

Furthermore, SiC is highly resistant to chemical corrosion, making it suitable for use in atmospheres that would degrade traditional metallic heating elements.

Electrical Characteristics and Aging

Unlike many other heating elements, the electrical resistance of SiC elements increases as they age. This is a critical operational characteristic.

Because of this change in resistance, the elements in a furnace must be aged at a similar rate to ensure a balanced electrical load and uniform heat distribution.

Core Industrial Applications

The robust properties of SiC elements make them indispensable in several key industries where high, consistent heat is non-negotiable.

Metal and Materials Processing

In metallurgy, SiC elements are used for processes like melting, holding, and heat treating of metals. Their ability to deliver consistent high temperatures is vital for achieving specific material properties.

Electronics and Semiconductor Manufacturing

The production of semiconductors requires extremely precise temperature control during processes like wafer fabrication. The fast thermal response and uniform heating of SiC elements make them ideal for these demanding applications.

Glass and Ceramics Firing

Manufacturing glass and firing advanced ceramics involves extreme temperatures and often chemically aggressive atmospheres. The durability and high-temperature stability of SiC make it a preferred choice for kilns and furnaces in this sector.

Understanding the Trade-offs

No technical solution is without its compromises. Choosing SiC elements requires a clear understanding of their operational limitations and maintenance protocols.

The Lifespan Consideration: SiC vs. MoSi2

While SiC elements have a significantly longer lifespan than traditional nickel-chromium alloys, they generally have a shorter operational life compared to Molybdenum Disilicide (MoSi2) elements, which can operate at even higher temperatures.

The Maintenance Protocol: Group Replacement

When a single SiC element fails, it cannot be replaced alone. Due to the change in resistance over their lifespan, a new element would have a drastically different resistance from the older ones, disrupting the parallel circuit and causing uneven heating.

Therefore, elements must be replaced in matched pairs or as a complete set to maintain furnace performance. This group replacement strategy is a key factor in calculating the total cost of ownership.

The Cost-Performance Balance

SiC elements represent an excellent middle ground. They are ideal for applications where cost is a significant driver and the absolute highest temperature capabilities of more exotic elements like MoSi2 are not strictly necessary.

Making the Right Choice for Your Application

Selecting the correct heating element is a decision based on balancing performance requirements with operational reality.

- If your primary focus is rapid cycling and cost-effectiveness: SiC is an excellent choice, provided you can accommodate the required group replacement maintenance schedule.

- If your primary focus is maximum operational temperature and longevity: You may need to evaluate alternatives like MoSi2, which can offer longer life and higher temperatures at a greater initial cost.

- If you are upgrading from traditional metallic elements: SiC offers a significant improvement in efficiency, temperature capability, and process speed.

Ultimately, choosing SiC is an informed decision based on your specific temperature needs, process cycle, and maintenance philosophy.

Summary Table:

| Property/Application | Key Details |

|---|---|

| Thermal Performance | High thermal conductivity, max surface temp ~1600°C, rapid heating/cooling |

| Durability | High mechanical strength, thermal shock resistance, chemical corrosion resistance |

| Electrical Aging | Resistance increases over time, requires group replacement for uniform heating |

| Applications | Metal processing (melting, heat treating), electronics (semiconductor fabrication), ceramics/glass firing |

| Trade-offs | Shorter lifespan vs. MoSi2, cost-effective for rapid cycling, requires matched set replacement |

Upgrade your high-temperature processes with KINTEK's advanced SiC heating solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored high-temperature furnace systems, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure precise alignment with your unique experimental needs, enhancing efficiency and reliability. Contact us today to discuss how our solutions can optimize your operations and drive success!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- What are the properties and capabilities of Silicon Carbide (SiC) as a heating element? Unlock Extreme Heat and Durability

- What are the advantages of using high purity green silicon carbide powder in heating elements? Boost Efficiency and Lifespan

- Why is silicon carbide resistant to chemical reactions in industrial furnaces? Unlock Durable High-Temp Solutions

- Why are silicon carbide heating elements essential in high-temperature industries? Unlock Reliable, Extreme Heat Solutions

- What makes silicon carbide heating elements resistant to chemical corrosion? Discover the Protective Oxide Layer