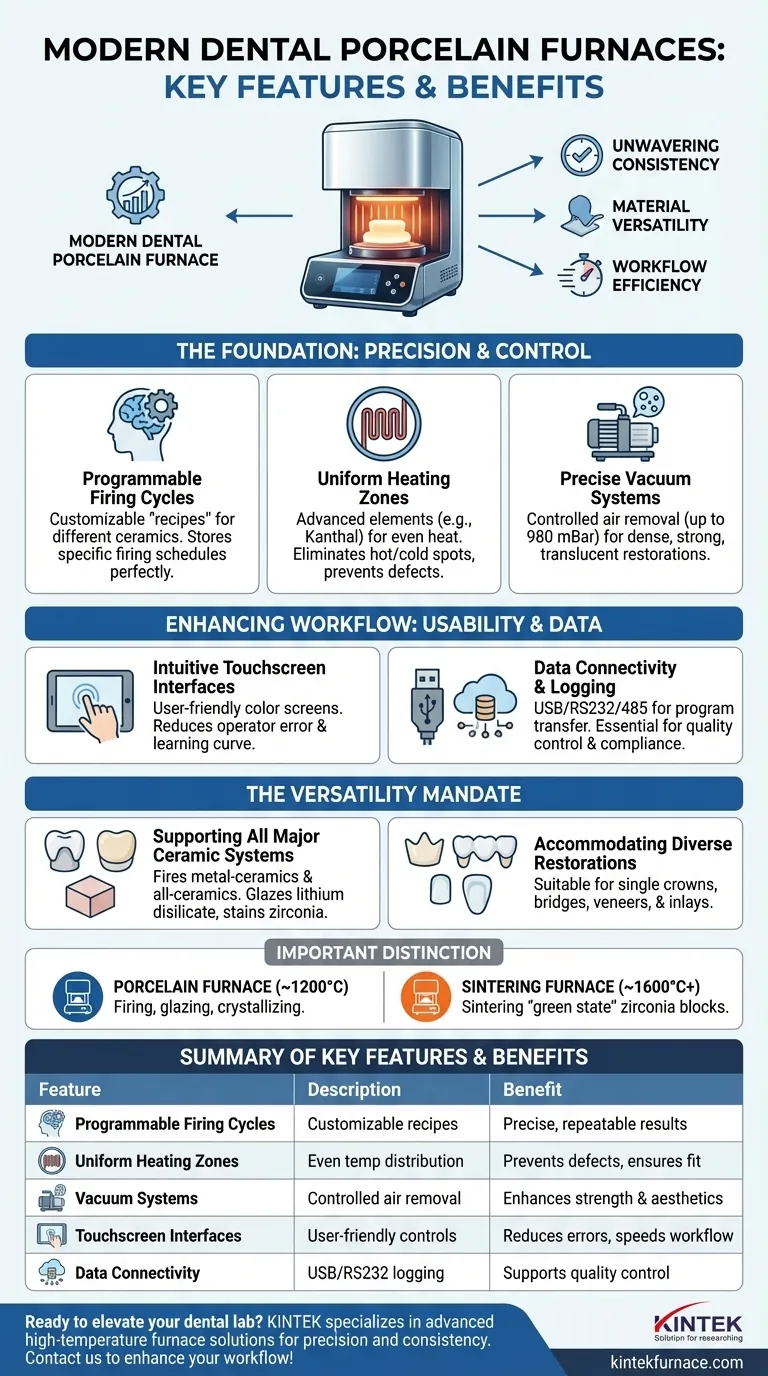

At their core, modern dental porcelain furnaces are electronically controlled, high-precision ovens defined by their programmability and ability to manage multiple materials. Key features include a uniform heating zone for consistency, a digital controller with a touch screen for ease of use, and a vacuum system to ensure restoration strength and density. They are engineered to fire a wide range of ceramics, from traditional porcelain-fused-to-metal (PFM) to advanced all-ceramics like lithium disilicate.

The collection of features in a modern porcelain furnace is not about technology for its own sake. It is about achieving three critical outcomes for any dental lab or clinic: unwavering consistency, material versatility, and workflow efficiency.

The Foundation: Precision and Control

The primary function of a porcelain furnace is to execute a firing cycle with absolute precision. This control is what transforms ceramic powder or blocks into strong, aesthetic, and perfectly fitting dental restorations.

Programmable Firing Cycles

A modern furnace's "brain" is its programmable controller. This allows technicians to create, store, and execute specific firing "recipes" tailored to different ceramic materials.

Each material, whether it's a PFM porcelain or a lithium disilicate glaze, has a unique manufacturer-specified firing schedule involving heating rates, hold times, and temperatures. Programmability ensures these schedules are followed perfectly every time.

Uniform Heating Zones

Consistency demands that every part of a restoration is heated to the exact same temperature. Modern furnaces use advanced heating elements, often made of Kanthal or Nichrome, to create a highly uniform heating zone.

This eliminates "hot spots" or "cold spots" that can cause internal stress, micro-cracks, or an improper fit in the final restoration.

Precise Vacuum Systems

Many firing cycles incorporate a vacuum to remove air from within the porcelain layers before they fuse. This process, called vacuum firing, is critical for creating dense, strong, and translucent restorations.

A modern furnace offers precise control over the vacuum level (up to 980 mBar) and its timing, which prevents bubbles and porosity that could compromise the restoration's integrity and aesthetics.

Enhancing the Workflow: Usability and Data

Beyond firing precision, modern furnaces are designed to integrate seamlessly into a digital dental workflow, making them easier to use and manage.

Intuitive Touchscreen Interfaces

Complex programming is now managed through user-friendly color touch screens. This drastically reduces the learning curve and minimizes the risk of operator error.

Technicians can select pre-loaded programs or create new ones with a few taps, streamlining the production process.

Data Connectivity and Logging

Features like USB ports and RS232/485 communication are now standard. These allow for the easy transfer of firing programs and, more importantly, the logging of temperature data for every cycle.

This data logging is essential for quality control, troubleshooting, and maintaining compliance documentation within the lab.

The Versatility Mandate

A modern dental lab rarely works with a single material. A furnace must be a versatile tool capable of handling the wide spectrum of ceramics used in restorative dentistry.

Supporting All Major Ceramic Systems

A key feature is the ability to process both metal-ceramics (PFM crowns) and all-ceramic restorations.

This includes firing porcelain onto metal frameworks made of precious or non-precious alloys, as well as glazing and crystallizing materials like lithium disilicate and staining pre-sintered zirconia.

Accommodating Diverse Restorations

The furnace must be suitable for a range of restoration types, from single crowns and multi-unit bridges to delicate laminate veneers and inlays fired directly on refractory models.

Understanding the Trade-offs and Distinctions

While highly capable, it is crucial to understand the specific role of a porcelain furnace and its limitations.

Porcelain Furnaces vs. Sintering Furnaces

A common point of confusion is the difference between a porcelain furnace and a zirconia sintering furnace. They serve two distinct purposes.

A porcelain furnace operates at lower temperatures (typically up to 1200°C) for firing, glazing, and crystallizing conventional ceramics.

A sintering furnace operates at much higher temperatures (up to 1600°C or more) and is used exclusively to sinter milled, "green state" zirconia blocks into their final, dense form. A lab working with zirconia requires both types of furnaces.

The Investment in Consistency

The advanced features of a modern furnace come at a higher initial cost. However, this investment provides significant long-term value.

The accuracy and consistency of these furnaces lead to fewer remakes, saving time and material costs. The ability to produce durable, high-quality restorations improves patient satisfaction and the reputation of the lab or clinic.

Making the Right Choice for Your Goal

Selecting a furnace depends entirely on the specific needs of your practice or laboratory.

- If your primary focus is high-volume production: Prioritize furnaces with fast heating rates, automation, and robust data connectivity to maximize throughput and workflow efficiency.

- If your primary focus is high-end aesthetics: Seek out a furnace with maximum programmability and the most precise temperature and vacuum control to allow for custom characterization.

- If your primary focus is chairside, in-office restoration (e.g., CEREC): Choose a compact, easy-to-operate furnace designed to complement your specific milling system for a fast and seamless workflow.

Ultimately, the right porcelain furnace translates technological precision into predictable, beautiful, and durable outcomes for your patients.

Summary Table:

| Feature | Description | Benefit |

|---|---|---|

| Programmable Firing Cycles | Customizable recipes for different ceramics | Ensures precise, repeatable results |

| Uniform Heating Zones | Even temperature distribution with advanced elements | Prevents defects and ensures fit |

| Vacuum Systems | Controlled air removal up to 980 mBar | Enhances strength and aesthetics |

| Touchscreen Interfaces | User-friendly digital controls | Reduces errors and speeds workflow |

| Data Connectivity | USB/RS232 for logging and transfer | Supports quality control and compliance |

| Material Versatility | Handles PFM, lithium disilicate, zirconia, etc. | Adapts to diverse dental applications |

Ready to elevate your dental lab's capabilities? KINTEK specializes in advanced high-temperature furnace solutions, including customizable porcelain furnaces tailored for dental ceramics. With our strong R&D and in-house manufacturing, we deliver precision, consistency, and efficiency to meet your unique needs. Contact us today to discuss how our products can enhance your workflow and outcomes!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- Why is calibration important for dental sintering furnaces? Ensure Perfect Restorations and Avoid Costly Failures

- How has the sintering process innovated dental zirconia applications? Boost Strength, Precision, and Efficiency

- What are the effects of overloading a dental sintering furnace? Ensure Predictable, High-Quality Zirconia Restorations

- What is the purpose of dental sintering furnaces? Transform Zirconia into Durable, High-Quality Dental Restorations

- What is a dental sintering furnace and what is its purpose? Achieve High-Strength Dental Restorations